A rotating micro radial displacement loading fatigue test equipment

A radial displacement and fatigue test technology, applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problem of difficult to accurately control the loading accuracy, difficult to guarantee the uniformity of the load, and the radial displacement cannot be automatically compensated. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

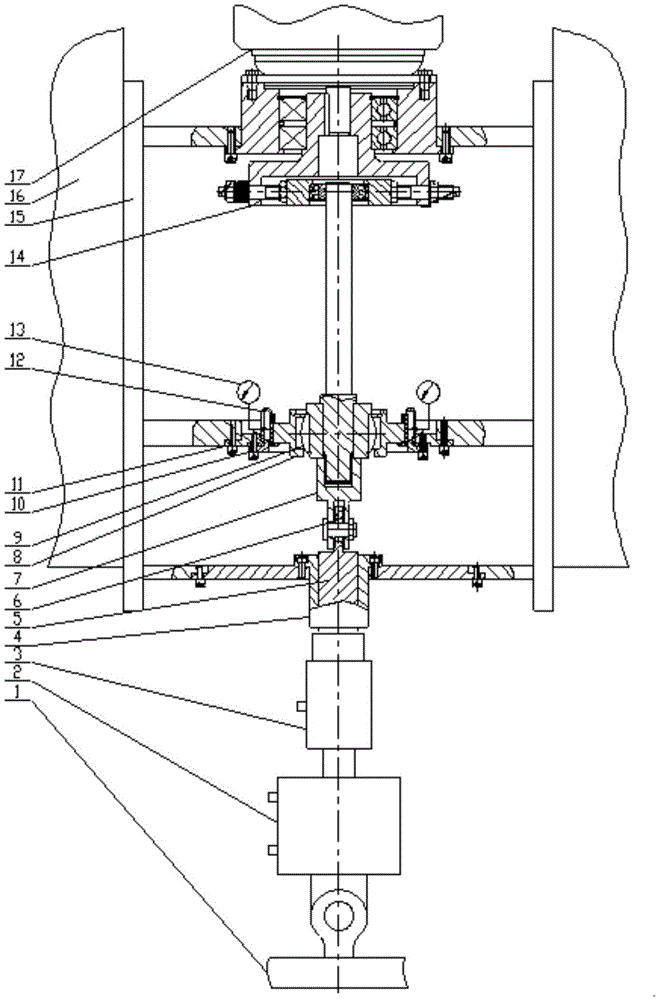

[0017] The present invention provides a rotating small radial displacement loading fatigue test equipment, characterized in that: the rotating small radial displacement loading fatigue testing equipment includes a platform 1, an actuator 2, a dynamometer 3, and a linear bearing 4 , guide rod 5, joint bearing 6, loading rod assembly 7, simulated bearing 8, joint bearing 9, simulated special-shaped bearing 10, simulated bearing seat 11, elastic support structure 12, dial indicator 13, bending component 14, load-bearing frame 15, column 16, motor 17;

[0018] Among them: the load-bearing frame 15 is installed on the column 16, the elastic support structure 12 is installed on the load-bearing frame 15 through the simulated bearing seat 11 and the simulated special-shaped bearing 10; the actuator 2 installed on the platform 1 passes through the dynamometer 3, The guide rod 5, the loading rod assembly 7, the joint bearing 9 and the simulated bearing 8 apply an axial load to the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com