Method for predicting the remaining service life of a saw band, and bandsaw machine

A technology of band saw machine and saw band, which is applied in the direction of sawing machine accessories, sawing machine devices, measuring devices, etc., and can solve problems such as high cost, prone to sensor failure, and extensive maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

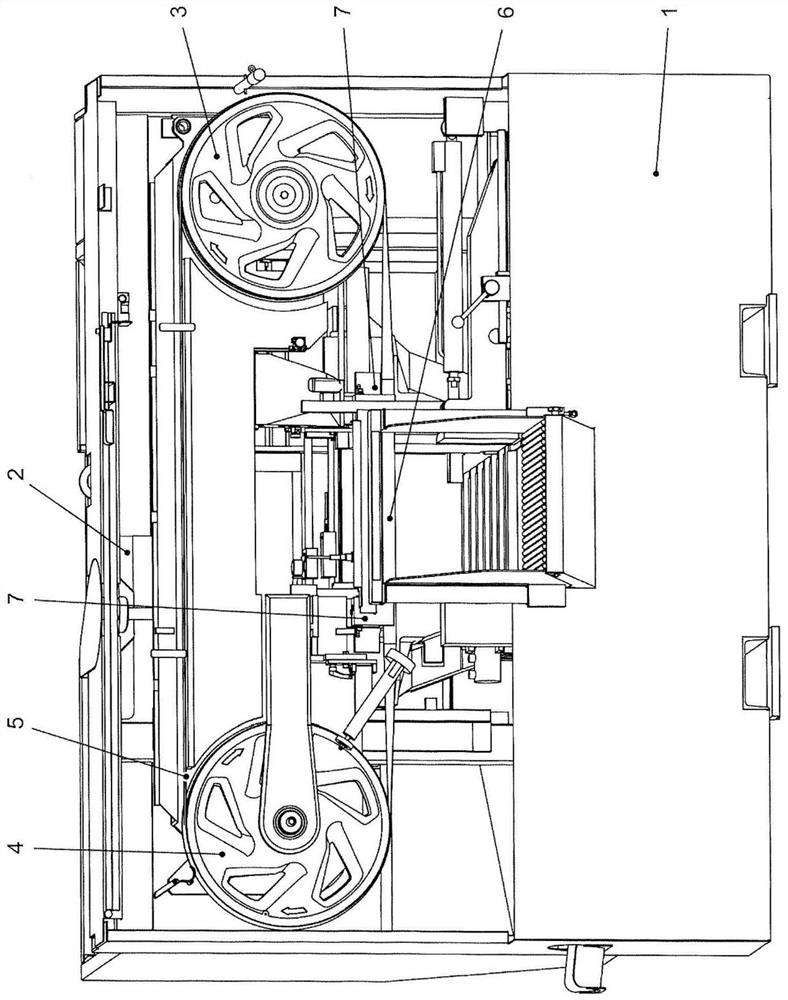

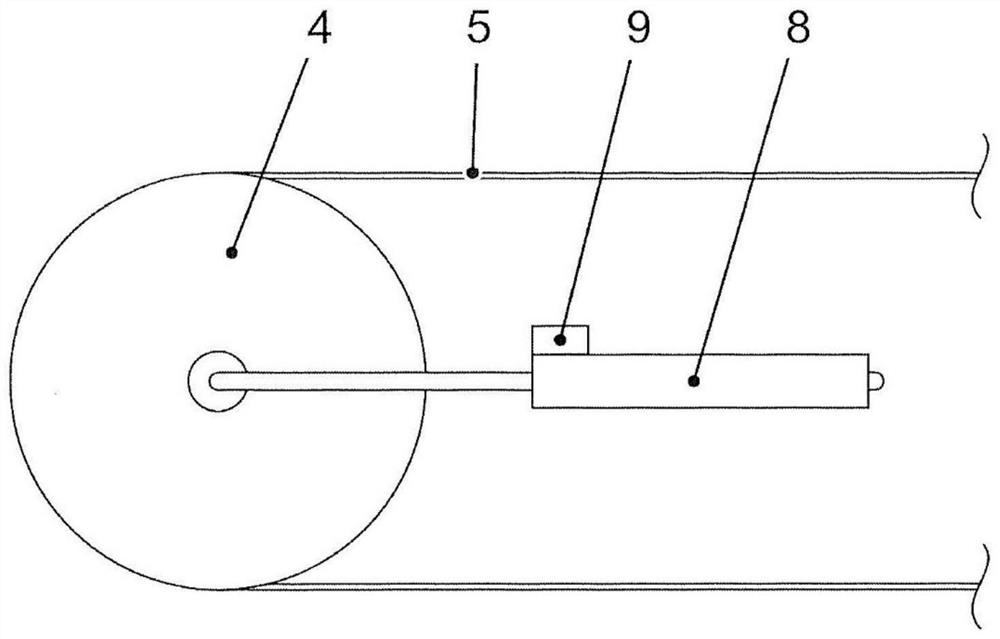

[0049] figure 1 Schematically shows a band saw machine, the band saw machine has a lower saw part 1 and an upper saw part 2, the workpiece to be sawed is placed on the lower saw part 1, and the upper saw part 2 can be positioned relative to The lower saw part 1 moves up and down. Two traveling wheels 3 , 4 are arranged in the upper saw part 2 , namely the stationary traveling wheel 3 and the horizontally movable traveling wheel 4 in this case, at least one of which is driven. The saw band 5 is tensioned around these running wheels 3 , 4 . In order to carry out the sawing movement, the saw band revolves around two running wheels 3 , 4 .

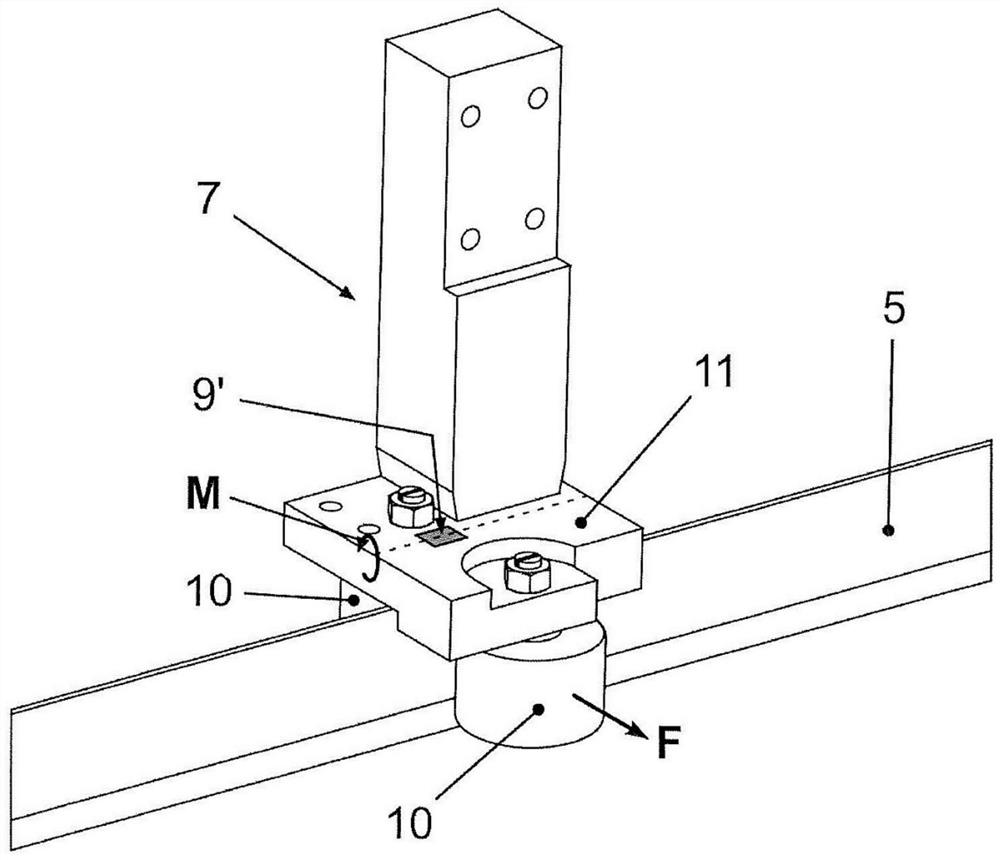

[0050] In the sawing region 6 in which the saw band 5 comes into contact with the workpiece by lowering the upper saw part 2 , the saw band 5 is swiveled by means of the two belt guides 7 from a rotation parallel to the axis of the travel wheels 3 , 4 and in the present case horizontally oriented. The movement plane is rotated into the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com