Distributed optical fiber testing method for seepage in porous media structures

A technology of distributed optical fiber and porous media, applied in suspension and porous material analysis, permeability/surface area analysis, measurement devices, etc., can solve problems such as immature theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

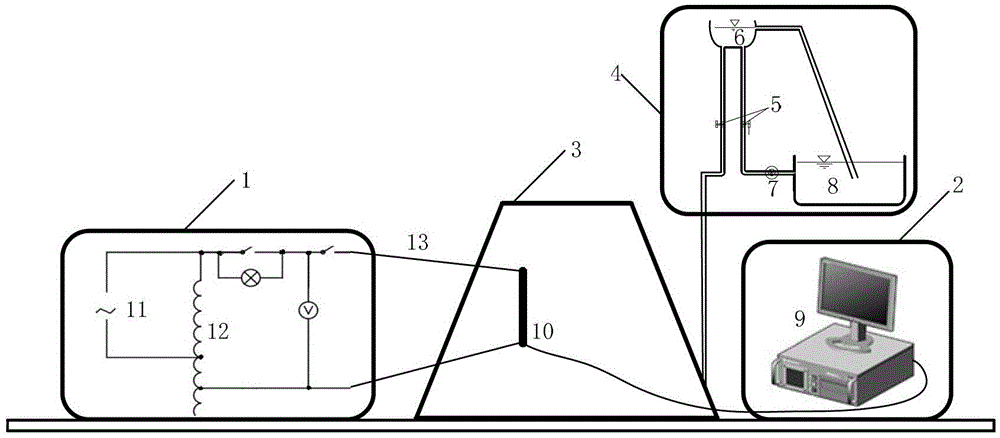

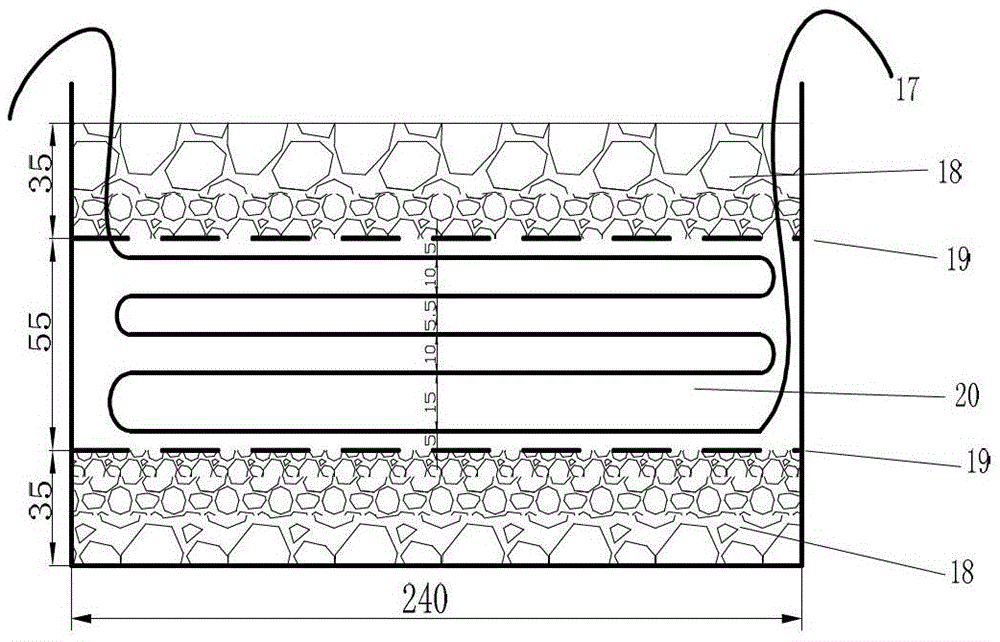

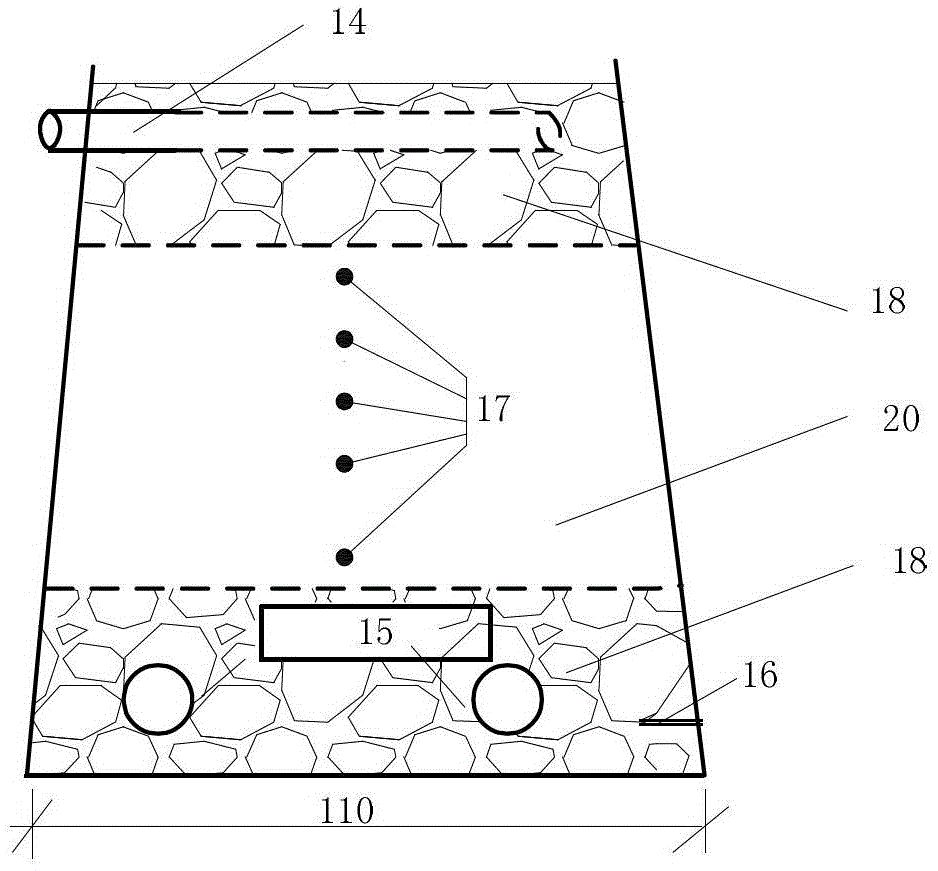

[0050] Embodiment 1: The porous media structure seepage velocity monitoring device based on the total heat transfer coefficient of the present invention, the schematic diagram of the device is as follows figure 1 As shown, it includes a heating system 1, a distributed optical fiber temperature sensing system 2, a porous medium structure model tank 3 embedded with a monitoring optical fiber, and a water outlet system 4; the heating system 1, the distributed optical fiber temperature sensing system 2 and the water outlet system The system 4 is respectively connected with the porous medium structure model tank 3 .

[0051] The heating system 1 is a parallel circuit mainly composed of an AC power supply 11, a voltage regulator 12, and a load heating resistance wire 13. The monitoring optical fiber is heated through the load heating resistance wire 13, and the heating power is controlled by controlling the voltage through the voltage regulator.

[0052] The distributed optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com