Optical fiber F-P cavity high-voltage sensor

A high-pressure sensor, F-P technology, applied in the direction of fluid pressure measurement, instruments, and measuring devices using optical methods, to achieve stable performance, high frequency response, and ensure measurement accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

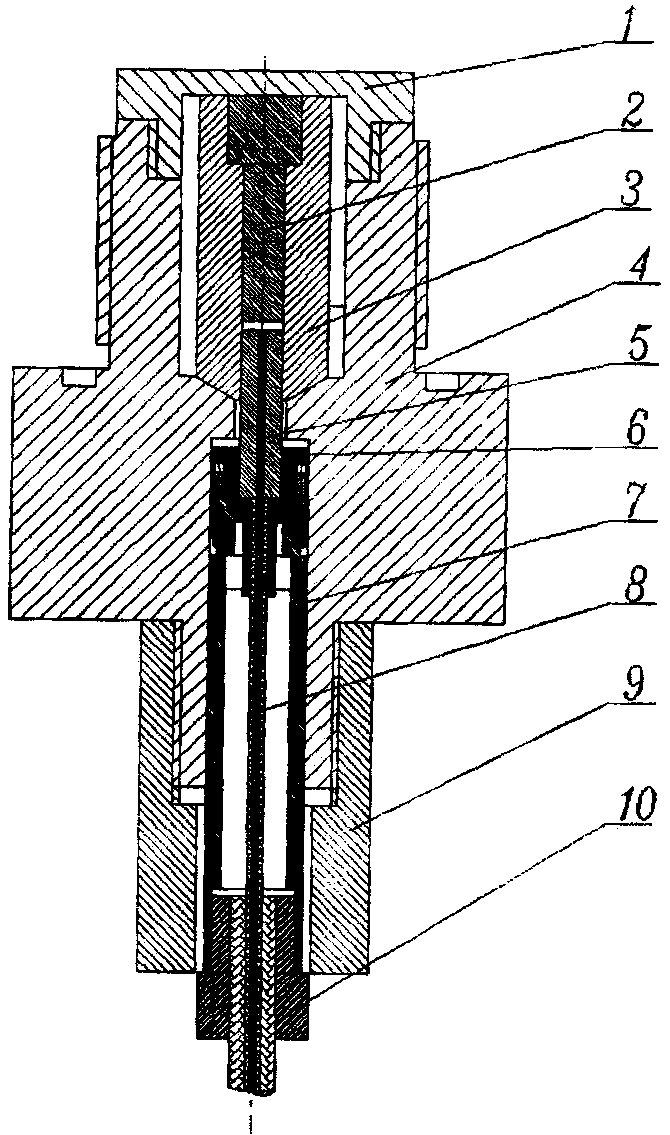

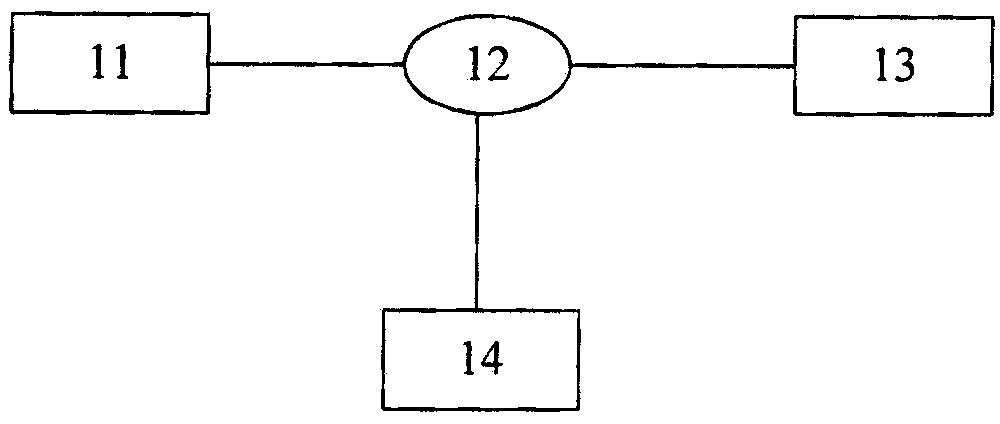

[0015] The accompanying drawings illustrate specific embodiments of the present invention.

[0016] Such as figure 1 As shown: the present invention consists of a diaphragm body 1, an upper ceramic ferrule 2, a support cylinder 3, a mounting shell 4, a lower ceramic ferrule 5, a ferrule fixing cap 6, a guide positioning rod 7, an optical fiber 8, a protective cover 9, The fixed joint 10 forms. The diaphragm body 1 and the front end of the installation housing 4 are fixed to form the pressure-sensitive surface of the sensor. The upper ceramic ferrule 2 is placed in the support cylinder 3. The upper end surfaces of the two are flush and in close contact with the diaphragm body 1. The support cylinder 3 A conical contact surface is adopted between the lower end surface of the lower end face of the housing and the installation shell 4, the lower ceramic ferrule 5 (with pigtail) is fixed together with the guide positioning rod 7 through the ferrule fixing cap 6, and inserted into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com