Double-temperature condensing two-stage compressing heat pump system

A two-stage compression and heat pump system technology, applied in the field of heat pumps, can solve the problems of large heat transfer temperature difference, large compressor compression ratio, large energy loss, etc., to reduce exhaust temperature, reduce energy loss, and reduce heat transfer temperature difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

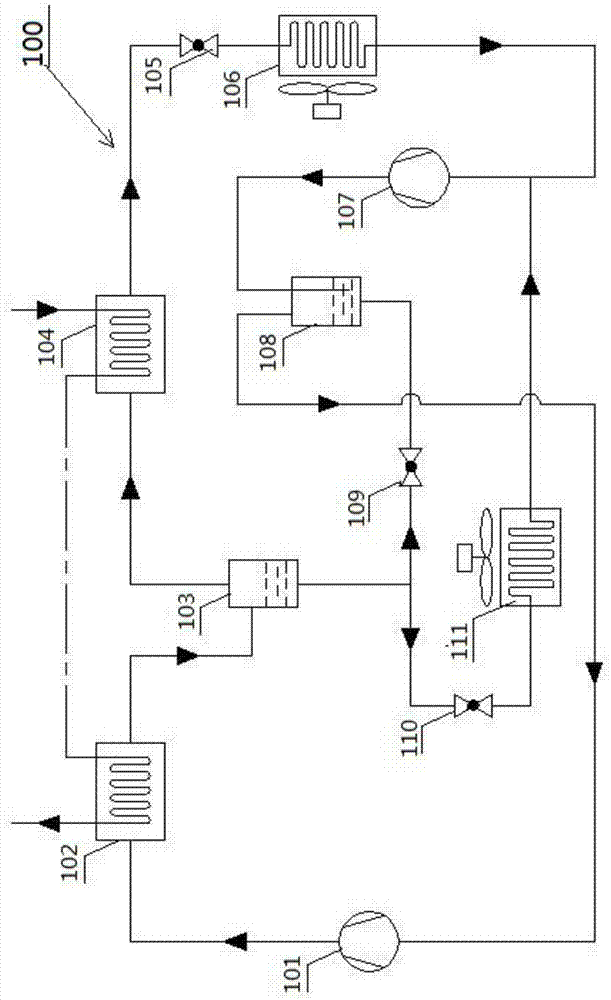

[0023] figure 1 It is a schematic diagram of the overall structure of the dual-temperature condensation two-stage compression heat pump system in Embodiment 1.

[0024] like figure 1 As shown, the decondensation single-temperature evaporation heat pump system 100 includes: a high-pressure stage compressor 101, a high-temperature stage condenser 102, a dephlegmator 103, a low-temperature stage condenser 104, a first throttle valve 105, a low-temperature stage evaporator 106, a low-pressure Stage compressor 107, heat exchanger 108, second throttle valve 109, third throttle valve 110, high temperature stage evaporator 111 and connecting pipelines.

[0025] The outlet of the high-pressure stage compressor 101 is connected with the high-temperature stage condenser 102, and the high-temperature stage condenser 102 is connected with the decondenser 103. It is connected with the second throttle valve 109 and the third throttle valve 110 respectively, the low temperature stage conden...

Embodiment 2

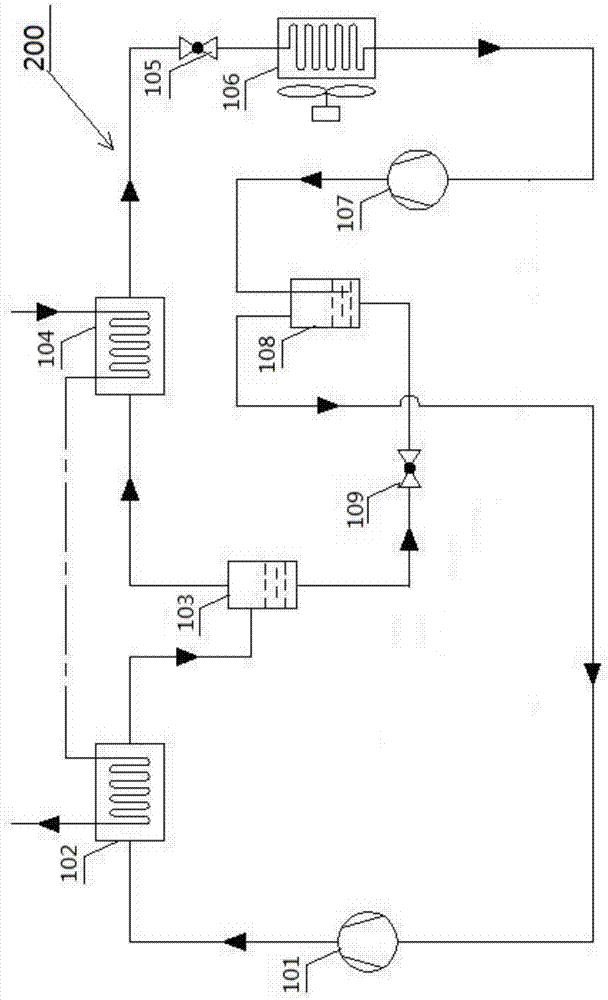

[0035] figure 2 It is a schematic diagram of the overall structure of the dual-temperature condensation two-stage compression heat pump system in Embodiment 1.

[0036] In the second embodiment, the same structures as those in the first embodiment are given the same numbers, and the same descriptions are omitted.

[0037] Such as figure 2 As shown, the dual-temperature condensation two-stage compression heat pump system 200 removes the branch circuit composed of the third throttle valve 110 and the high-temperature stage evaporator 111 on the basis of the first embodiment.

[0038] The function and effect of embodiment two:

[0039] Compared with Embodiment 1, this Embodiment 2 removes the branch structure composed of the high-temperature stage evaporator 111 and the third throttle valve 110 on the basis of Embodiment 1, and only has one evaporator 106, so this embodiment The structure of the second embodiment is more compact, and the function and effect of the second emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com