Electrical oil heater with high thermal efficiency

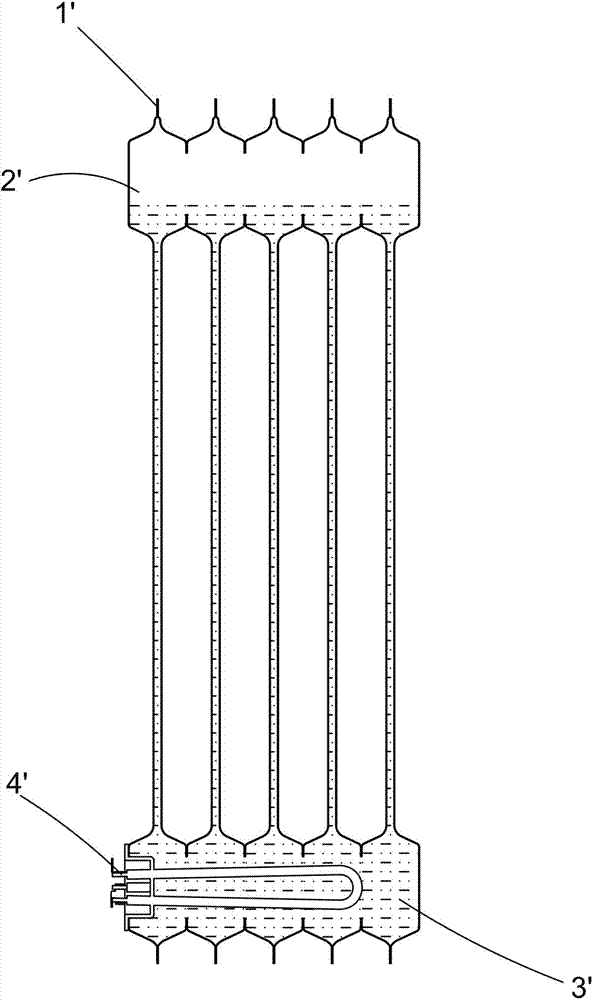

An electric heating oil heater and thermal efficiency technology, applied in the field of electric heaters, can solve the problems of increased processing difficulty, high production cost, unstable convection between heat sinks, etc., and achieve the effect of improving heat dissipation effect and increasing heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

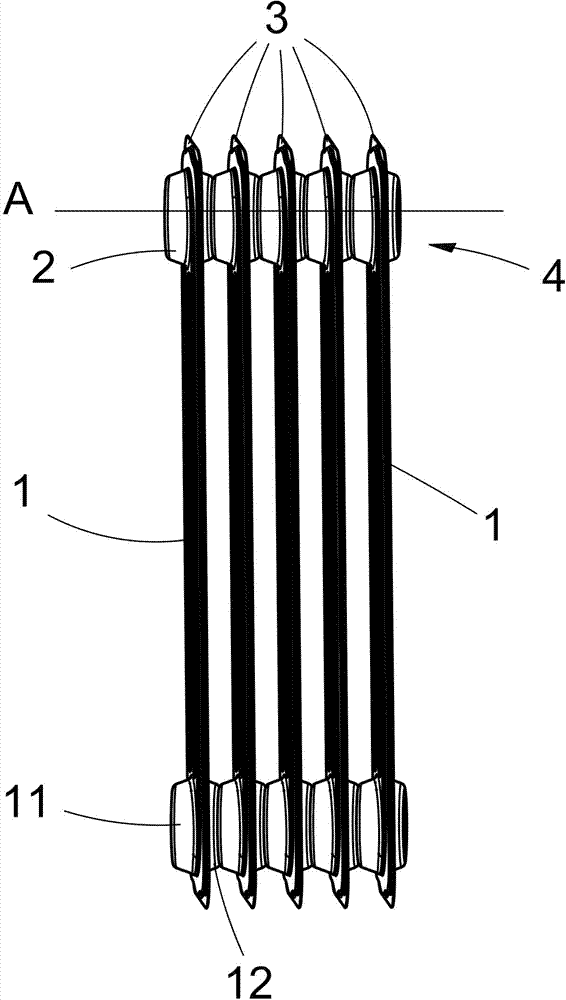

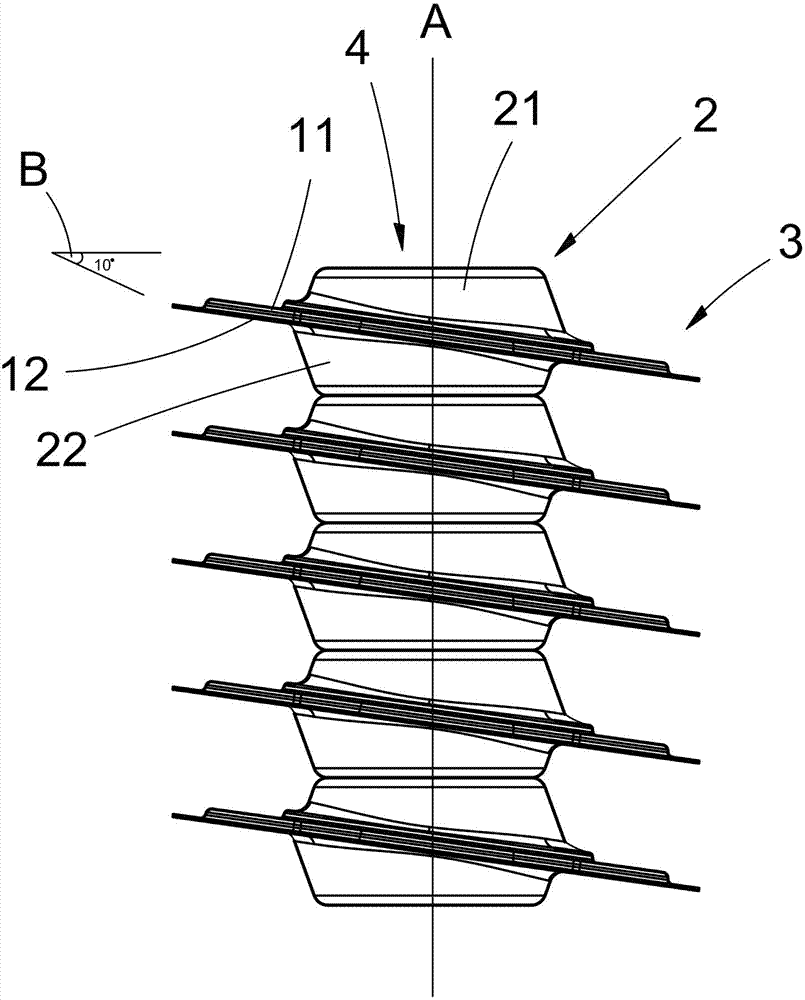

[0031] According to the above structure derived as Figure 5 In the second embodiment of the present invention shown, the oil storage bag 2 is taken as the vertical line A, and the cooling fins 3 are located on the side vertical surface of the oil storage bag 2, forming an angle with the vertical line A , the upper heat sink 11 is welded to the lower heat sink 12, so that the upper oil storage bag 21 and the lower oil storage bag 22 are oppositely installed, and the upper high bag part 211 is oppositely installed on the lower low bag part 222, the upper lower bag The bag part 212 is oppositely installed on the lower high bag part 221. At the same time, the upper oil storage bag 21 and the lower oil storage bag 22 are respectively arranged as upper and lower two oil passages communicating with each other, so as to increase the flow of heat transfer oil on the heat sink 1. flow within. The upper and lower groups of oil storage bags 2 are used to incline the heat dissipation fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com