Fastening block

A fixed seat and seat body technology, applied in the direction of threaded fasteners, connecting components, nuts, etc., can solve the problems of inconvenient removal of the fixed seat, inconvenient disassembly, etc., to facilitate disassembly, ensure drying, and prevent oxidation and rust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

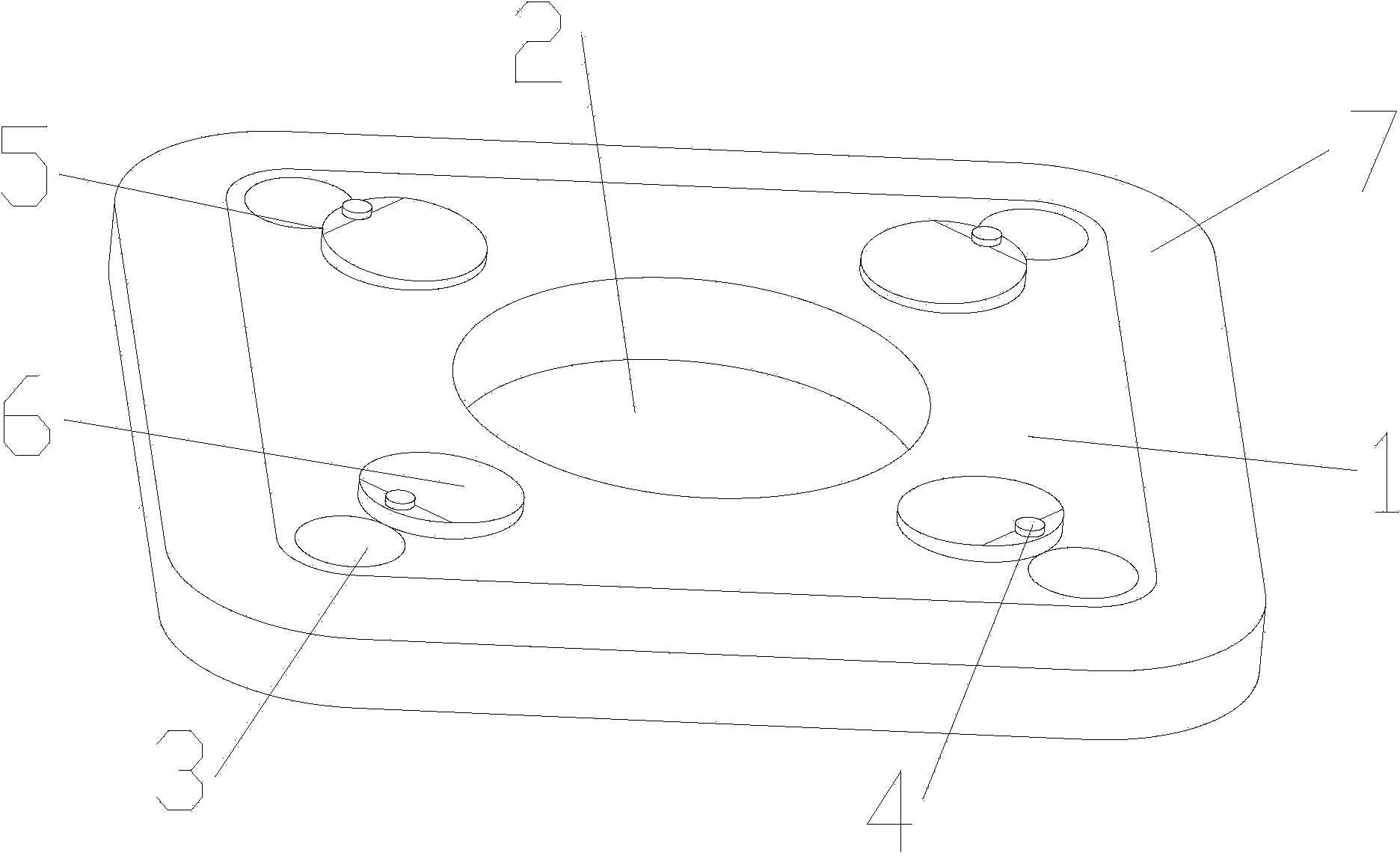

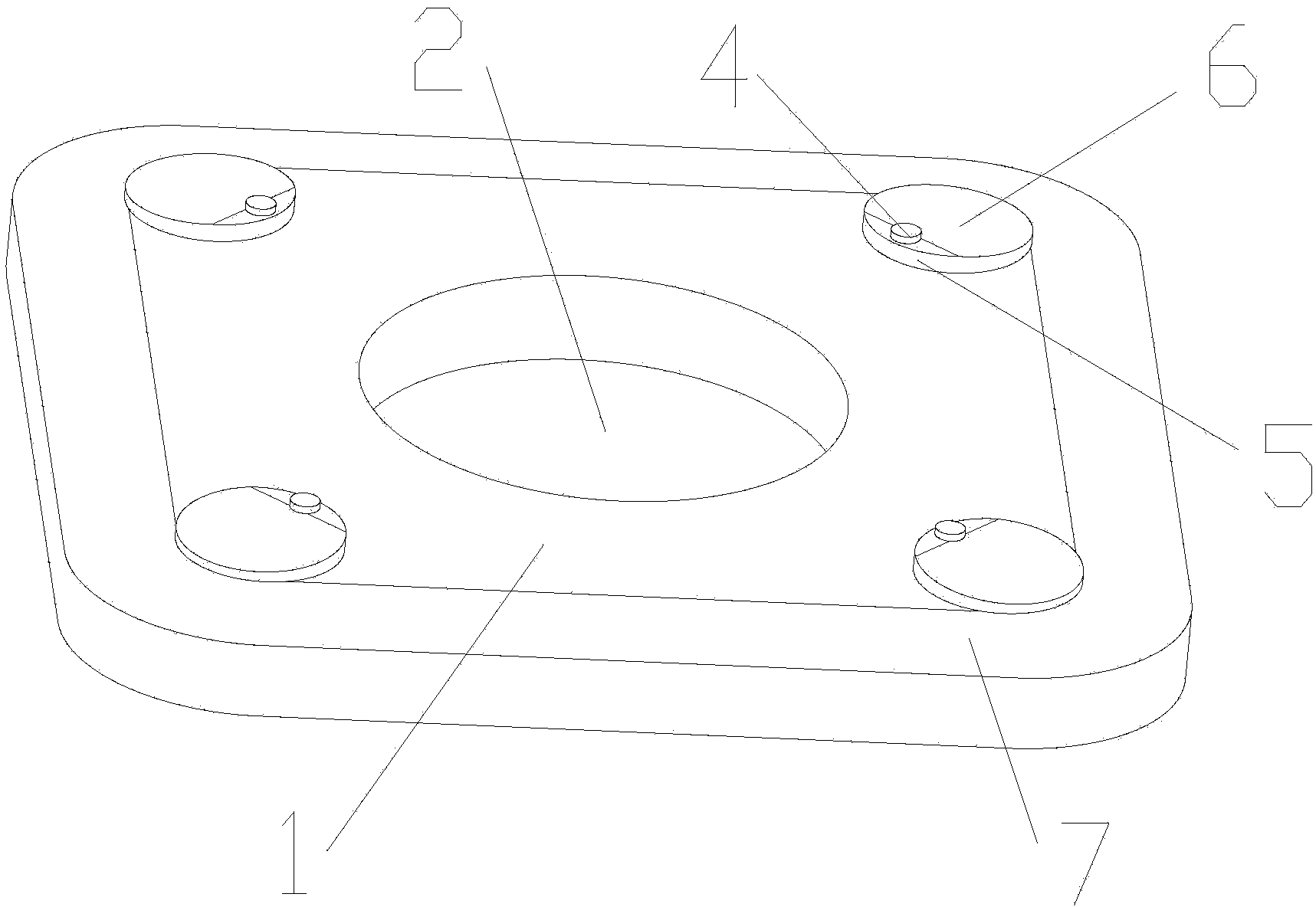

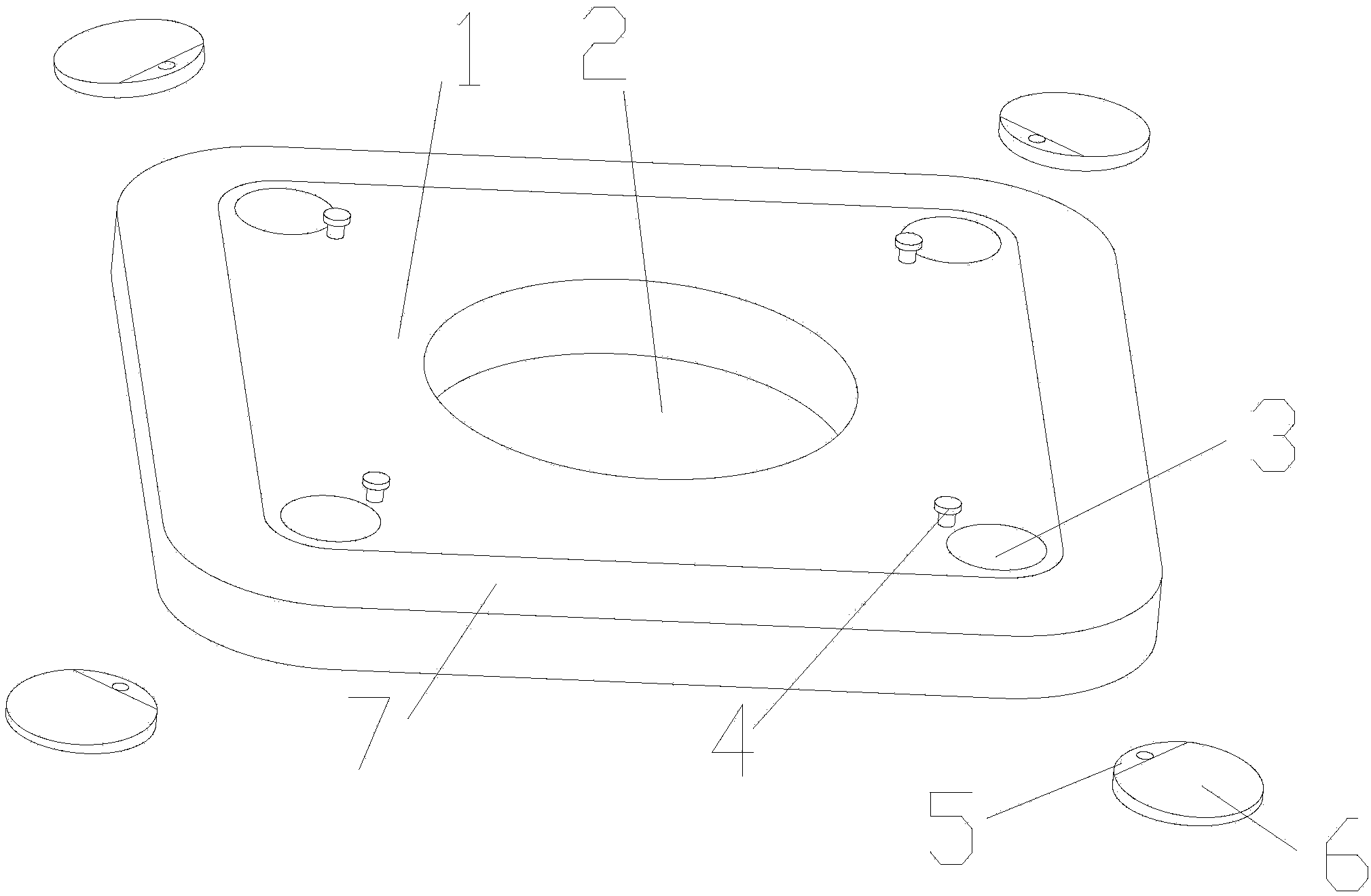

[0015] attached Figure 1-3 The fixing seat described for the invention includes a seat body 1, the seat body 1 is provided with a cuboid structure, and a mounting hole 2 is opened in the middle; the seat body 1 is also provided with positioning mounting holes 3 at its four corners ; The base body 1 is also fixed with a rotating rod 4 at a position adjacent to the positioning mounting hole 3, and a cover plate 5 that can rotate around it is set on the rotating rod 4, and when the cover plate 5 is turned to the position where the positioning mounting hole 3 is located At the position, the cover plate 5 covers the positioning mounting hole 3 .

[0016] Wherein the upper surface of the cover plate 5 is provided with a slope 6, and the slope 6 starts to slope downward from the connection part of the cover plate 5 and the rotating rod 4, and the edge of the upper surface of the seat body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com