Drilling, cutting, pressing and pumping method

A drilling cutting and drilling rig technology, which is used in earth-moving drilling, gas discharge, safety devices, etc., can solve the problems of small effective impact range of drilling, large drilling workload, and poor coal seam permeability, and achieve safe drainage. , Fast drain, and the effect of increasing the gas drain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

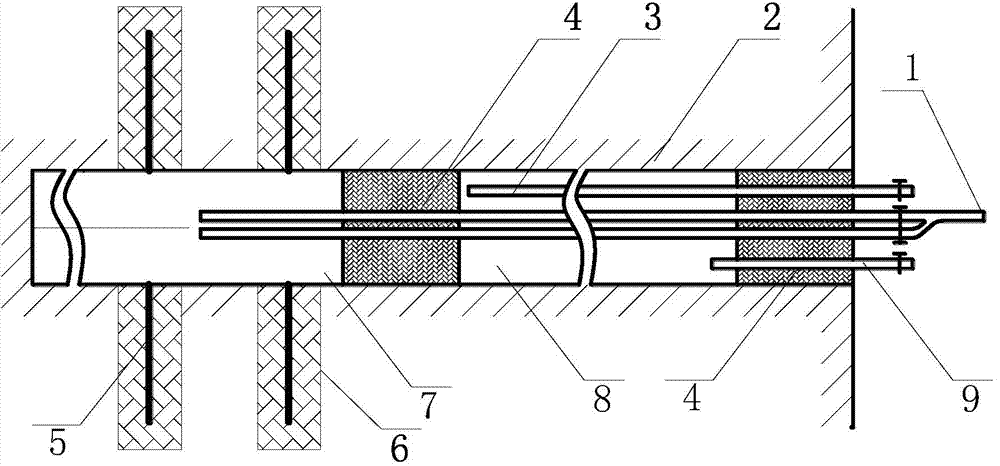

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] Drilling, cutting, pressing and pumping method of the present invention, concrete steps are as follows:

[0021] a. First, use a drilling rig to drill a drill hole 7 to the design depth in the coal seam 2 in front of the coal mining or driving face;

[0022] b. Exit the drill pipe, replace the hydraulic slitting drill bit and continue drilling until reaching the bottom of the borehole, and retreat the drill pipe to perform hydraulic slitting at intervals to form multiple annular main cracks 5 in the borehole; perform hydraulic slitting at the intervals The time is 20 minutes; the coal body is artificially disturbed through the slit to form a space for pressure relief and permeability enhancement, and improve the air permeability of the coal seam;

[0023] c. After the hydraulic cutting is completed, the opening of the drill hole 7 is blocked. The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com