Underground Mining Cutting Uphill Trough Method

A technology of pulling and cutting holes, applied in underground mining, surface mining, special mining, etc., can solve the hidden safety hazards of mine workers, reduce mining efficiency and other problems, improve mine safety and production efficiency, avoid dangerous operations, The effect of reducing the number of pulls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples further illustrate the technical solutions of the present invention, which are not intended to limit the protection scope of the present invention.

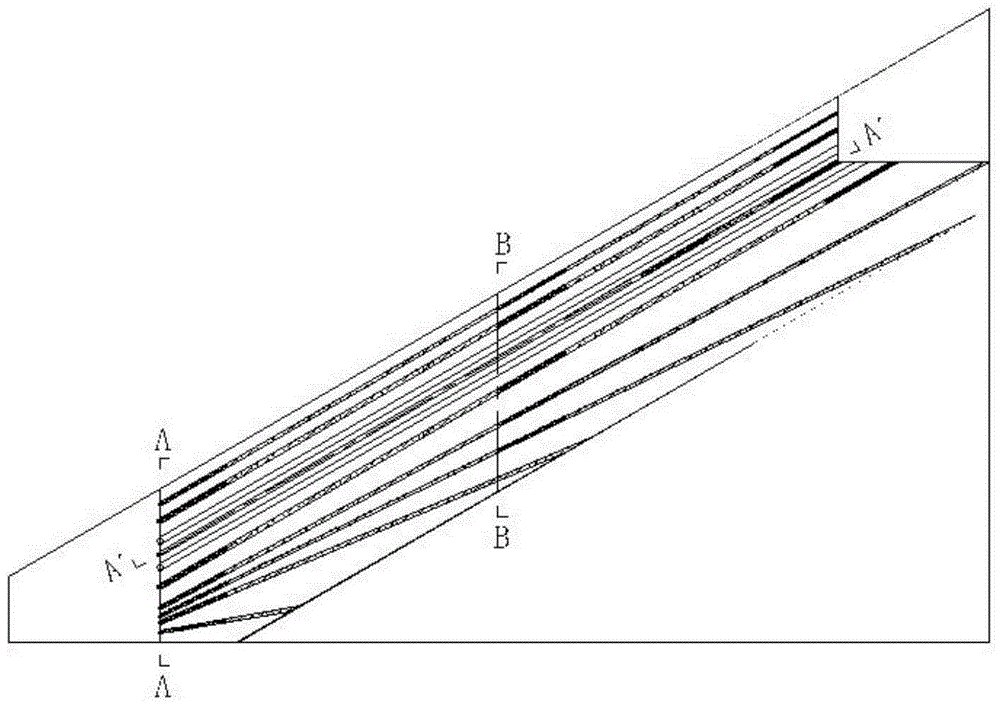

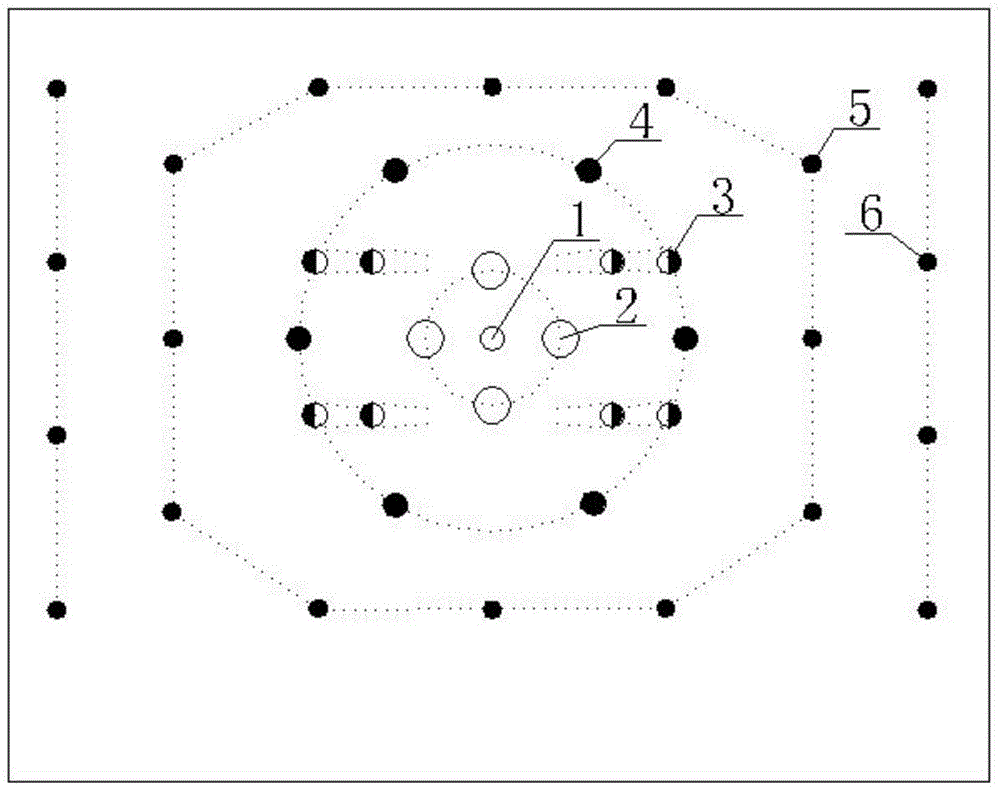

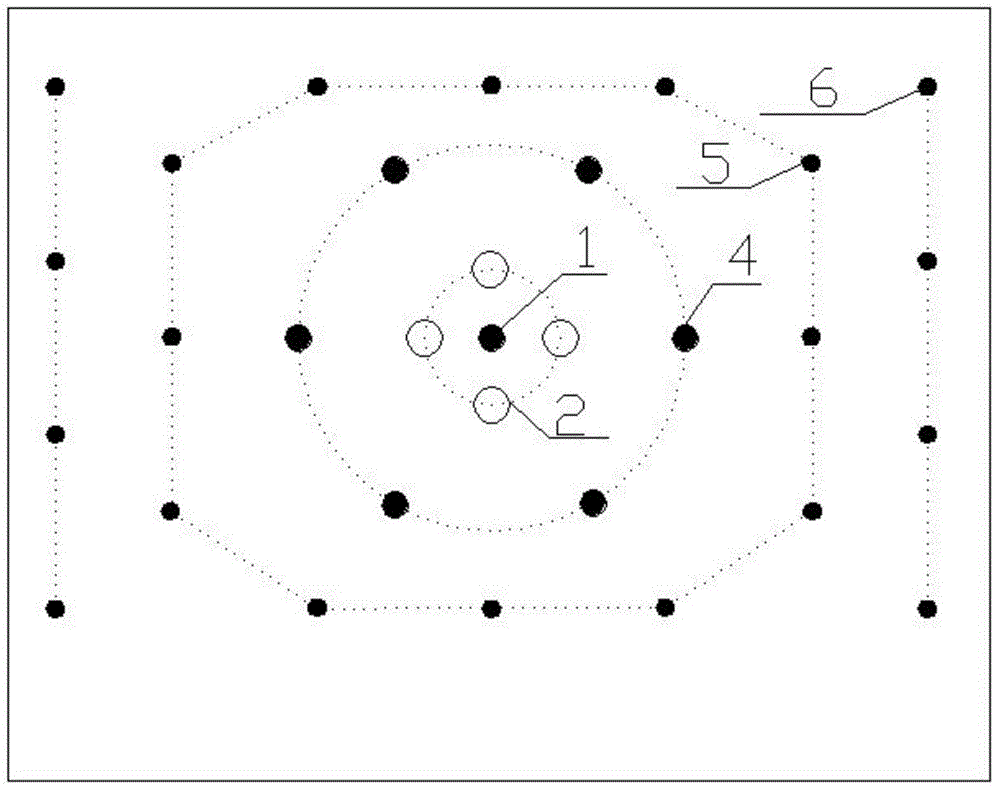

[0021] refer to figure 1 , 2 As shown in , 3 and 4, the underground mining method of cutting up the mountain and pulling grooves adopts the combination of graded cutting and straight eye and oblique eye composite cutting, and graded charge blasting at one time; wherein, the straight eye cutting hole 4 runs through the entire length of cutting up the mountain And it is divided into two stages of charging, and the oblique hole 3 is inclined to the blasting plane and extends toward the center hole 1. Cutting with oblique eyes can improve the effect of crushing and throwing movement of ore rock in the groove cavity, and create a good compensation space for the second level of straight eye cutting.

[0022] refer to figure 1 , 2 , Shown in 3,4, above-mentioned scheme, described straight eye cutout is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com