Composite material structural piece and manufacturing method thereof

A technology of composite materials and structural parts, applied in the direction of bridge materials, bridge parts, bridges, etc., can solve the problems of low impact resistance, local instability, reduced bridge bearing capacity, etc., to achieve good lateral strength, good overall stiffness, good The effect of local load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a method for preparing a composite material structure, comprising:

[0053] a) Wrap the flexible fiber reinforced material on the surface of the core to form a core covered with the flexible fiber reinforced material;

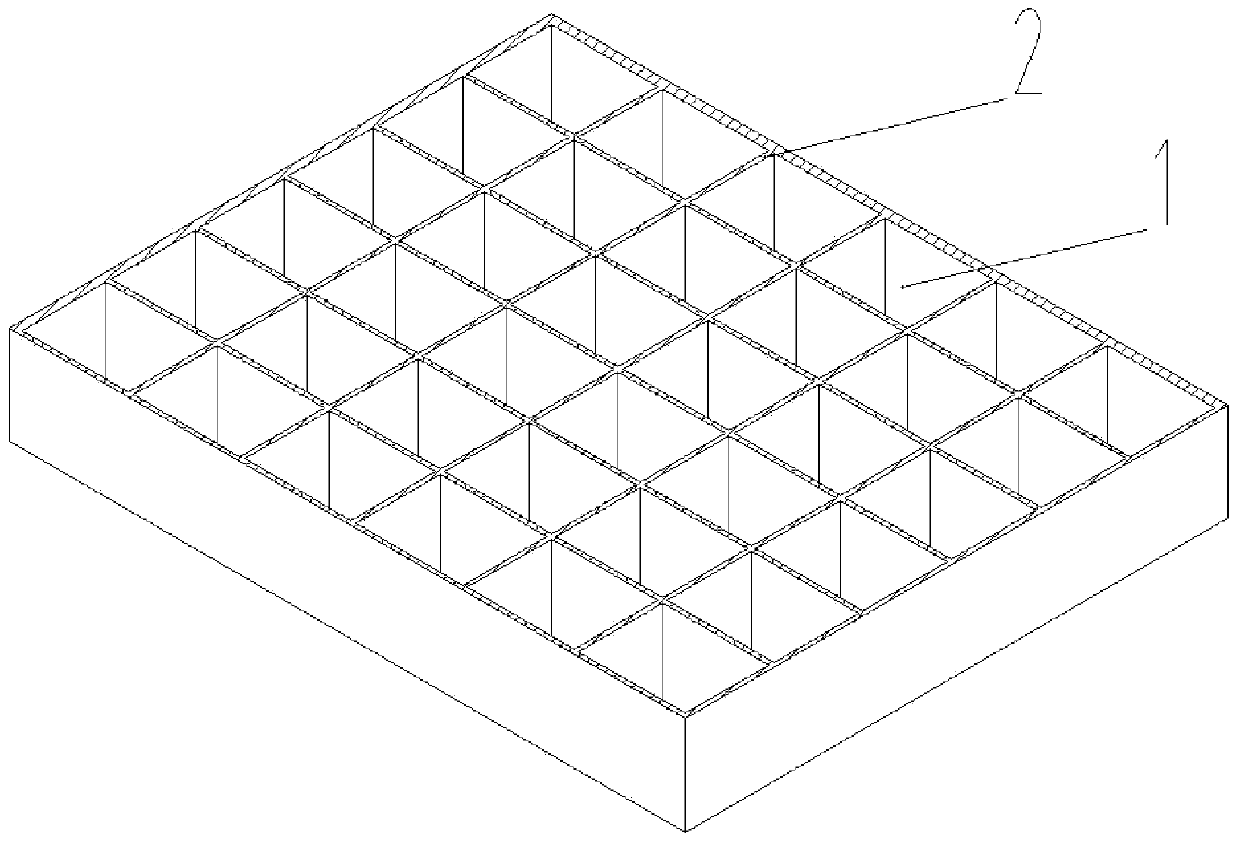

[0054] b) A plurality of cores covered with flexible fiber reinforced materials are arranged in a grid pattern, injected with adhesive resin and cured to obtain a composite material structure.

[0055] In the present invention, firstly, the flexible fiber reinforced material is coated on the surface of the core body to form a core body whose surface is covered with the flexible fiber reinforced material. The present invention has no special limitation on the coating method. One integral flexible fiber reinforced material can be used to completely cover the surface of the core body, or several flexible fiber reinforced materials can be used to respectively cover several surfaces of the core body, and finally Cover the ...

Embodiment 1~3

[0089] The core body is wrapped with 4 layers of biaxial cloth, and then the 5 core bodies are connected in the transverse direction by overlapping, and the first module is obtained after infusion molding with unsaturated polyester; the two second modules are obtained by using 4 layers of biaxial cloth. One module is wrapped along the longitudinal direction, and the mesh-like spline is obtained after infusion molding with unsaturated polyester, and its size is: length 220mm*height 20mm*width 30mm.

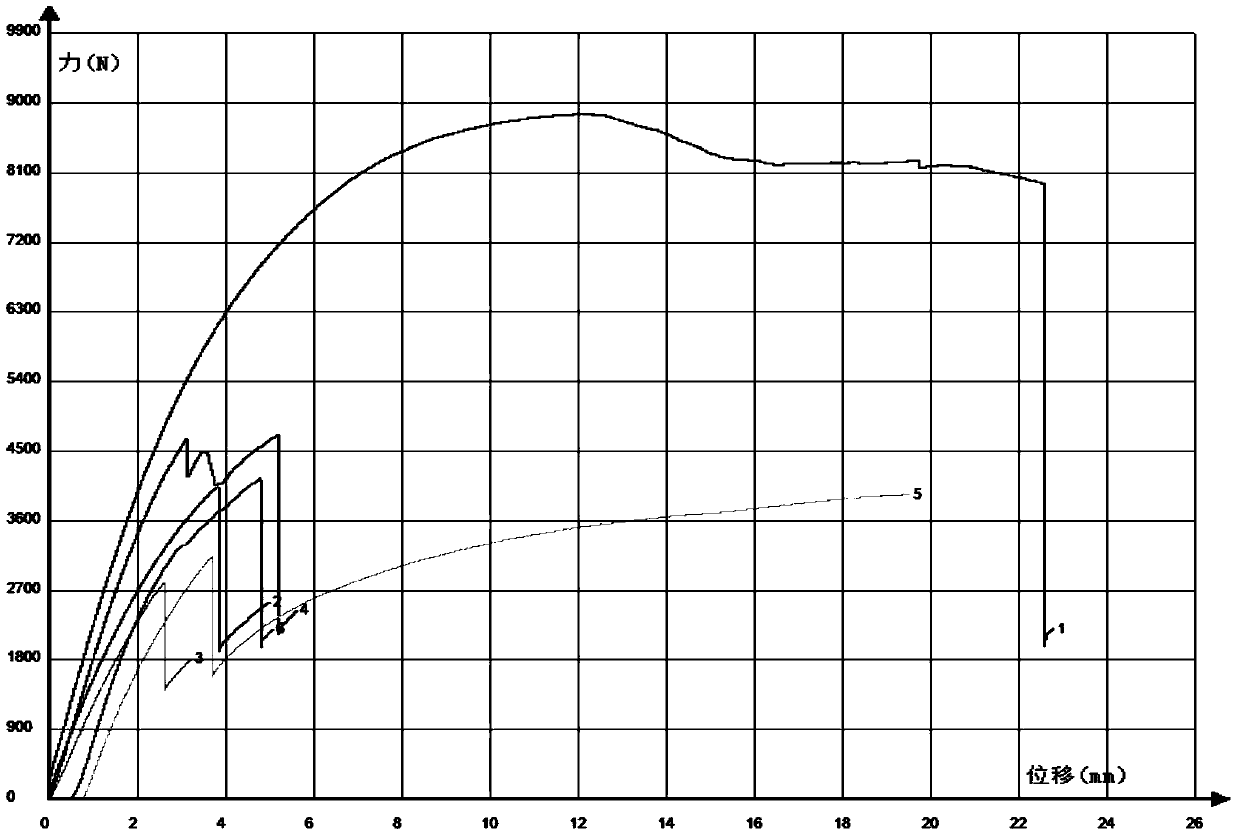

[0090] The universal testing machine of Meters Industrial Systems Co., Ltd. is used to test the performance of the grid-shaped spline, and the results can be found in Figure 4 and Table 3, Figure 4 The force-displacement curves of the grid-shaped splines provided in Examples 1-3 of the present invention, Table 3 shows the dimensions and performance tests of the grid-shaped splines provided in Examples 1-3 of the present invention.

[0091] Table 3 The dimensions and performance ...

Embodiment 4~6

[0095] The core body is wrapped with 4 layers of biaxial cloth, and then several core bodies covered with biaxial cloth are arranged in a grid pattern, and each core body arranged in the longitudinal direction is covered with biaxial cloth. The biaxial cloth Wrap the adjacent surface of each core, the opposite surface of the adjacent surface, and a bottom surface between the adjacent surface and the opposite surface, and the biaxial cloth covers the bottom surface on different planes of the adjacent cores; use biaxial cloth to cover For each core body arranged in a transverse direction, the biaxial cloth covers the adjacent surface of each core body, the opposite surface of the adjacent surface, and a bottom surface between the adjacent surface and the opposite surface, and the biaxial cloth covers the adjacent core body The bottom surface on different planes is infused with unsaturated polyester to obtain a grid-like spline, and its size is: length 220mm*height 20mm*width 30mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com