Pure-organic long-afterglow composite material and preparation method thereof

A composite material and captain technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of toxicity in the preparation process, scarcity of preparation materials, complicated preparation process, etc., achieve simple preparation process, good biocompatibility, overcome the Effects of consumption of non-renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of pure organic long afterglow composite material includes the following steps:

[0021] (1) Under inert atmosphere, pyrolyze disodium edetate at 200-400°C for 2-4 hours to obtain a black fluffy solid;

[0022] (2) Dissolve the black fluffy solid ultrasonically, centrifuge at 3000-10000rpm, centrifuge for 10-20min, remove the black precipitate, take the upper layer of brown-yellow clear liquid, which is the aqueous solution of carbon nanodots, in which the surface of the carbon nanodots is partially oxidized , With abundant carbon-oxygen bonds;

[0023] (3) Fully mix the aqueous solution of carbon nanodots with the aqueous solution of polyvinyl alcohol to obtain a mixed solution. In the mixed solution, the mass ratio of carbon nanodots to polyvinyl alcohol is 1:50-1:500, and the mixed solution is 60-90 After drying at ℃, a pure organic long afterglow composite material is obtained.

[0024] In this embodiment, the concentration of the aqueous solution of...

Embodiment 1

[0028] Put a crucible containing 1.6 grams of ethylenediaminetetraacetic acid into a tube furnace, and keep it under a nitrogen atmosphere at 400°C for 4h. Disodium ethylenediaminetetraacetic acid is completely pyrolyzed to obtain a black fluffy solid; the black fluffy solid Dissolved in 80ml of water with the aid of ultrasound, and then centrifuged (9500rpm, 10min) to remove large particles to obtain a brownish-yellow aqueous solution, that is, an aqueous solution of carbon nanodots obtained by purification; a polyvinyl alcohol aqueous solution with a mass fraction of 10wt% was configured, and the concentration of 1ml was 2mg / ml carbon nano-dot water solution and 5ml polyvinyl alcohol aqueous solution are fully mixed to obtain a mixed solution, and the mixed solution is dried at 60°C to obtain a pure organic long-lasting composite material.

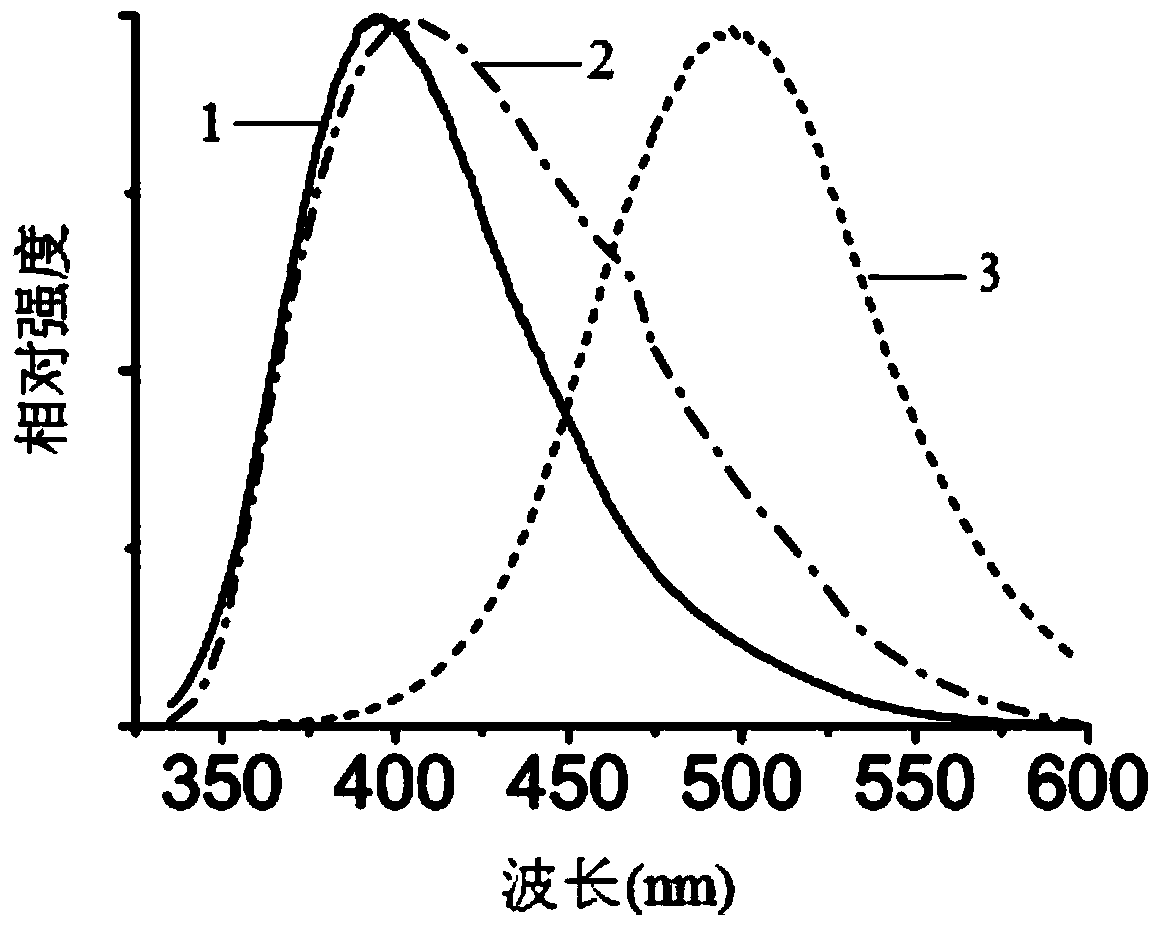

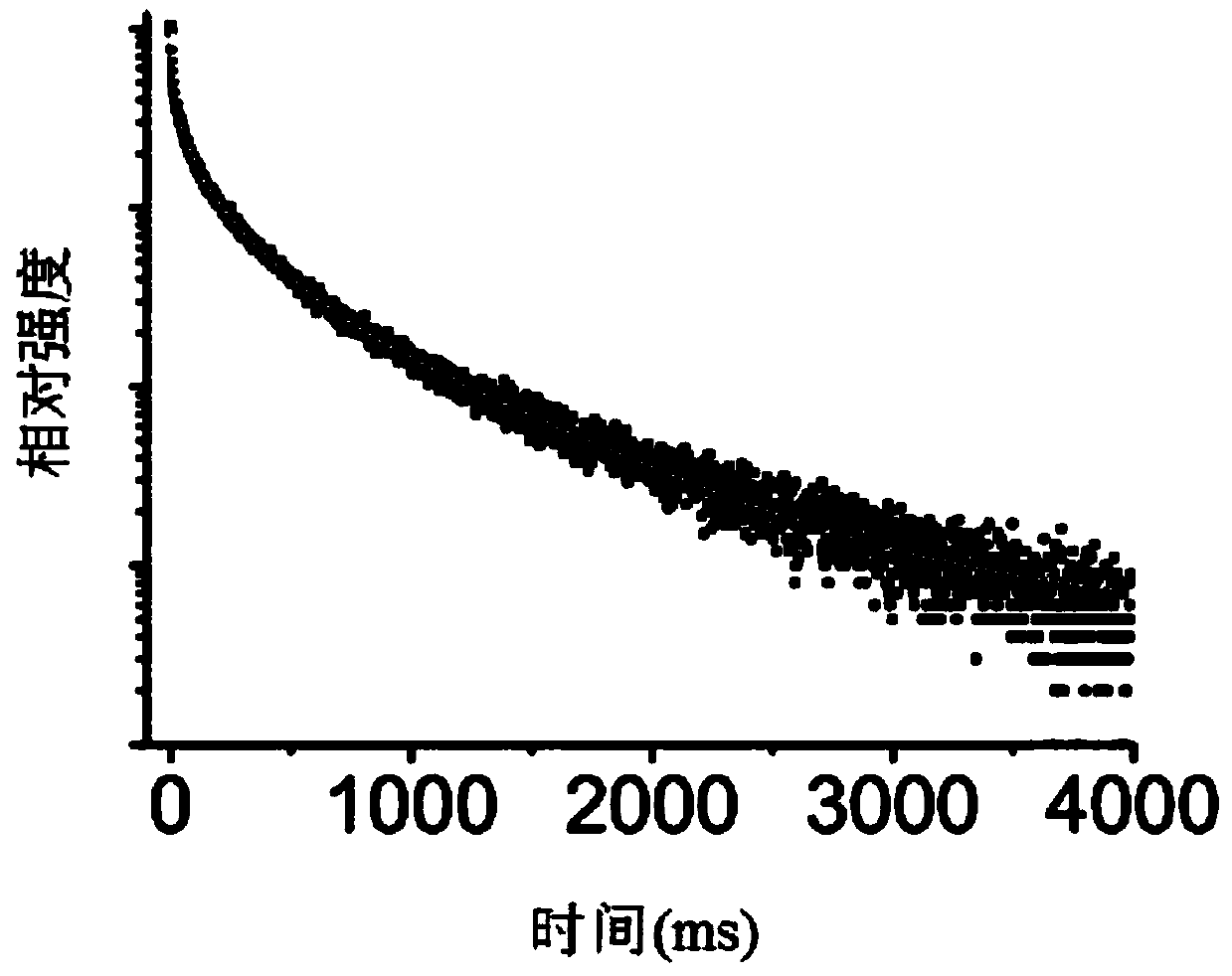

[0029] The composite material prepared in Example 1 was irradiated with an ultraviolet lamp (wavelength: 365nm), and it was observed that ...

Embodiment 2

[0032] Put a crucible containing 1.6 grams of ethylenediaminetetraacetic acid into a tube furnace, and keep it at 200°C for 2h in a nitrogen atmosphere. The disodium ethylenediaminetetraacetic acid is completely pyrolyzed to obtain a black fluffy solid; the black fluffy solid Dissolved in 80ml of water with the aid of ultrasound, and then centrifuged (3000rpm, 20min) to remove large particles to obtain a brown-yellow aqueous solution, that is, an aqueous solution of carbon nanodots obtained by purification; configure a polyvinyl alcohol aqueous solution with a mass fraction of 10wt%, and change the concentration of 1ml to 2mg / ml carbon nanodot aqueous solution and 1ml polyvinyl alcohol aqueous solution are fully mixed to obtain a mixed solution, and the mixed solution is dried at 90° C. to obtain a pure organic long-lasting composite material.

[0033] The composite material prepared in Example 2 was irradiated with an ultraviolet lamp (with a wavelength of 365 nm), and it was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com