Mining spraying material formula and application method

A spraying material and mining technology, which is applied in mining equipment, earthwork drilling, shaft lining, etc., can solve the problems of large auxiliary transportation volume, poor working environment, and many safety hazards, and achieve less auxiliary transportation volume and prevent metal mesh Effect of corrosion and improvement of flexural strength

Inactive Publication Date: 2014-04-02

SHANDONG UNIV OF SCI & TECH +1

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the shortcomings of traditional spraying support technology, such as slow construction speed, poor working environment, large material consumption, large auxiliary transportation volume, and many safety hazards, the present invention provides a mine spraying material formula and application method, which can realize rapid construction , and no dust, no rebound during construction, green and environmentally friendly and material-saving, good flexibility, not easy to crack, even if cracked, it will not hurt people, high safety and reliability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-10

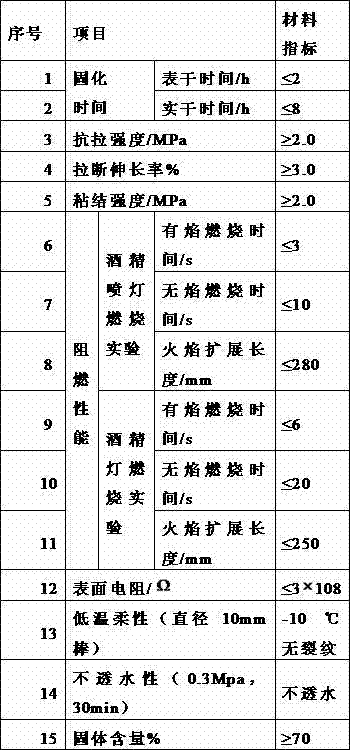

[0091] Example 1-10 Performance index requirements for rapid spraying materials in coal mines

[0092]

Embodiment 1

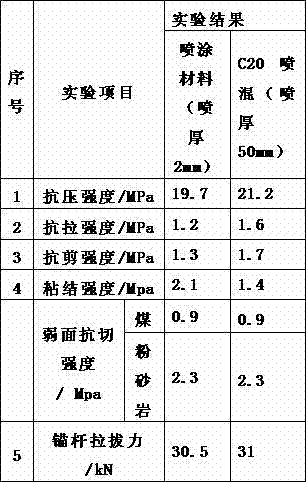

[0093] Example 1 Test results of mechanical properties of spraying materials

[0094]

Embodiment 2

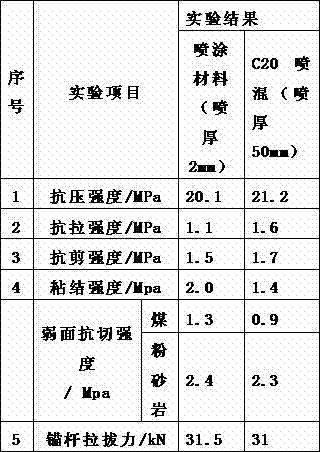

[0095] Example 2 Test results of mechanical properties of spraying materials

[0096]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a mining spraying material formula which is characterized in that: the spraying material comprises a solid material and a liquid material; the solid material comprises the following components: cement, fly ash, a water reducer, an accelerating agent, and fibers; the liquid material comprises at least one of acrylic acid emulsion (pure acrylic acid, styrene acrylate, modified building styrene acrylate, butylbenzene) or 801 glue; the mass ratio of the solid material to the liquid material is 100:3-10; the spraying material formula of the invention is suitable for rapid construction, has no dust or springback during construction, is green, environment-friendly, material-saving, and good in flexibility, is not liable to cracking, does not flake to hurt people even if cracking occurs, and is high in safety and reliability.

Description

technical field [0001] The invention relates to a mineral spraying material formulation and a using method. Background technique [0002] At present, the well-known thin spray for mining is mainly dry spray. Although the spray layer after spraying has a certain supporting effect, its effect is small, the bearing capacity is poor, and the spray layer is easily cracked under pressure, and even slurry appears. The skin peels off in a large area, which brings great hidden dangers to safety production. At the same time, the utilization rate of traditional shotcrete materials is low, the dust is large, and the rebound rate is high, so the construction environment is poor and there is a lot of waste. In addition, the construction speed is slow, and the requirements for auxiliary transportation are large. The shortcomings of these roadway spray protection technologies restrict the development of modern mines. Therefore, a shotcrete material and shotcrete technology with excellent p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04E21D11/10

Inventor 李洪代进刘广成田浩邹方升

Owner SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com