Automobile windowsill outer side sealing strip

A technology for sealing strips and window sills, which is used in sealing devices, engine sealing, vehicle parts, etc., can solve problems such as inconsistency of the body, and achieve the effects of good body coordination, easy mass production, and remarkable appearance effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

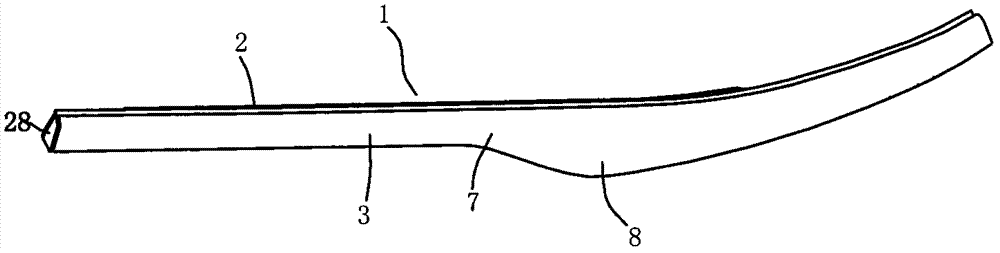

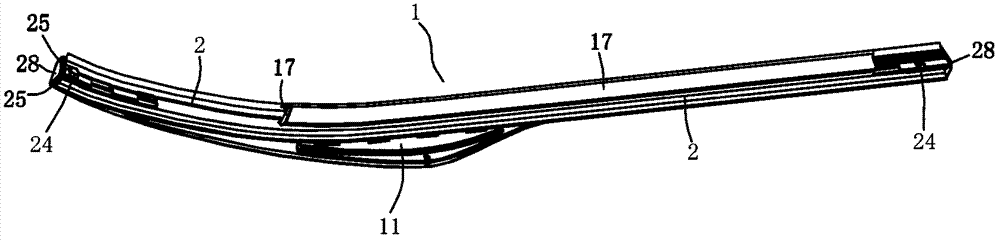

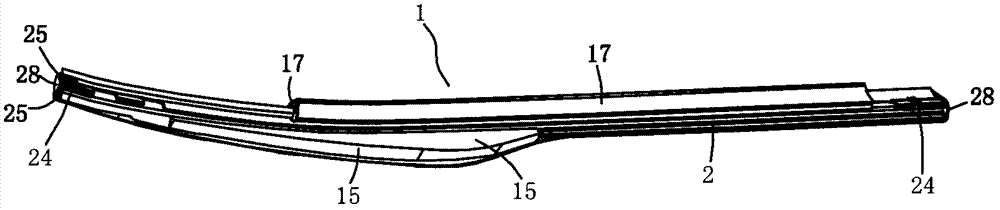

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of automobile window sill outer sealing strip 1 with a streamlined appearance surface includes a body 2 and a bright strip 3, and the body 2 is as Figure 6 As shown, it is an extruded piece formed by continuous extrusion of organic elastic material with the same cross-section and then cut. Its cross-section is as follows Figure 4 As shown, it is an inverted V shape formed by the outer side 4 and the inner side 5 of the car. The V-shaped top of the body 2 is provided with a first protruding lip 6 extending obliquely upward; the body 2 can be made of PVC material, in order to increase its Rigidity, a metal frame 16 can be set in the body 2, the metal frame 16 is a metal thin strip processed by rolling, so that its cross section changes from a straight shape to an inverted V shape and then passes through an extrusion die, and the PVC material is heated The extrusion die is adsorbed on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com