Wood flexible combined machining system based on network control

A compound processing and network control technology, applied in the field of wood processing, can solve the problems of increasing processing cost, affecting processing accuracy and production efficiency, low level of automation and flexible application, and achieving the goal of overcoming poor operability and improving processing quality and precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

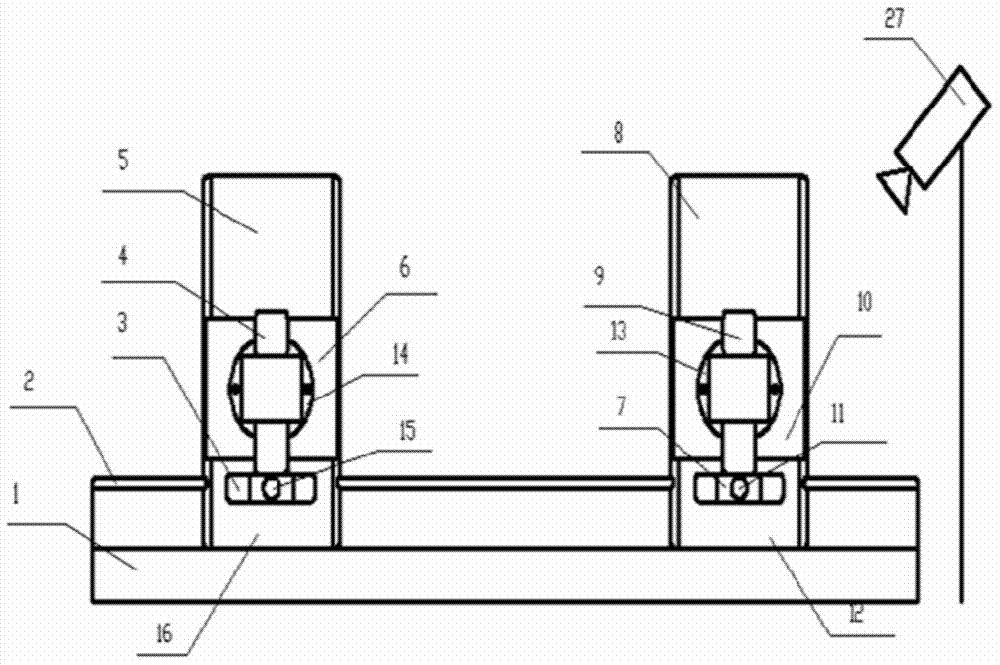

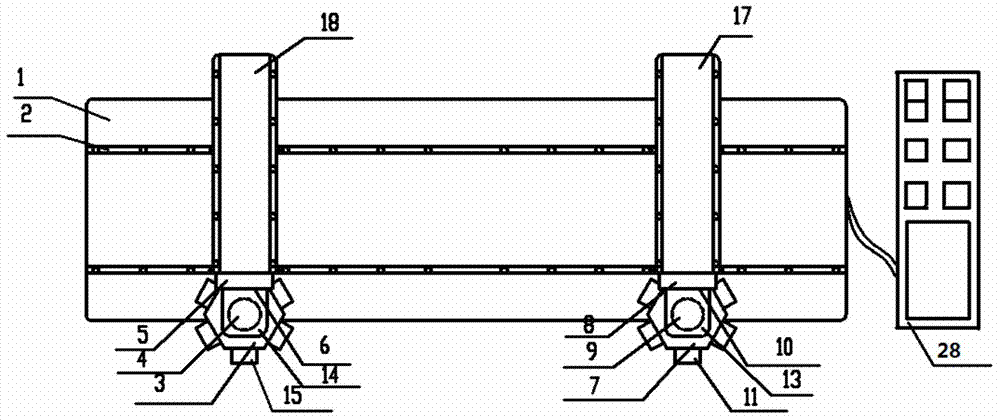

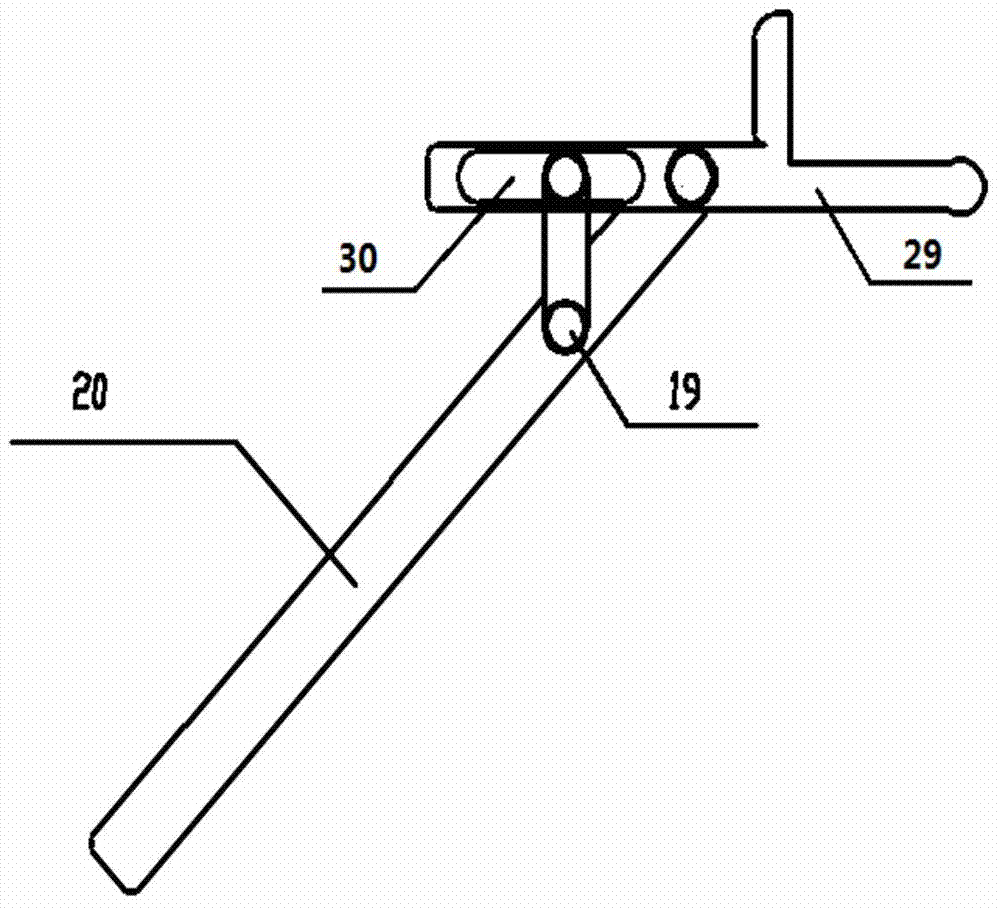

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a wood flexible compound processing system based on network control includes multiple sets of wood flexible compound processing equipment, visual sensors and network control system.

[0026] The wood flexible composite processing equipment includes a processing machine tool, a numerical control system and auxiliary components; the processing machine tool includes a bed 1, a left / right moving column, a left / right spindle, and a left / right turret. Set the direction parallel to the guide rail 2 as the X-axis direction, the direction parallel to the moving column as the Z-axis direction, and the direction perpendicular to the moving column and perpendicular to the X-axis direction as the Y-axis direction. Wherein, the bed 1 is provided with a guide rail 2, the left moving column 5 is vertically installed on the guide rail 2, and the left horizontal axis motor 16 is used to drive the left moving column 5 so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com