Method for preparing lithium tantalate chip for pyroelectricity detector

A technology of lithium tantalate and lithium tantalate, applied in the field of pyroelectric detectors, can solve problems such as difficult roughness and affecting device performance, and achieve the effects of less equipment investment, simple process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

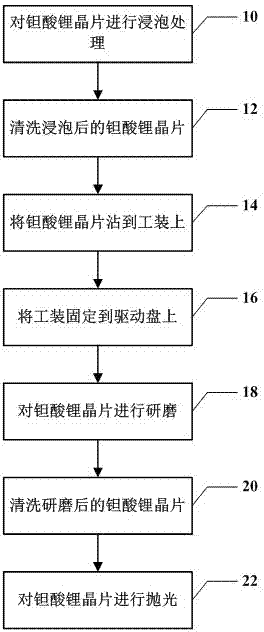

[0018] The specific steps of the method for preparing a lithium tantalate wafer for pyroelectric detectors according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] In one embodiment of the present invention, a kind of method that prepares the lithium tantalate wafer that is used for pyroelectric detector is as figure 1 shown.

[0020] In this embodiment, in step 10, a lithium tantalate wafer with a predetermined thickness is firstly obtained, and the lithium tantalate wafer with a predetermined thickness is placed in a soaking solution for soaking treatment.

[0021] Here, the "predetermined thickness" may be a predetermined thickness according to actual needs. For example, in one embodiment, the predetermined thickness may be 100 microns.

[0022] In one embodiment, step 10 may include soaking the lithium tantalate wafer in ethanol solution and acetone solution respectively. For example, ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com