Automatic three-gear stepless speed change main transmission system

A technology of main transmission system and stepless speed change, which is applied in the direction of automatic lathes/semi-automatic lathes, driving devices, turning equipment, etc. It can solve the problems of limited speed regulation range, inability to realize high-speed cutting, complex mechanical speed change structure, etc., and achieve speed regulation Wide range, simple structure, and the effect of overcoming vibration and noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

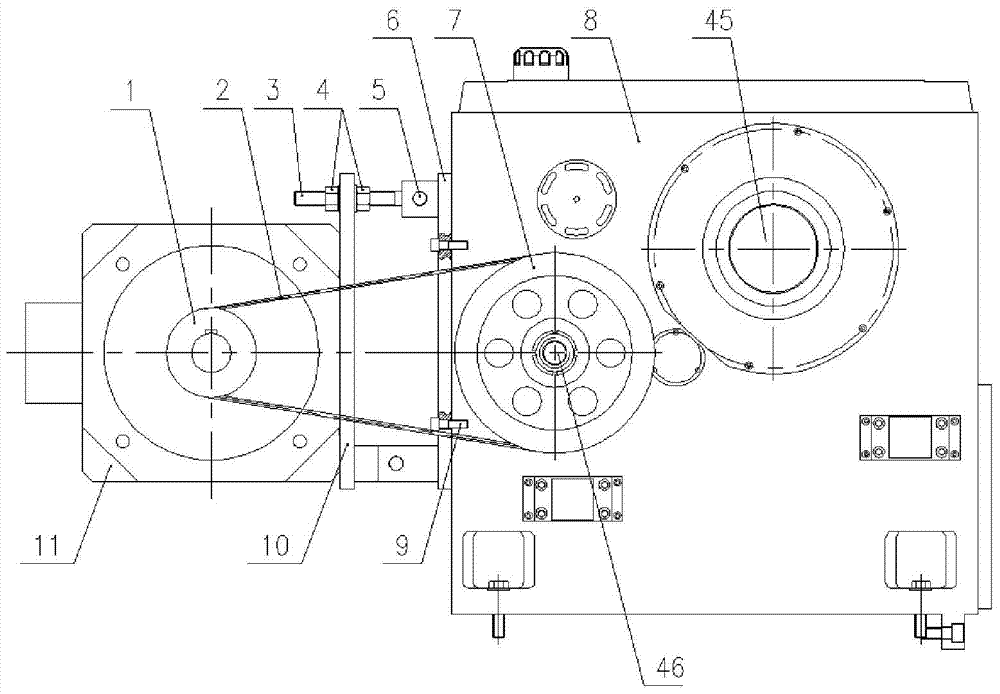

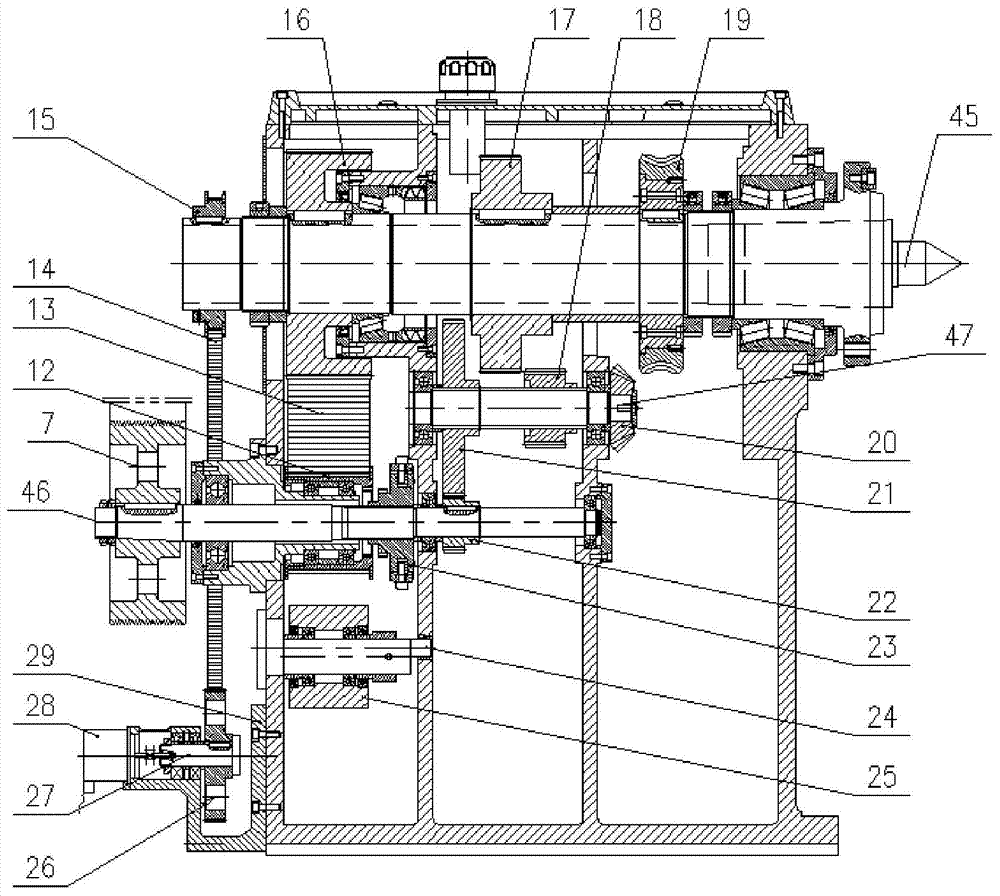

[0020] Such as Figures 1 to 6 As shown, the described a kind of automatic three-speed continuously variable transmission main transmission system is characterized in that it includes a motor device, a main transmission mechanism, a worm gear transmission mechanism and a hydraulic shift mechanism, and the described motor device includes a main shaft servo motor 11, The main shaft servo motor 11 is installed on the main shaft housing 8 through the motor base plate 6, and the power output shaft of the main shaft servo motor 11 is provided with an active ribbed pulley 1, and the active ribbed pulley 1 is connected to the main transmission mechanism through the ribbed belt 2. The driven ribbed pulley 7 at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com