Machining method for effectively improving quality of large forging

A processing method and technology for large forgings, applied in the field of smelting and forging, can solve the problems of waste of ingot materials, inclusion defects of large ingot nozzles, etc., and achieve the effect of reducing forging procedures, reducing processing costs and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The purpose of the present invention is to provide a practical and efficient forging processing method, which can effectively improve the processing quality of large forgings. The steps are as follows:

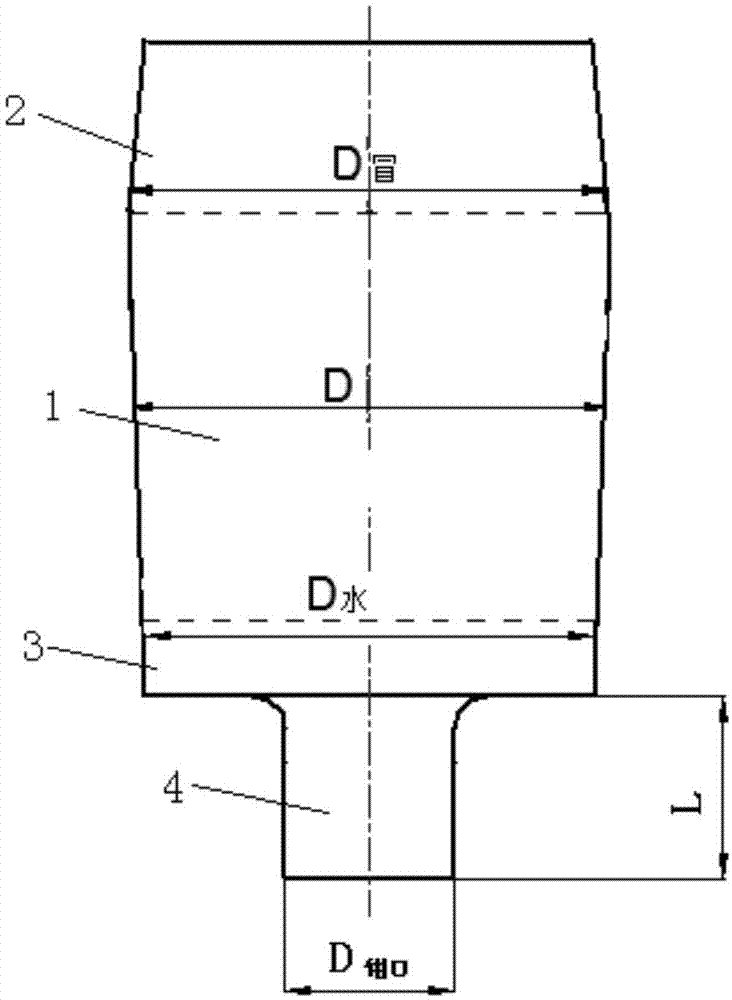

[0026] 1) First press figure 1 Ingot shown. According to the characteristics of the casting, after the casting is completed, a riser 2 will be left on the top of the ingot body 1, and a nozzle 3 will be left at the bottom. Note that the average diameter of the ingot body is D, and the average diameter of the riser is D 冒 , the average nozzle diameter is D 水 , generally speaking, D 冒 ≥D≥D 水 .

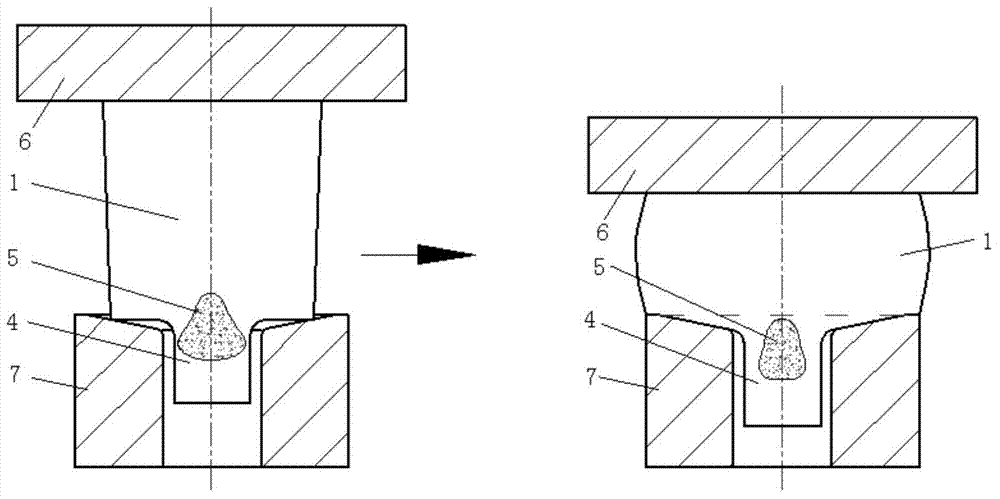

[0027] In the method of the present invention, in order to reduce material waste as much as possible and achieve better forging effect, a nozzle manipulator or a nozzle jaw 4 that can be clamped by a forging sleeve is designed at the beginning of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com