Gravity loading mechanism of high pressure extrusion mill

A technology of gravity loading and grinding, applied in grain processing and other directions, can solve the problems of strong horizontal vibration and torsional vibration of the main shaft, large impact load, and retraction of movable rollers, so as to avoid response hysteresis, ensure mechanical strength, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described below in conjunction with specific embodiments.

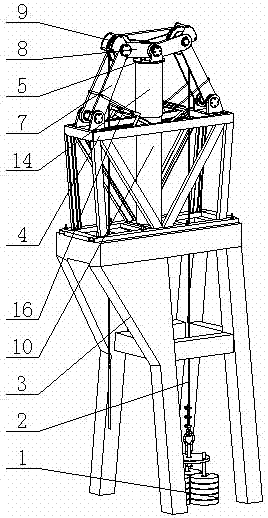

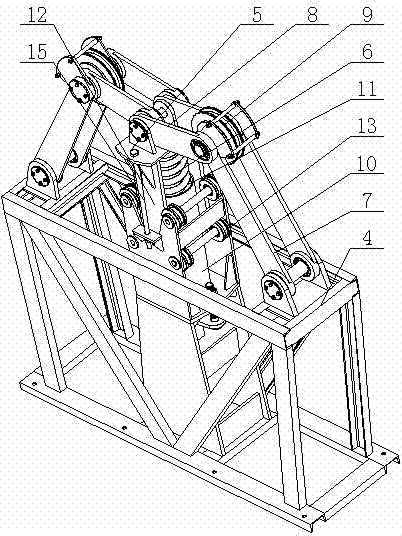

[0026] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of a gravity loading mechanism of a high-pressure extrusion mill according to the present invention. The gravity loading mechanism of a high-pressure extrusion mill according to the present invention includes: a loading weight 1 and a steel cable 2 connected to the loading weight 1; a steel cable 2 for supporting the loading A bracket 3 in which the weight 1 is suspended in the air; a buffer device arranged on the top of the bracket 3, the steel cable 2 bypasses the buffer device to buffer the height change of the loading weight 1 caused when the roller retreats. Specifically, preferably, the buffer device includes a fixed base 4 and a movable support part 5, the steel cable 2 bypasses the support part 5, and an elastic body 6 is arranged between the support part 5 and the base 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com