Device for preparing high-viscosity polyvinyl alcohol resin solution

A polyvinyl alcohol resin, high viscosity technology, used in mixers with rotating stirring devices, dissolving, dissolving and other directions, can solve the problem of "holding the shaft" concentration, unevenness and other problems, achieve uniform heating temperature, reduce product consumption, prevent The effect of high pressure gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

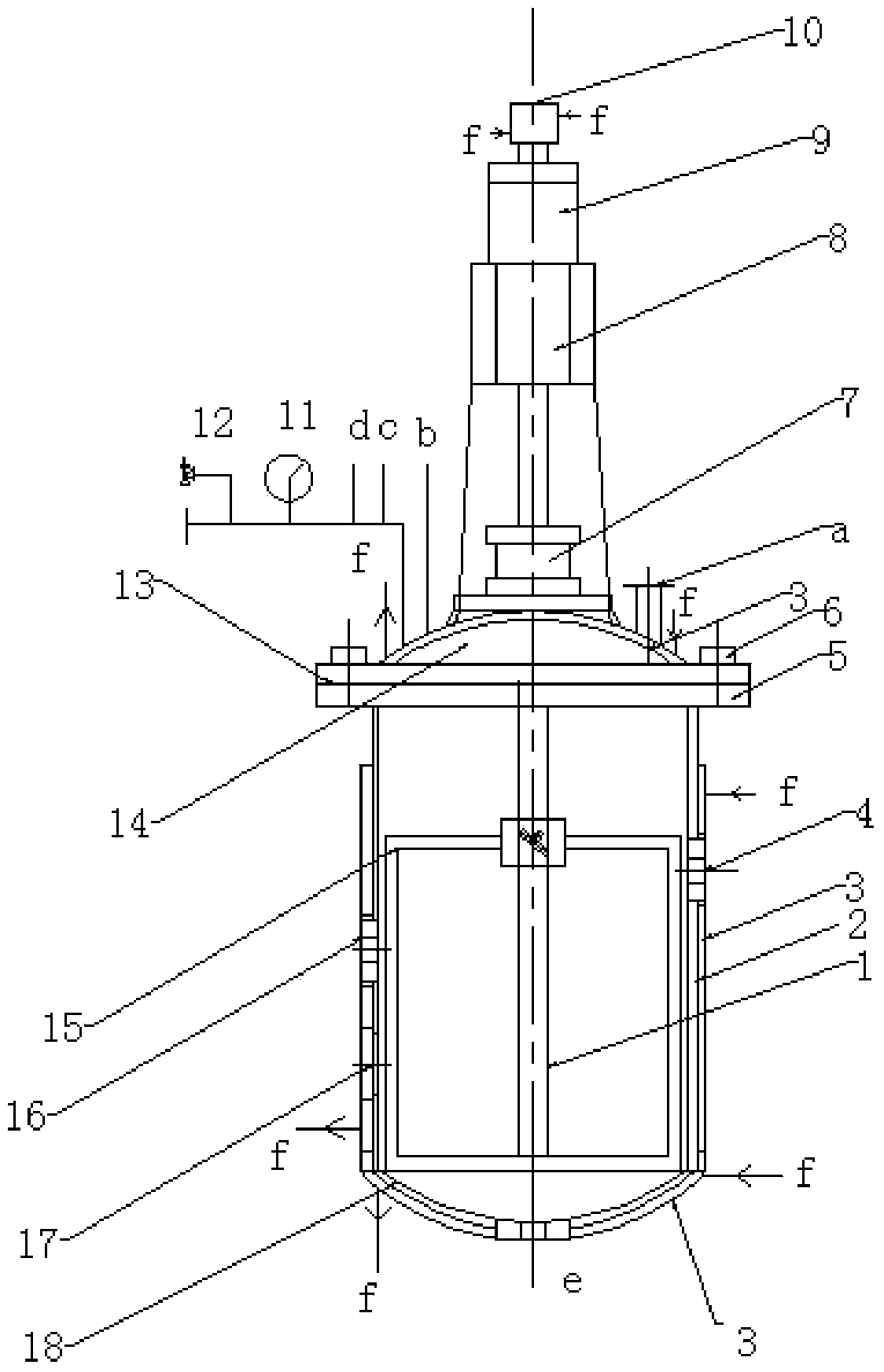

[0024] Such as figure 1 As shown, the device for preparing a high-viscosity polyvinyl alcohol resin solution in this embodiment includes a cylinder unit, a stirring unit and an instrument control detection unit;

[0025] The cylinder unit is a pressure vessel in which the upper end of a cylinder 2 is connected with the upper head 14 through the equipment flange 5, and the lower end is sealed by the lower head 18; a and water inlet b; the bottom of the lower head 18 is provided with a discharge port e; on the side wall of the cylinder 2, the outer surface of the upper head 14 and the outer surface of the lower head 18, a heating medium is respectively provided Jacket 3 for mass circulation flow;

[0026] The stirring unit is connected by the motor 9 above the cylinder unit through the reducer 8 to the hollow stirring shaft 1 extending into the cylinder 2 to drive the agitator 15 inside the cylinder 2 to rotate;

[0027] The connection between the hollow stirring shaft 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com