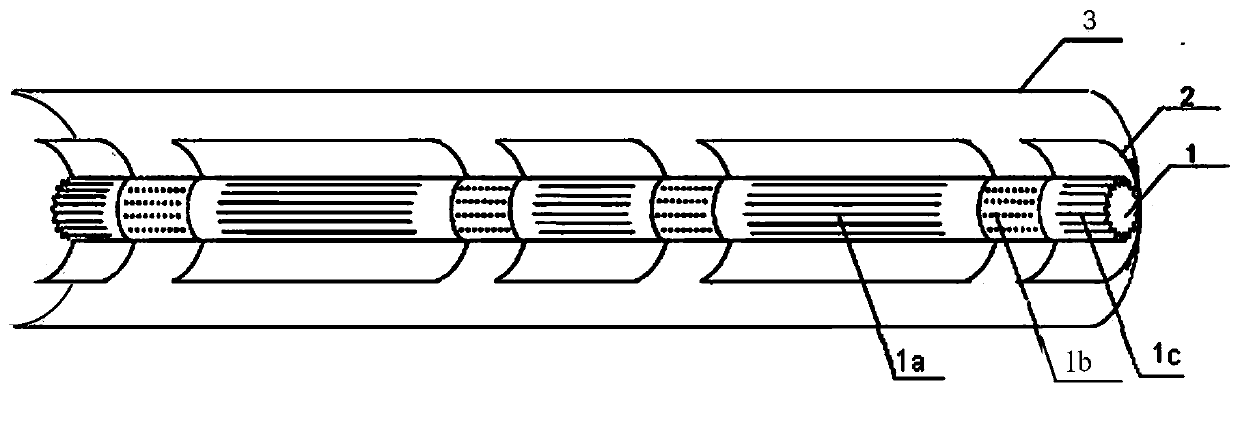

Preparation method for coffee and natural plant powder composite particles and application of coffee and natural plant powder composite particles to cigarette filters

A technology of natural plants and composite particles, used in applications, e-liquid filters, tobacco, etc., can solve problems such as lack, tongue residue, roughness, etc., to improve aroma quality and coordination, reduce impurities and irritation, improve Effects of Intrinsic Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

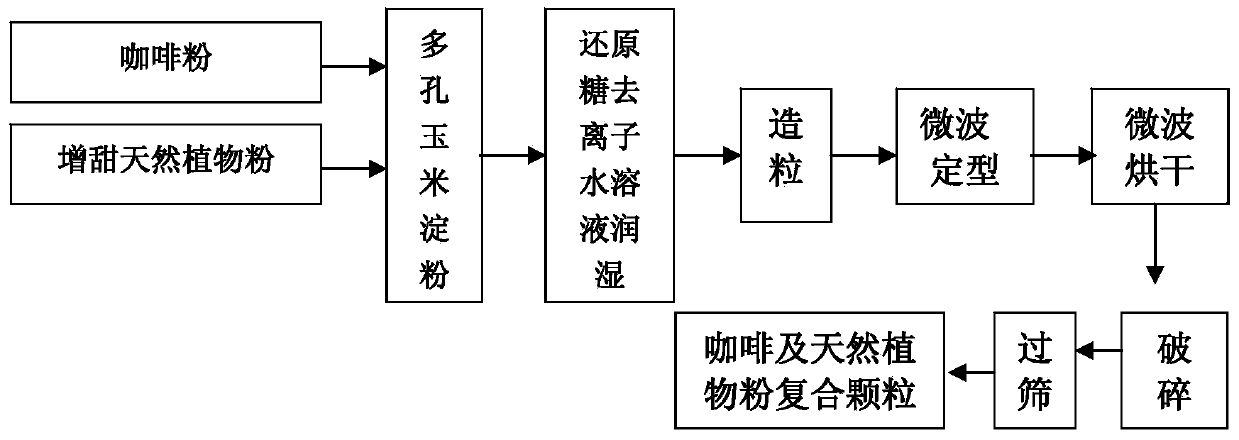

Method used

Image

Examples

Embodiment 1

[0034] Weigh 300g of coffee powder, 50g of sweetened natural plant powder (25g of licorice powder, 10g of ebony powder, 15g of stevia powder), add to 1Kg of porous cornstarch, and mix well. Take 1000mL of 20% glucose deionized water solution and spray evenly into the above mixed powder to make the powder wet. The wetted powder is passed through a 20-mesh sieve by extrusion granulation to obtain particles smaller than 20 mesh. Put the above particles into a microwave oven, and treat the particles intermittently at a microwave power density of 20 kW / m2 for a total of 6 minutes in a non-dehumidifying state for gelation and setting; The microwave power density is intermittently processed for a total of 9 minutes to dry coffee and natural plant powder composite particles. The above microwave treatment should control the temperature not to exceed 100°C. The obtained granules are respectively passed through standard sieves of 20 mesh and 40 mesh to obtain composite granules of coffe...

Embodiment 2

[0036] Weigh 200g of coffee powder, 20g of sweetened natural plant powder (20g of ebony powder), add to 1Kg of porous cornstarch, and mix well. Take 1000mL of 10% fructose deionized water solution and spray evenly into the above mixed powder to make the powder wet. The wetted powder is passed through a 20-mesh sieve by extrusion granulation to obtain particles smaller than 20 mesh. Put the above particles into a microwave oven, and treat the particles intermittently at a microwave power density of 20 kW / m2 for a total of 6 minutes in a non-dehumidifying state for gelation and setting; The microwave power density is used to treat the granules intermittently for a total of 8 minutes to dry coffee and natural plant powder composite granules. The above microwave treatment should control the temperature not to exceed 100°C. The obtained granules are respectively passed through standard sieves of 20 mesh and 40 mesh to obtain composite granules of coffee and natural plant powder of...

Embodiment 3

[0038] Weigh 100g of coffee powder, 10g of sweetened natural plant powder (licorice powder 10g), add to 1Kg of porous cornstarch, and mix well. Take 900mL of 5% maltose deionized aqueous solution and spray evenly into the above mixed powder to make the powder wet. The wetted powder is passed through a 20-mesh sieve by extrusion granulation to obtain particles smaller than 20 mesh. Put the above particles into a microwave oven, and treat the particles intermittently at a microwave power density of 20 kW / m2 for a total of 5 minutes in a non-dehumidifying state for gelation and setting; The microwave power density is used to treat the granules intermittently for a total of 7 minutes to dry coffee and natural plant powder composite granules. The above microwave treatment should control the temperature not to exceed 100°C. The obtained granules are respectively passed through standard sieves of 20 mesh and 40 mesh to obtain composite granules of coffee and natural plant powder of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com