Motor stator and permanent magnet rotating electric machine

A motor and stator technology, applied in the field of permanent magnet rotating electrical machines, can solve the problems of high density requirements, reduced insulation distance, reduced insulation distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

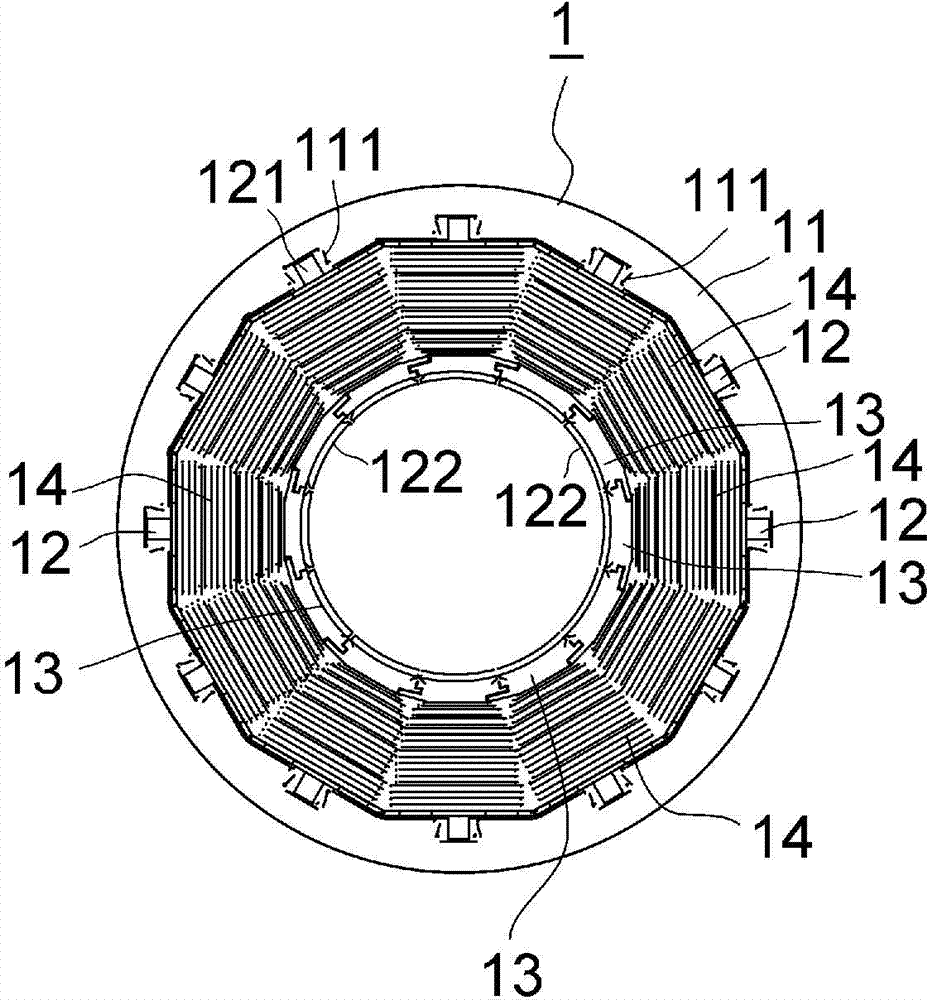

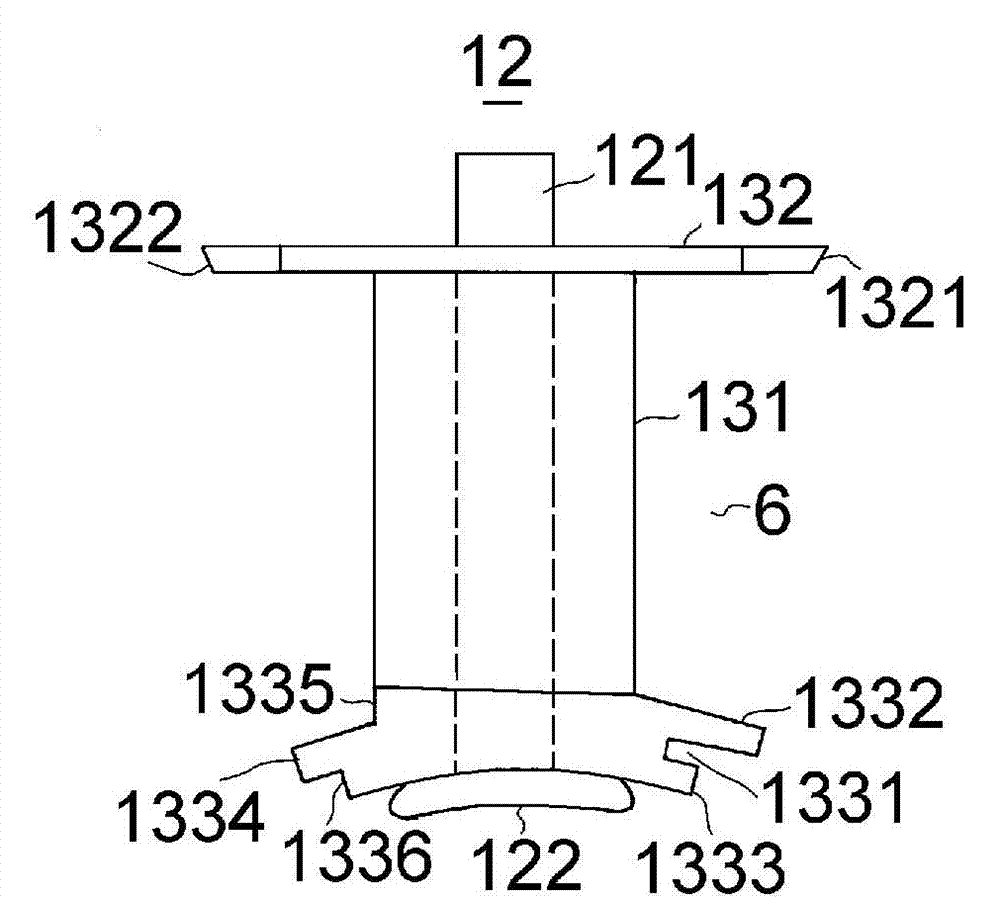

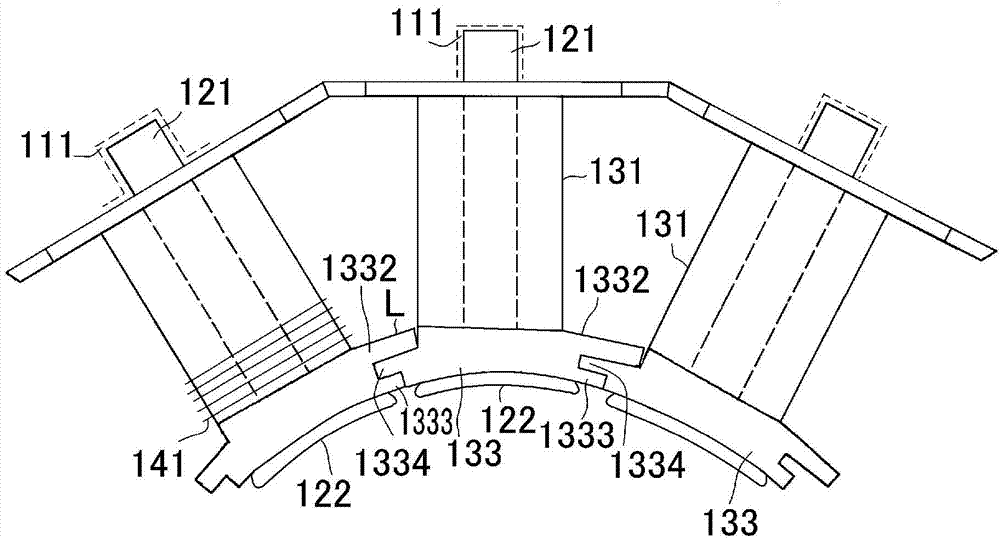

[0057] figure 1 It is a structural diagram showing the stator structure of the main components included in the stator of the motor of the present invention, figure 2 Is to figure 1 A part (single) of the coil bobbin is enlarged to show the structure of the coil bobbin, image 3 It is a configuration diagram that explains the combination of adjacent coil bobbins by combining a plurality of coil bobbins, Figure 4 with Figure 5 It is an exploded perspective view showing the main parts and assembly structure of the yoke core, tooth core, and coil bobbin of the stator of the present invention.

[0058] In these figures, 1 denotes a stator (stator) that interacts with a rotor (not shown) of a motor to generate rotational momentum. The stator includes a cylindrical yoke core (yoke core) 11 and a yoke core disposed thereon. The parts described later inside the cylinder. The stator further includes a plurality of T-shaped tooth cores 12 composed of split cores, a plurality of coil bobbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com