Extrusion press

A technology for extruders and extrusion barrels, applied in the field of extrusion machines that seek multi-function and shorten idle time, can solve the problems of increasing the stripping force of extrusion barrels, consuming useless energy, and poor energy efficiency. Achieving increased peeling force, easy design, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

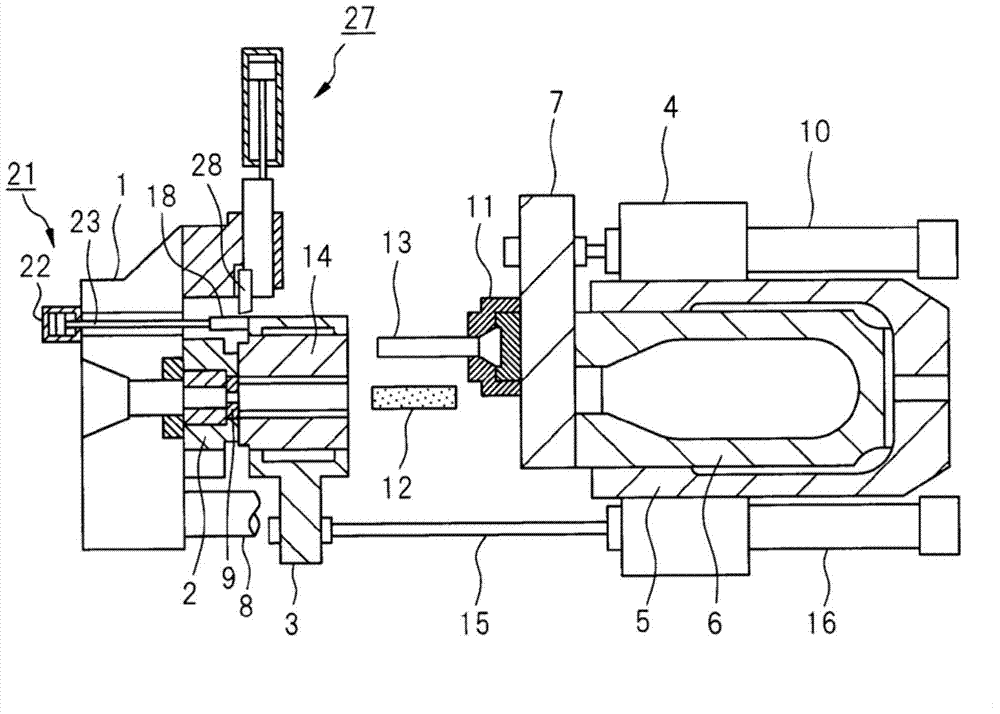

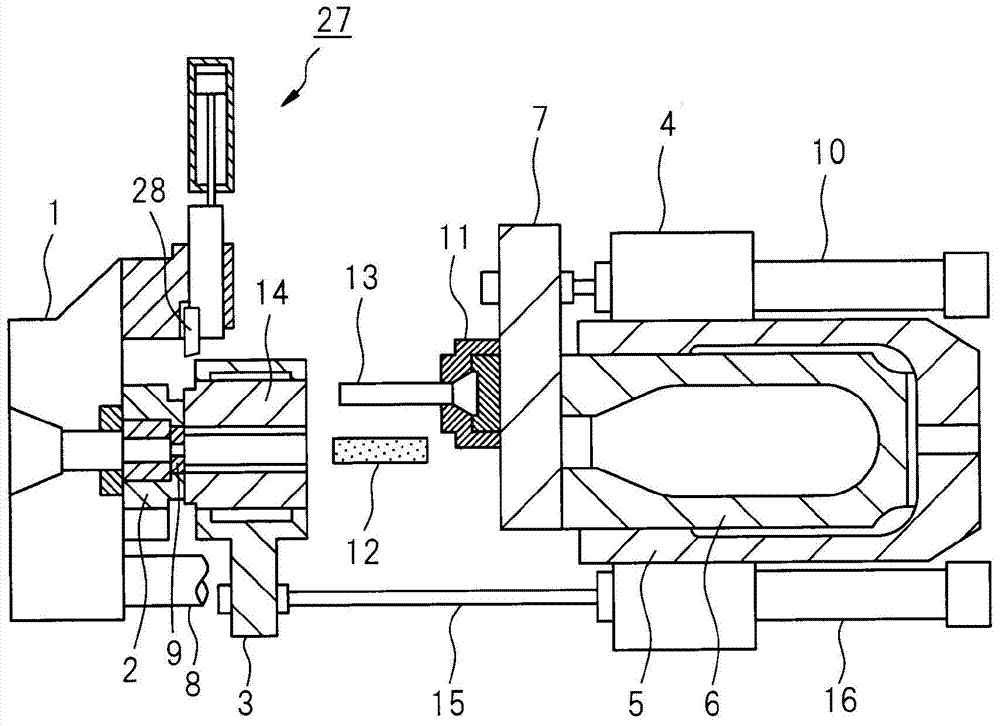

[0027] Below, according to figure 1 The present invention will be described in detail. figure 1 It shows an embodiment of the extrusion machine of the present invention, 1 is an end table, 2 is a die slide device equipped with a die 9 for product extrusion, and 3 is an extrusion for storing an extrusion material (billet) 12 The cylinder 14 holds the extrusion cylinder holder, 4 is the main cylinder shell, 5 is the main cylinder, 6 is the main piston, 7 is the main crosshead integrally installed at the front end of the main piston 6, and 10 is the main crosshead for the main cylinder. The movement of 13, the side cylinder that is located on the left and right horizontal outer parts of master cylinder 5.

[0028] On the front end portion of the main crosshead 7 , a squeeze bar slider 11 is slidably attached in a vertical or horizontal direction perpendicular to an axis direction which is the forward and backward travel direction of the main crosshead 7 . An extruding rod 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com