Duct unit and cable duct

A pipeline and cable technology, applied in the field of cable pipeline, can solve the problems of difficult maintenance and complicated operation of installing cables, and achieve the effect of high maintenance efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

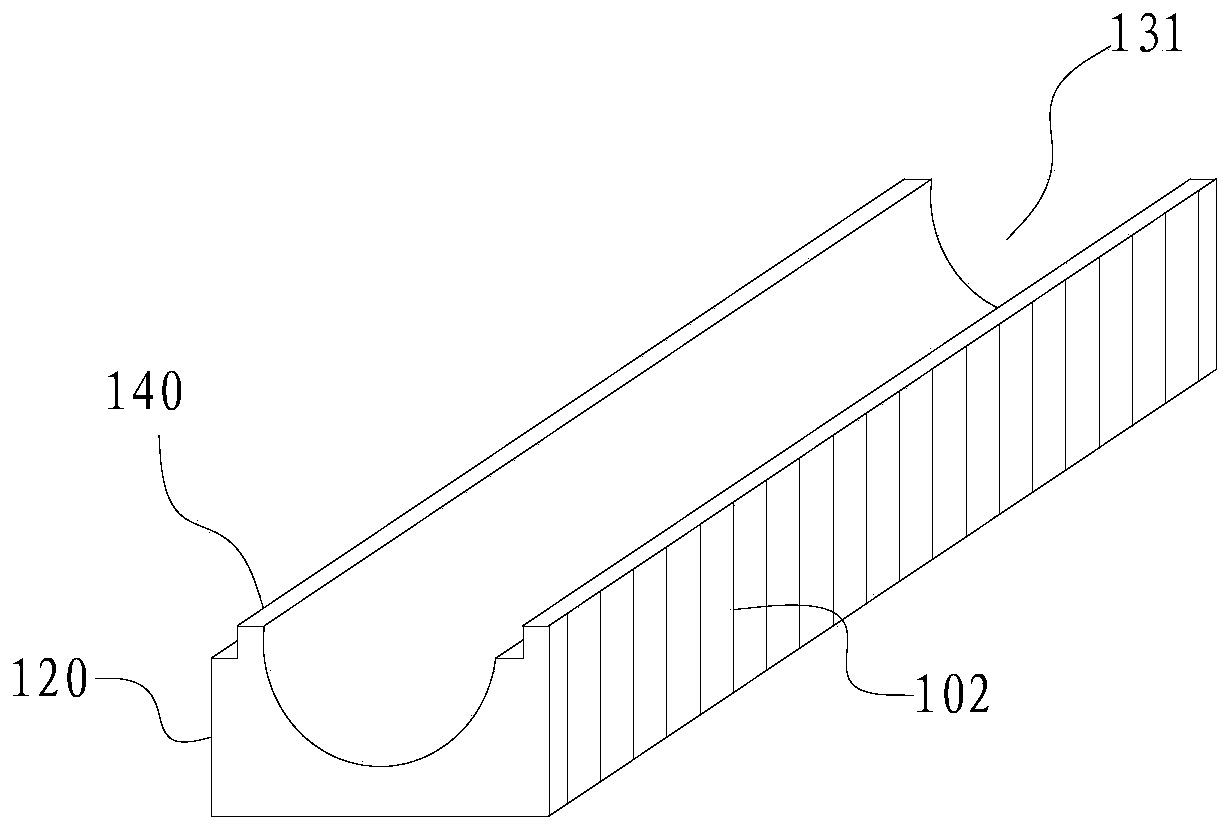

[0061] see Figure 1 ~ Figure 3 , this embodiment discloses a pipeline unit 100, the pipeline unit 100 includes a grooved body 120 and a grooved cover 110, the grooved cover 110 is fastened on the grooved body 120, the A slot cavity 130 is formed between the slot-shaped main body 120 and the slot-shaped cover body 110 , and the slot cavity 130 extends along the length direction of the pipeline unit 100 for accommodating cables.

[0062] In this embodiment, the grooved main body 120 and the grooved cover 110 are respectively provided with a fastening surface, and the fastening surfaces of the grooved main body 120 and the grooved cover 110 are arranged correspondingly. , for fastening together; there are respectively an opening groove 131 on the fastening surface, and the groove-shaped main body 120 is set correspondingly to the opening groove 131 of the groove-shaped cover 110 for buckling together One cavity 130 .

[0063] The trough-shaped body 120 and the trough-shaped co...

Embodiment 2

[0071] see Figure 4 , this embodiment discloses a pipeline unit 100, which is another preferred solution for the fastening method between the grooved body 120 and the grooved cover 110 on the basis of Embodiment 1, In addition, other technical solutions disclosed in Embodiment 1 also belong to this embodiment, and will not be described again here.

[0072] Specifically, different from the stepped structure 140 in the first embodiment, a mortise and tenon structure 170 is provided on the edge of the opening groove 131 . see Figure 4 , the two notch sides of the groove-shaped main body 120 are provided with protruding tenon structures, and the two notch sides of the groove-shaped cover body 110 are provided with concave mortise structures, and the mortise structures are consistent with the Compatible with the mortise and tenon structure.

[0073] The trough-shaped cover 110 is buckled on the trough-shaped main body 120 , and the tenon structure is inserted and locked. Used...

Embodiment 3

[0077] see Figure 5 ~ Figure 6 , this embodiment discloses a pipeline unit 100, which is a further improvement on the basis of Embodiment 1. The technical solution disclosed in Embodiment 1 also belongs to this embodiment, and the technical solutions disclosed in the embodiment are no longer Repeat description.

[0078] In a specific operation, in order to simultaneously lay out multiple parallel cables in the lateral direction, a plurality of parallel groove cavities 130 may be arranged laterally in the pipe unit 100 as required.

[0079] Specifically, the pipeline unit 100 includes a grooved body 120 and a grooved cover 110, the grooved body 120 and the grooved cover 110 are respectively provided with a fastening surface, and the grooved body 120 and the fastening surface of the trough-shaped cover 110 are arranged correspondingly for fastening together; there are more than one opening groove 131 on the fastening surface respectively, and the trough-shaped main body 120 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com