Polyvinylidene fluoride-hexafluoropropylene-based gel polymer electrolyte as well as preparation method and application thereof

A hexafluoropropylene-based gel, polyvinylidene fluoride technology, applied in capacitor electrolytes/absorbents, electrolytic capacitors, circuits, etc., can solve the problems of accelerated gas, gas leakage, safety hazards, etc., to overcome safety hazards and environmental problems Pollution, excellent electrochemical performance, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

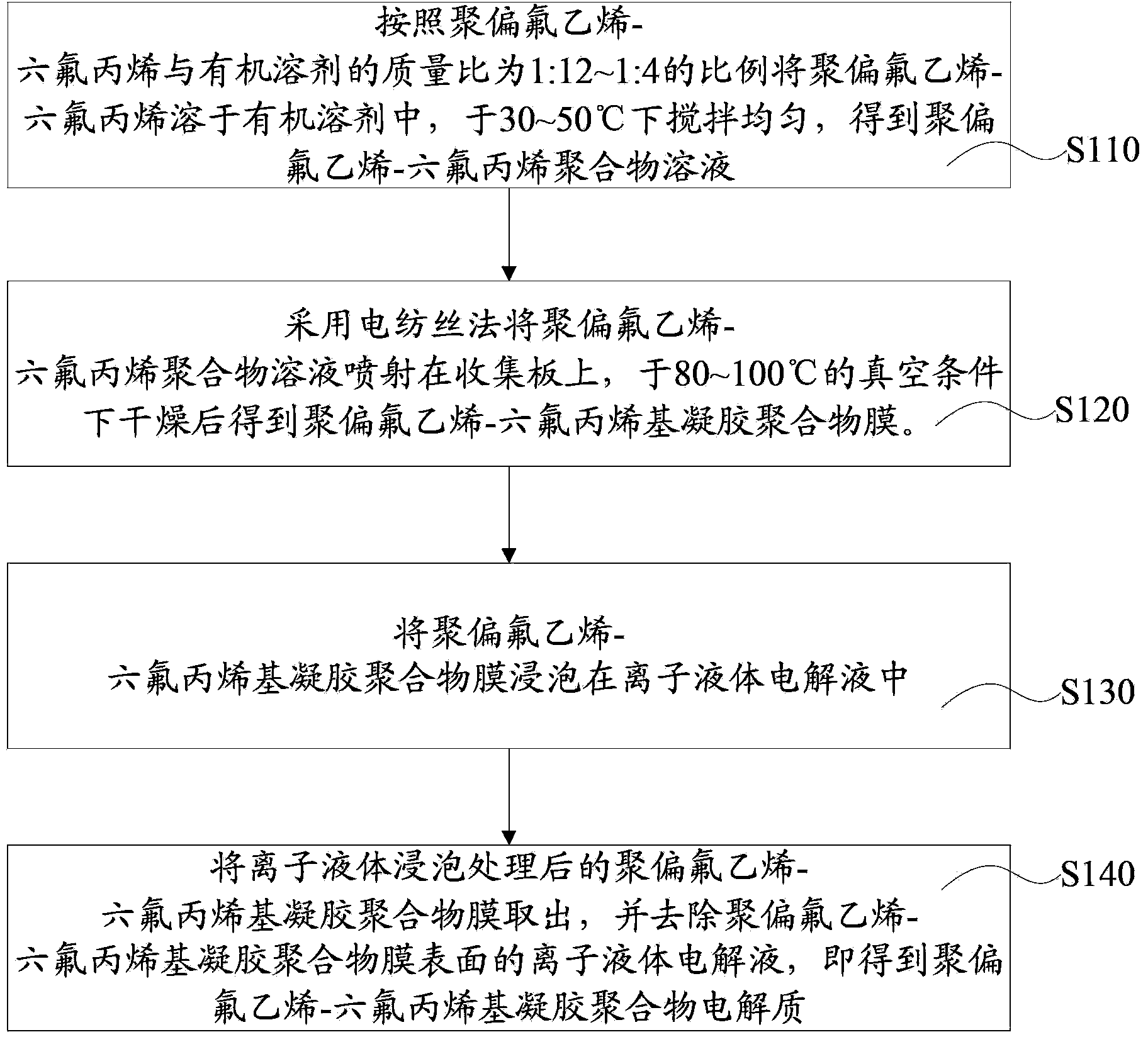

[0026] In addition, this embodiment also provides a method for preparing polyvinylidene fluoride-hexafluoropropylene gel polymer electrolyte, such as figure 1 shown, including the following steps:

[0027] Step S110, dissolving polyvinylidene fluoride-hexafluoropropylene in the organic solvent according to the mass ratio of polyvinylidene fluoride-hexafluoropropylene to organic solvent is 1:12~1:4, stirring at 30~50°C Uniformly, obtain polyvinylidene fluoride-hexafluoropropylene polymer solution.

[0028] Among them, the molecular weight of polyvinylidene fluoride-hexafluoropropylene is 300,000 to 800,000.

[0029] The organic solvent is N-methylpyrrolidone, N,N-dimethylformamide, acetonitrile or ethanol.

[0030] Step S120, spraying the polyvinylidene fluoride-hexafluoropropylene polymer solution on the collecting plate by electrospinning, drying under vacuum conditions at 80-100°C to obtain polyvinylidene fluoride-hexafluoropropylene-based gel polymerization physical film...

Embodiment 1

[0045] Dissolve 10 g of polyvinylidene fluoride-hexafluoropropylene with a molecular weight of 500,000 in 90 g of N-methylpyrrolidone, and stir evenly at 40° C. to obtain a polyvinylidene fluoride-hexafluoropropylene solution.

[0046] Polyvinylidene fluoride-hexafluoropropylene polymer solution is sprayed on the collecting plate by electrospinning method, and the thickness of the polyvinylidene fluoride-hexafluoropropylene gel polymer film deposited on the collecting plate is controlled to be 0.20mm, and then The polyvinylidene fluoride-hexafluoropropylene gel polymer film was cut into discs with a diameter of 12 mm, and the obtained discs were dried at 100° C. under a vacuum condition of 0.01 MPa for 36 h. Among them, the model of the electrospinning machine used is BGG4-21, and the working parameters of the electrospinning machine are: the distance between the spinneret and the collecting plate is 15cm, the spinning voltage is 12KV, polyvinylidene fluoride-hexafluoropropylen...

Embodiment 2

[0049] Dissolve 10 g of polyvinylidene fluoride-hexafluoropropylene with a molecular weight of 300,000 in 40 g of acetonitrile, and stir evenly at 30° C. to obtain a polyvinylidene fluoride-hexafluoropropylene solution.

[0050] Polyvinylidene fluoride-hexafluoropropylene polymer solution is sprayed on the collecting plate by electrospinning method, and the thickness of the polyvinylidene fluoride-hexafluoropropylene gel polymer film deposited on the collecting plate is controlled to be 0.10mm, and then The polyvinylidene fluoride-hexafluoropropylene gel polymer film was cut into discs with a diameter of 12 mm, and the obtained discs were dried at 80° C. under a vacuum condition of 0.01 MPa for 12 h. Among them, the model of the electrospinning machine used is BGG4-21, and the working parameters of the electrospinning machine are: the distance between the spinneret and the collecting plate is 15cm, the spinning voltage is 12KV, polyvinylidene fluoride-hexafluoropropylene The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com