Battery pressure test method and test system based on explosion-proof mathematical model

A mathematical model and pressure test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of high test accuracy and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

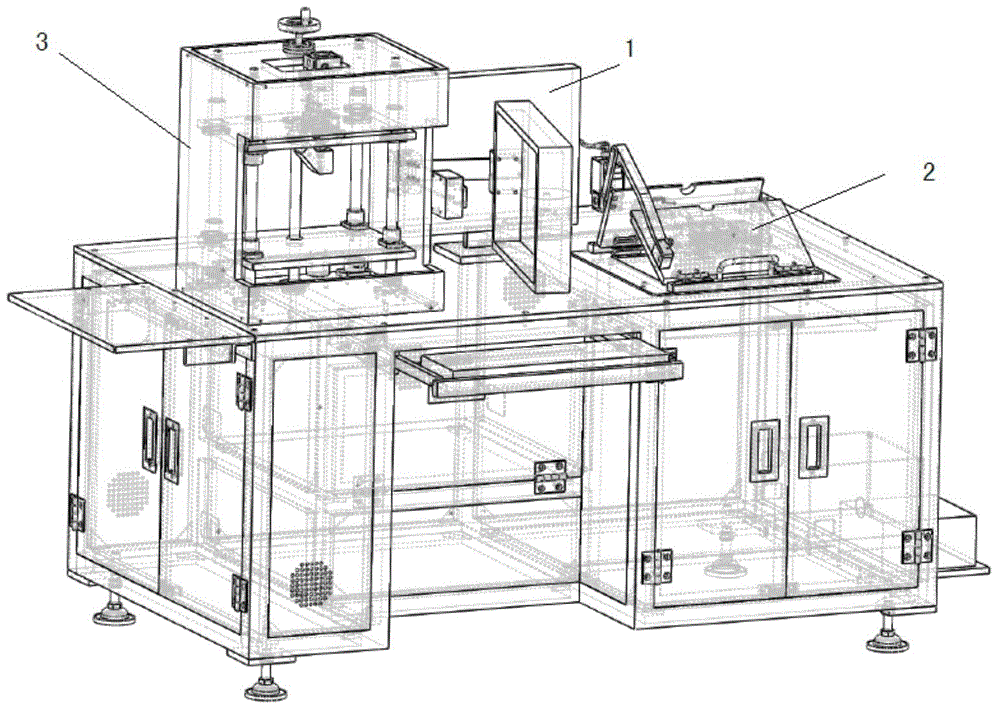

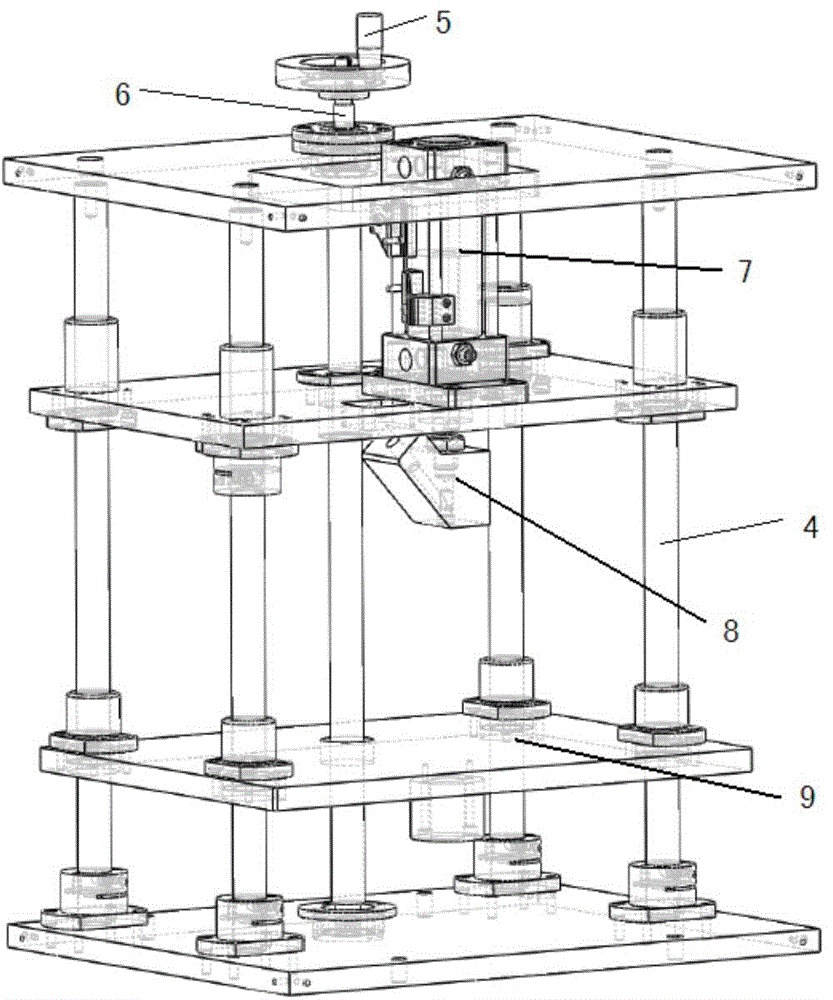

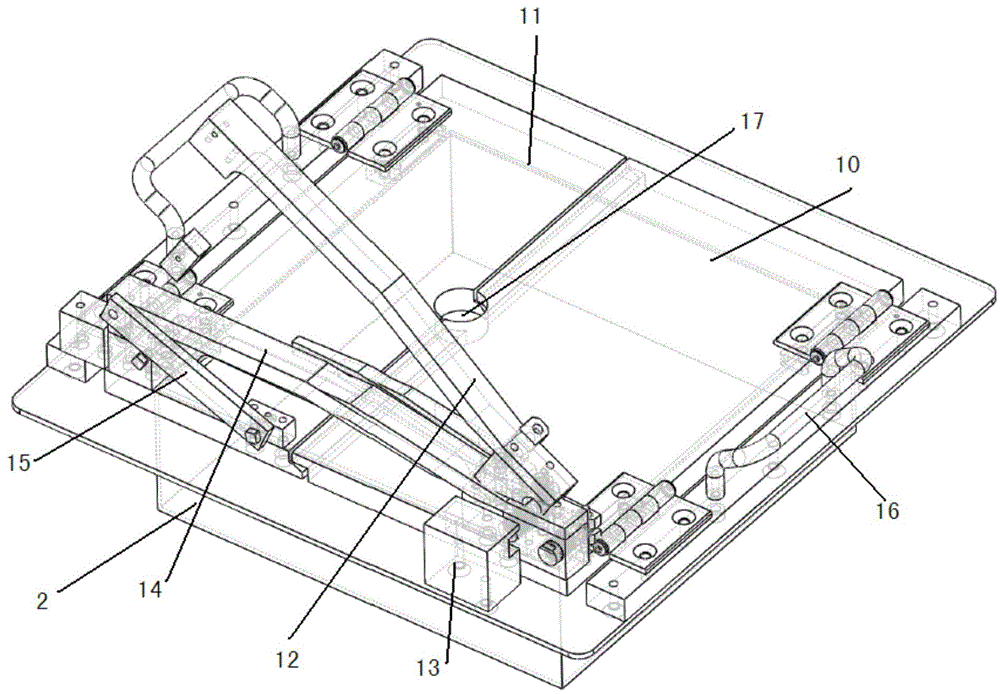

[0042] see Figure 1 ~ Figure 3 , the present invention provides a battery pressure test method based on an explosion-proof mathematical model of a power battery, which includes the following steps:

[0043] (1) A computer control terminal 1 is set, which includes an embedded intelligent control chip integrated with dynamic pressure monitoring simulation software, a memory, and a display screen;

[0044] (2) Set a low-pressure pump, a low-pressure pump intake valve, a first pressure regulating valve, a first air filter, a first air pressure gauge, a solenoid valve, and two flow valves connected in sequence through the low-pressure gas passage ;A high-pressure pump, a high-pressure pump intake valve, a second pressure regulating valve, a second air filter, a second barometer, an air control proportional valve, and a pressure sensor connected sequentially through the high-pressure gas passage are set; A digital pressure controller is set again, the first pressure gauge is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com