A preparation method of a random crack test model

A technology of test models and cracks, which is applied in the preparation of rock mass mechanical properties test test models and the preparation of random crack test models, to achieve the effects of eliminating interference and influence, wide sources, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The experimental method is as follows:

[0040] Take the geometric similarity ratio C l is 6, that is, the model size is 1.5m×1.5m×1.5m, according to the model volume ratio, the number of cracks in the test model is calculated to be about 18, the thickness of the crack fragments used is about 0.1mm, the size is less than 5mm, and the shape is approximately rectangular; Bulk density similarity ratio C γ Take it as 1.5, then the elastic modulus is similar to the ratio C E =C l ×C γ =9

[0041] According to the intensity similarity ratio C R =C E =C l ×C γ =9, calculate the bulk density, compressive strength and elastic modulus of the model under the corresponding ratio, and select different material ratios according to the calculated model strength value.

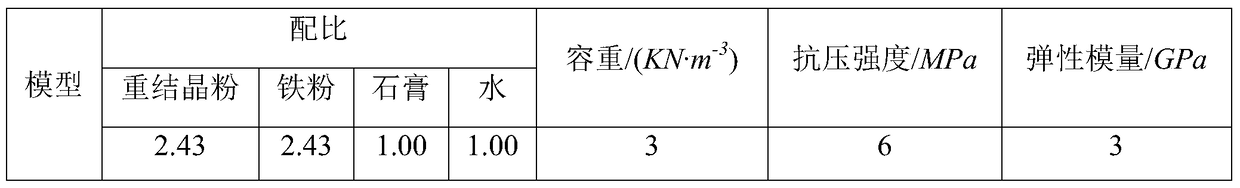

[0042] The aggregates are recrystallized powder and iron powder, and the cementing material is gypsum. The ratio and mechanical parameters are as follows:

[0043]

[0044] Mix the recrystallized powder, i...

Embodiment 2

[0053] Take the geometric similarity ratio C l is 9, that is, the size of the model is 2.25m×2.25m×2.25m. According to the model volume ratio, the number of cracks in the test model is calculated to be about 58. The thickness of the crack fragments used is about 0.1mm, the size is less than 5mm, and the shape is approximately rectangular; Bulk density similarity ratio C γ Take it as 1.5, then the elastic modulus is similar to the ratio C E =C l ×C γ =13.5

[0054] According to the intensity similarity ratio C R =C E =C l ×C γ =13.5, calculate the bulk density, compressive strength and elastic modulus of the model under the corresponding ratio, and select different material ratios according to the calculated model strength value.

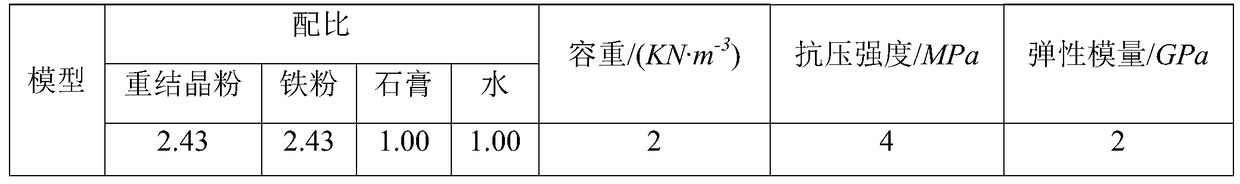

[0055]

[0056] The aggregates are recrystallized powder and iron powder, and the cementing material is gypsum. The ratio and mechanical parameters are as follows:

[0057] Mix the recrystallized powder, iron powder and gypsum with water ...

Embodiment 3

[0066] Take the geometric similarity ratio C l is 14, that is, the size of the model is 3.5m×3.5m×3.5m. According to the model volume ratio, the number of cracks in the test model is calculated to be about 220. The thickness of the crack fragments used is about 0.1mm, the size is less than 5mm, and the shape is approximately rectangular; Bulk density similarity ratio C γ Take it as 1.5, then the elastic modulus is similar to the ratio C E =C l ×C γ =21

[0067] According to the intensity similarity ratio C R =C E =C l ×C γ =21, calculate the bulk density, compressive strength and elastic modulus of the model under the corresponding ratio, and select different material ratios according to the calculated model strength value.

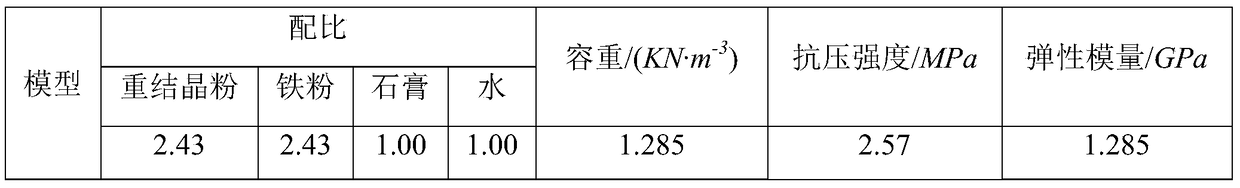

[0068] The aggregates are recrystallized powder and iron powder, and the cementing material is gypsum. The ratio and mechanical parameters are as follows:

[0069]

[0070] Mix the recrystallized powder, iron powder and gypsum with water in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com