Inner turbulent flow dirt cleaning rotor of heat exchanging pipe

A heat exchange tube and scale cleaning technology, which is applied to the field of interpolating components, can solve the problems of only scale prevention but not scale removal, etc., and achieves the effect of increasing the degree of turbulence and strengthening heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

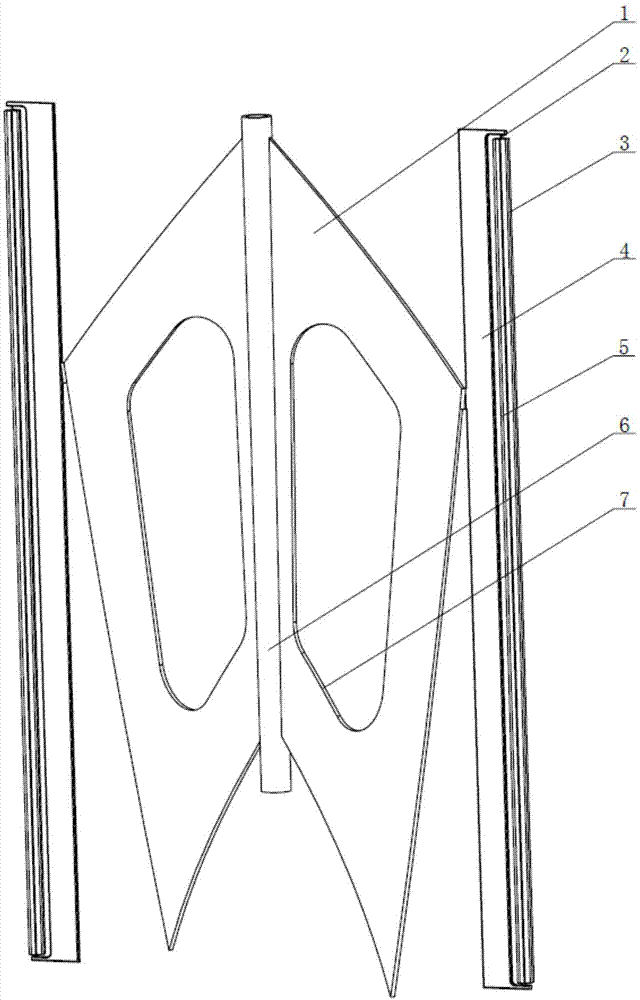

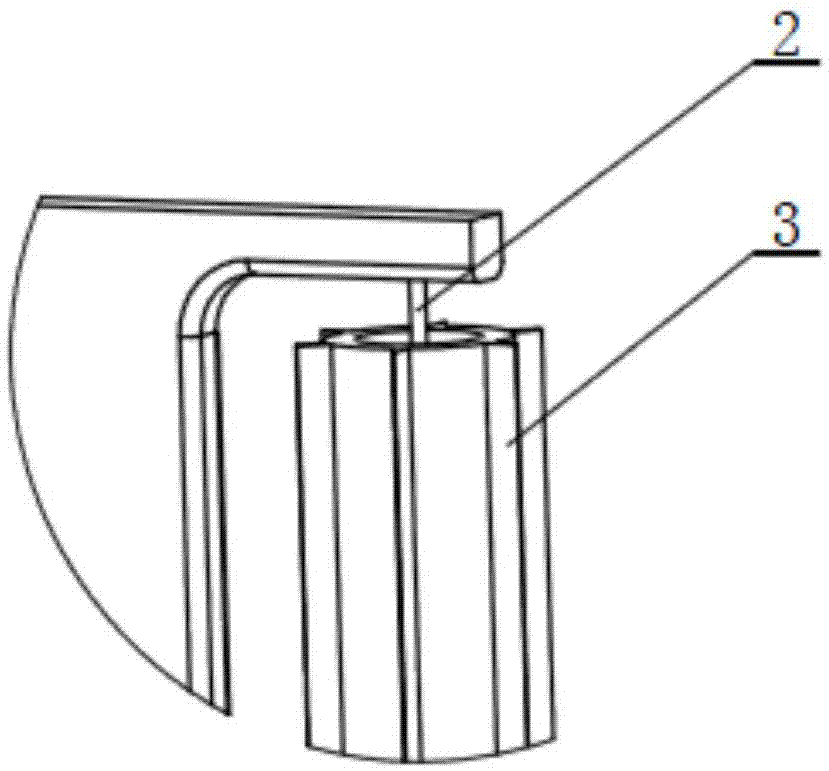

[0015] Such as Figures 1 to 2 As shown, the rotor 9 for turbulence cleaning in the heat exchange tube of the present invention includes inner blades 1, outer blades 4 and a central shaft 6, the outer blades 4 are connected to the inner blades 1, the inner blades 1 are connected to the central shaft 6, and the inner blades 1 are helical Shape; the inner blade 1 has a geometric through hole 7. The outer blade 4 is in the shape of a straight plate. There is a cylindrical roller 5 outside the outer blade 4. The central axis 2 of the roller is fixed on the outer blade 4. The cylindrical roller 5 rotates around the central axis 2 of the roller. There are strips on the cylindrical roller 4. Raised 3.

[0016] image 3 As a specific embodiment of the present invention, the scale cleaning and anti-scaling enhanced heat transfer device includes a turbulent flow cleaning rotor 9 in the heat exchange tube, a limiter 11, a heat exchange tube 12, a support frame 8 and a support shaft 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com