Novel crude oil normal-pressure tower top oil-gas heat exchanger

A technology of atmospheric tower and heat exchanger, applied in petroleum, cold exchange equipment and chemical industry, can solve problems such as cost and process difficulty, and achieve the effect of improving corrosion resistance, reducing environmental pollution and reducing industrial use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate description and understanding of the technical content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

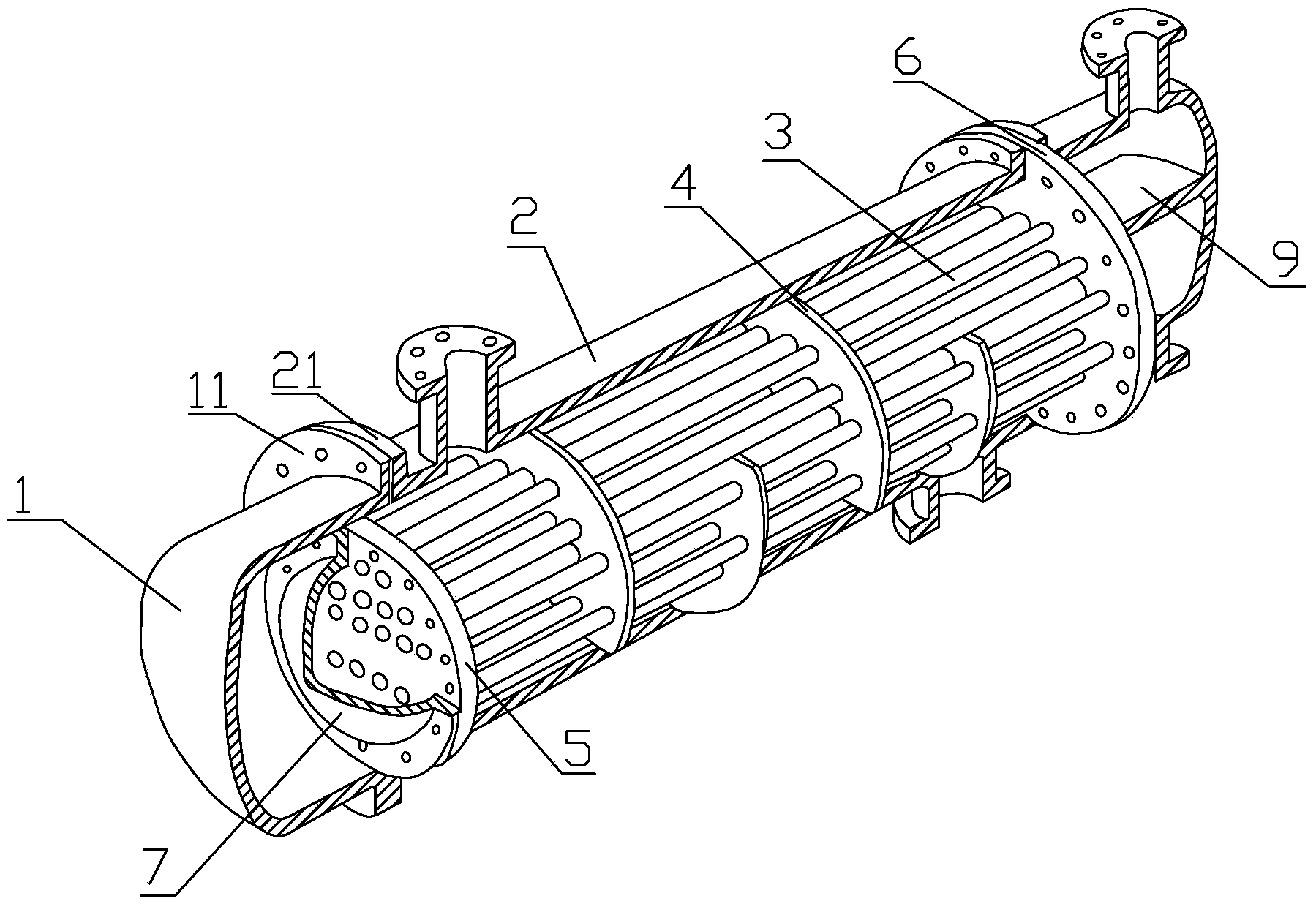

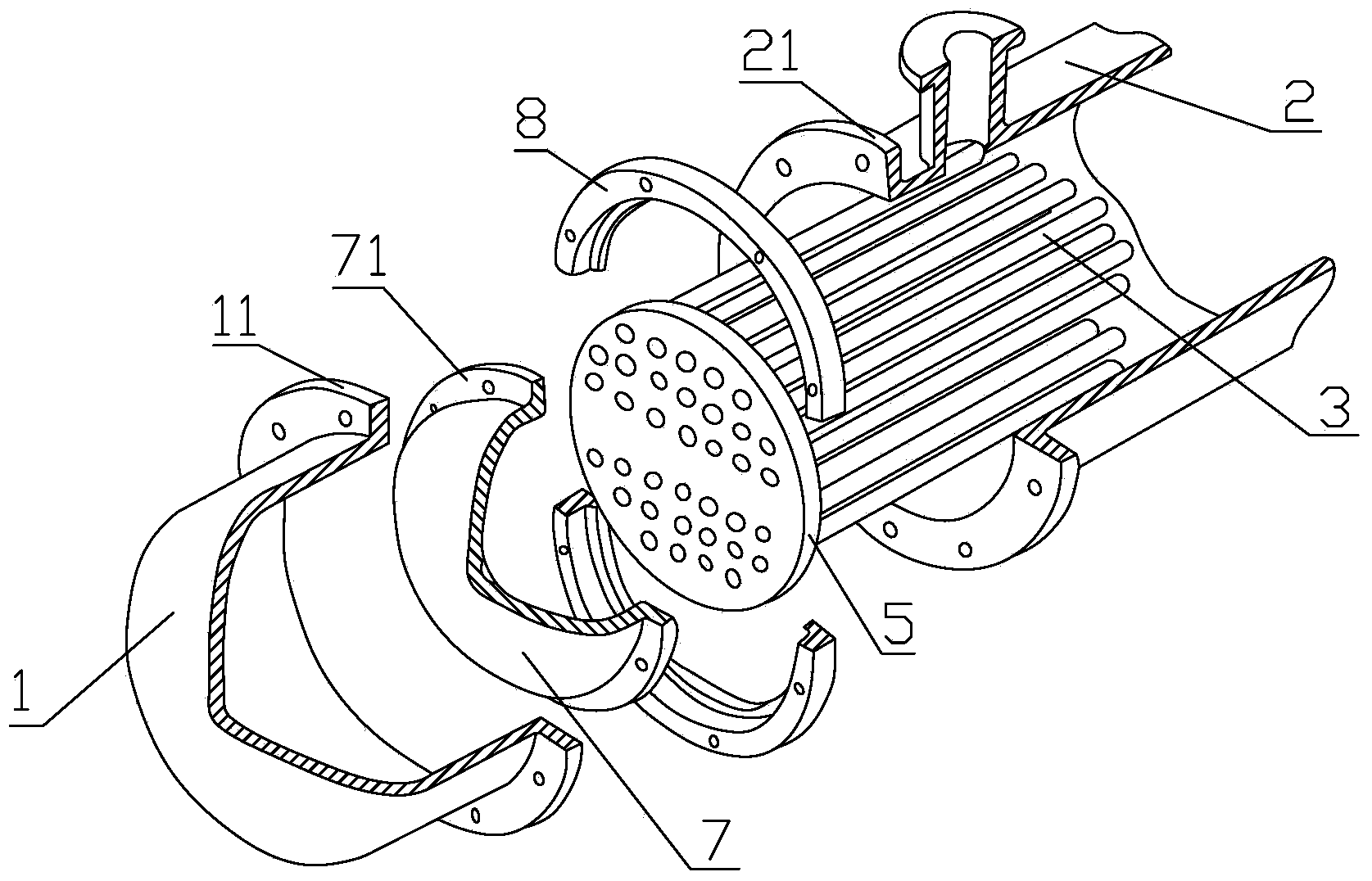

[0026] Such as figure 1 The floating head heat exchanger shown includes a tube box 1, a shell 2, a heat transfer tube 3, a baffle plate 4, a floating head tube sheet 5, a fixed tube sheet 6, a floating head 7 and a partition plate 9. Partition divider 9 is arranged in the tube box 1 that is fixed at one end of tube plate 6 . A sealing gasket II is provided between the fitting surface of the pipe box flange 11 at the floating head end and the shell flange 21 at the floating head end. The cover plate of the floating head is in the shape of a spherical crown. The flange 71 is connected with the shackle 8 arranged on the outer circle of the floating head tube plate 5 through the double-ended stud 10 . The left end peripheral surface of the floating head tube plate 5 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com