Heptafluoropropane recycling system

A technology of heptafluoropropane and recovery system, which is applied in liquefaction, solidification, lighting and heating equipment, etc., can solve environmental pollution and other problems, and achieve the effects of high recovery rate, low gas phase pressure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

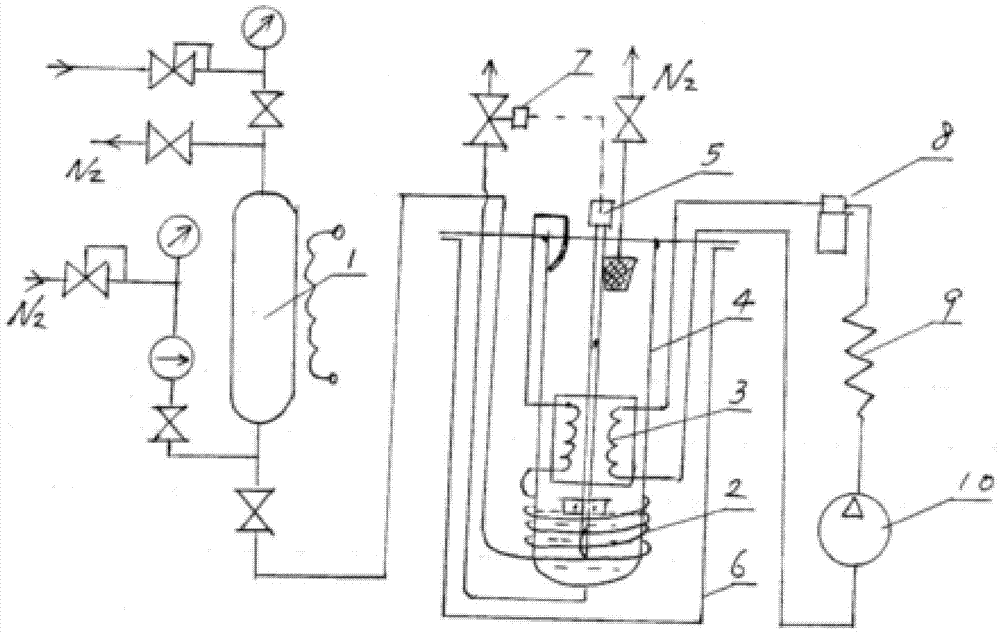

[0016] The present invention will be further described below according to the accompanying drawings.

[0017] Such as figure 1 As shown, the heat exchanger 3 is composed of inner and outer concentric coils, the inner coil is connected to the dryer 1, and the outer coil is connected to the condenser 9; the outer side of the heat exchanger 3 is provided with a low-temperature gas-liquid separator 4, and The inner and outer coils of the heat exchanger 3 are closely attached to the inner wall of the low-temperature gas-liquid separator 4; The outside of the separator 4; the low temperature gas-liquid separator 4 is provided with a liquid level controller 5, and the signal end of the liquid level controller 5 is connected to the solenoid valve 7.

[0018] The outside of the pre-cooler 2 is provided with a thermal insulation outer cylinder 6, and the thermal insulation outer cylinder 6 is an airtight thermal insulation container.

[0019] An expansion valve 8 is provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com