Method for manufacturing panel type solar heat collection device and panel type solar heat collection device manufactured with method

A technology of solar heat collection and production method, which is applied in the field of the production method of a flat-plate solar heat collection device and the products produced by implementing the method, can solve the problem that the solar water heater cannot guarantee the hot water demand, the unreasonable use and waste of high-level energy, and the solar radiation Instability and other problems, to achieve the effect of being conducive to wide popularization and application, ingenious structural design, and ensuring supply quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

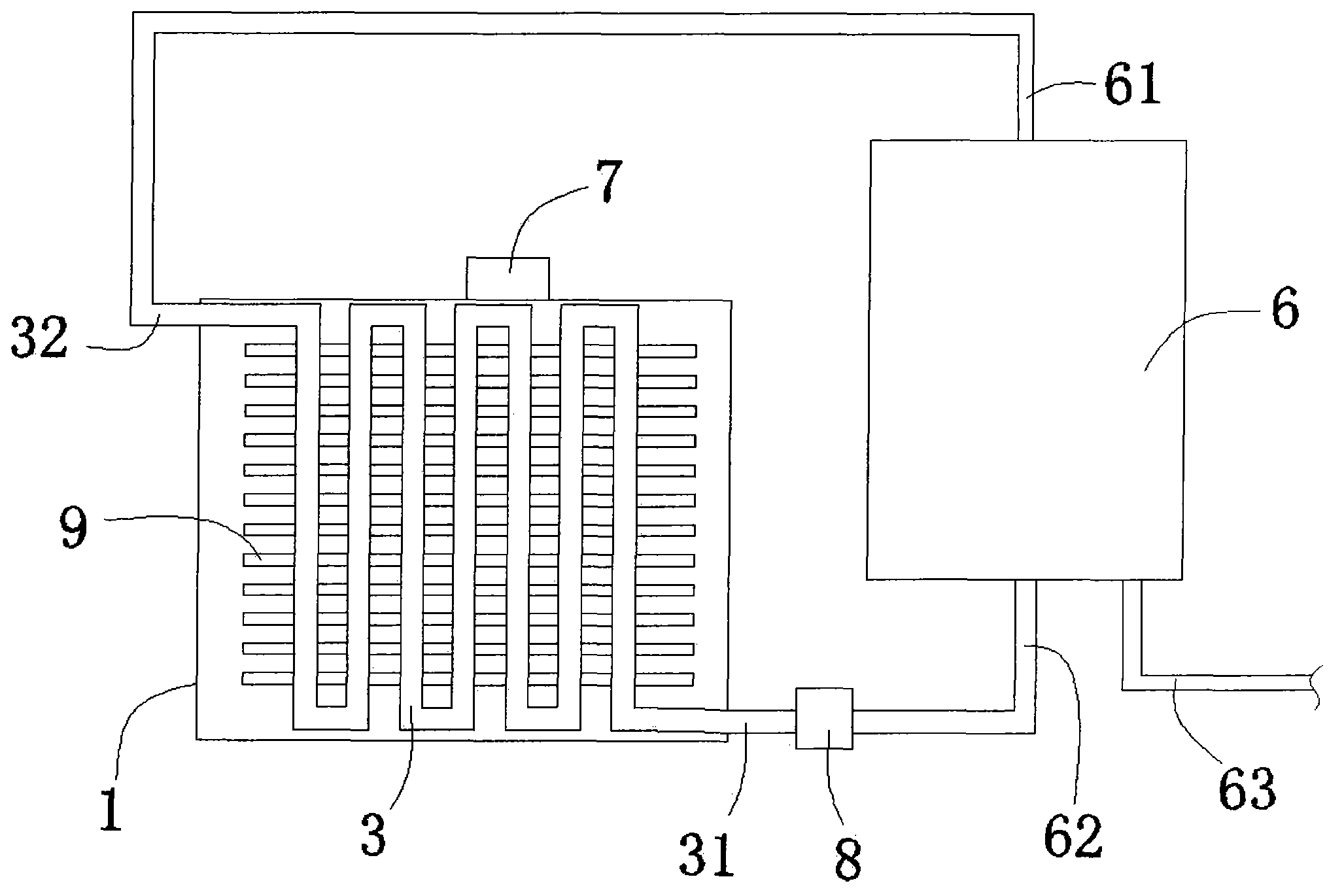

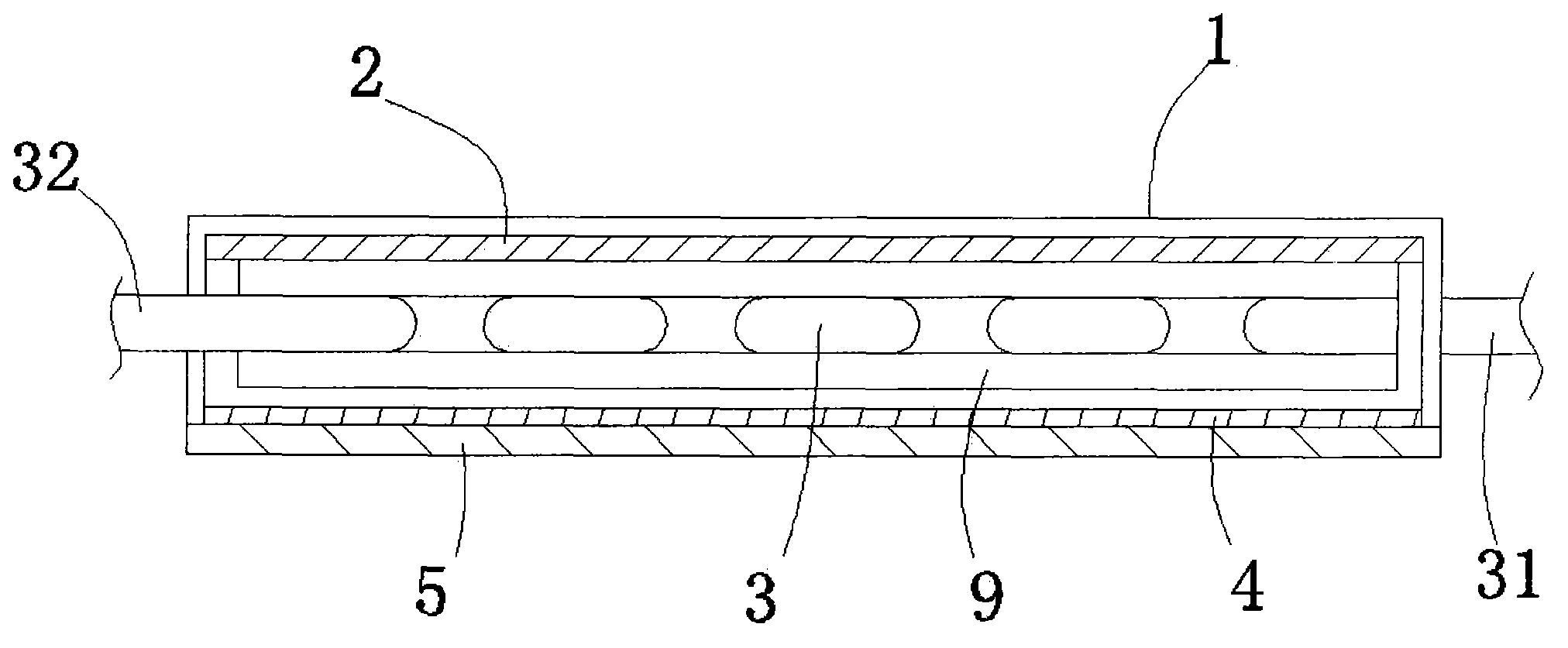

[0036] Example: see figure 1 and 2 , an embodiment of the present invention provides a method for manufacturing a flat-plate solar heat collector, which includes the following steps:

[0037] (1) Make a plate-shaped box body 1, offer light incident window on the side wall of this box body 1;

[0038] (2) A heat insulating layer 2 is provided on the other side wall of the box body 1 opposite to the light incident window;

[0039] (3) Prepare a heat collecting coil 3;

[0040] (4) Make some heat-collecting fins 9, and set the heat-collecting fins on the heat-collecting coil 3;

[0041] (5) The heat collecting coil 3 is arranged in the box body 1 corresponding to the position of the light incident window, and the heat collecting sheet on the heat collecting coil 3 is facing the light incident window, so that Both ends of the heat collecting coil 3 protrude from the box body 1 to form a water inlet 31 and a water outlet 32;

[0042] (6) Make a transparent glass 4 whose outlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com