Two-phase inhibition water mist drilling cooling device

A cooling device and fine water mist technology, which is applied in safety devices, earthwork drilling, mining equipment, etc., can solve the problems of complex arrangement of fine water mist system and inapplicability to coalfield fire extinguishing, etc., and achieve good effect of absorbing harmful smoke, The internal cross-sectional area is not easy and the effect of high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

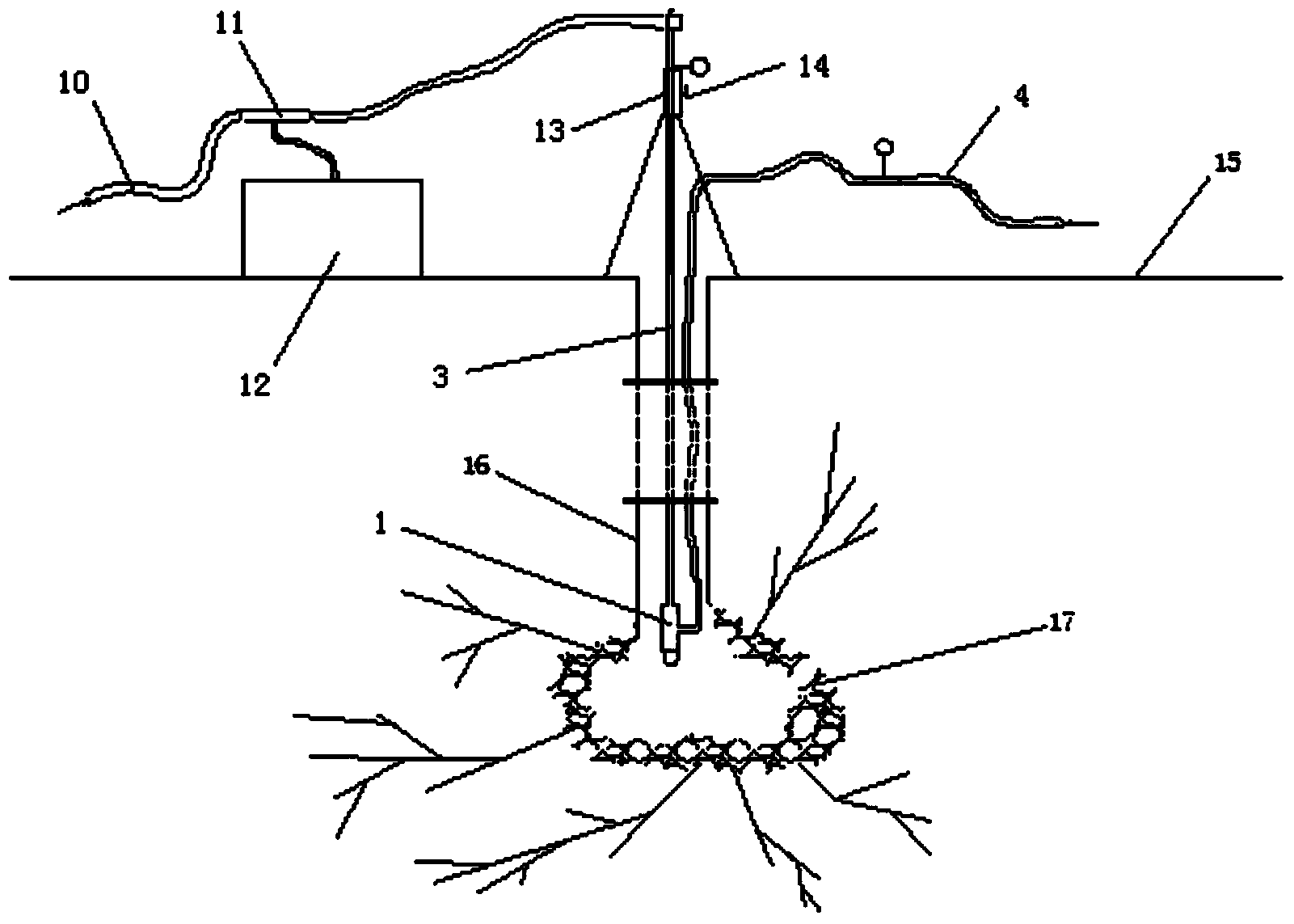

[0015] The present invention will be further described below in conjunction with accompanying drawing.

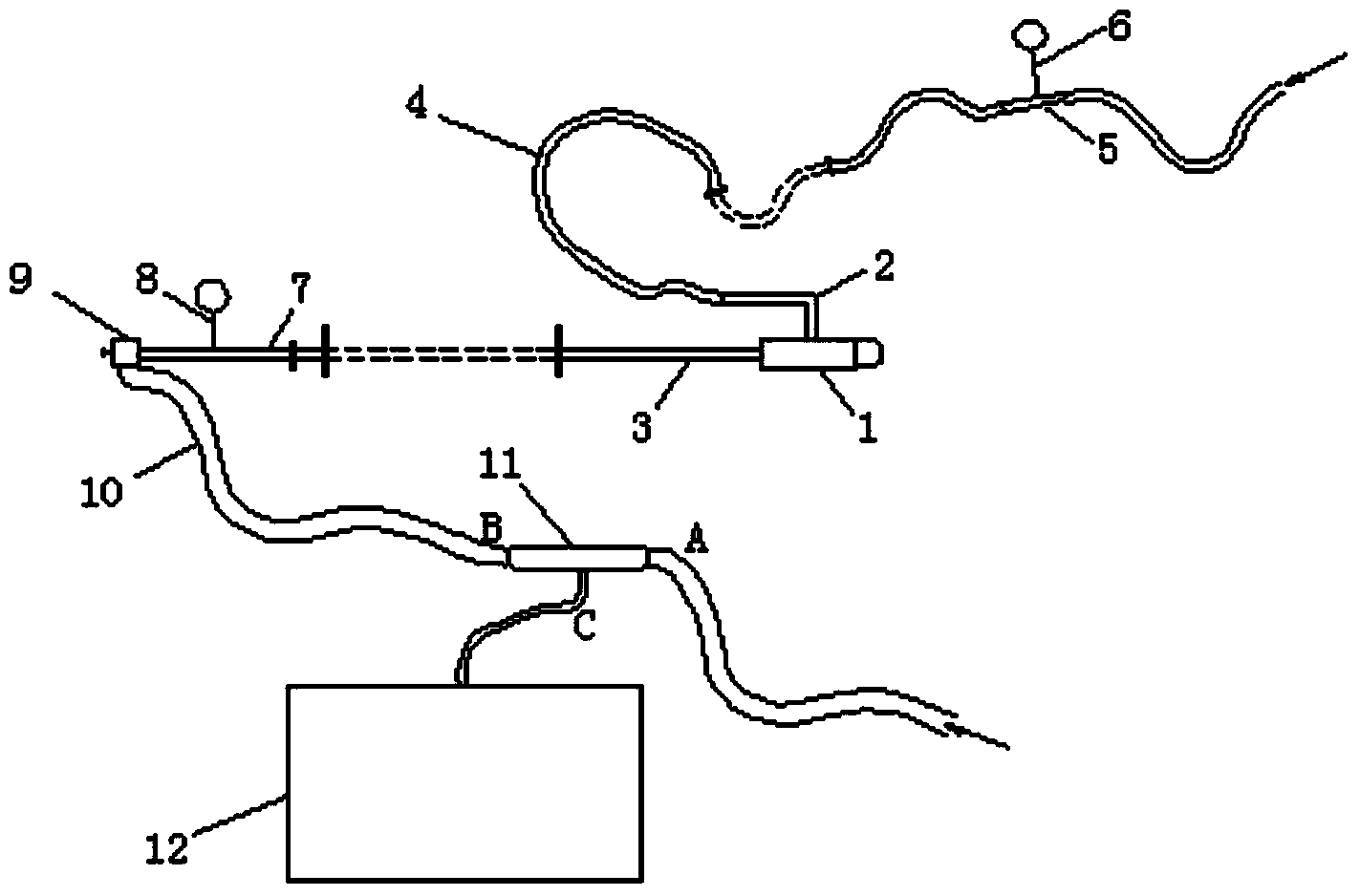

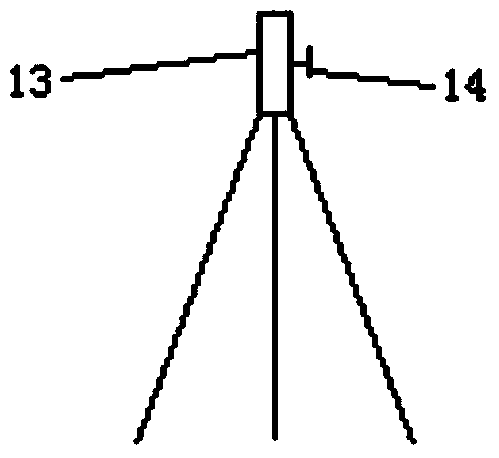

[0016] Such as figure 1 As shown, the two-phase resistive fine water mist drilling cooling device includes a two-phase atomizing nozzle 1, a right-angle metal elbow 2, an expandable metal tube 3, a high-pressure hose I4, a metal pressure measuring tube I5, and a gas pressure gauge 6. Metal pressure measuring tube II7, liquid pressure gauge 8, valve 9, high-pressure hose II10, proportional mixer 11 and retardant tank 12, the two-phase atomizing nozzle 1 is connected to one end of the right-angle metal elbow 2 and One end of the expandable metal tube 3 is connected; the other end of the right-angle metal elbow 2 is connected to the high-pressure hose I4 through a quick connector; the middle part of the high-pressure hose I4 is equipped with a metal pressure measuring tube I5, and a gas pressure tube I5 is installed on the metal pressure measuring tube I5. Pressure gauge 6; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com