Steel box girder scattered-splicing sliding device and installation method

A sliding device and steel box girder technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to implement and high engineering cost, and achieve the effect of saving large-scale equipment, strong adaptability, and safe and reliable implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

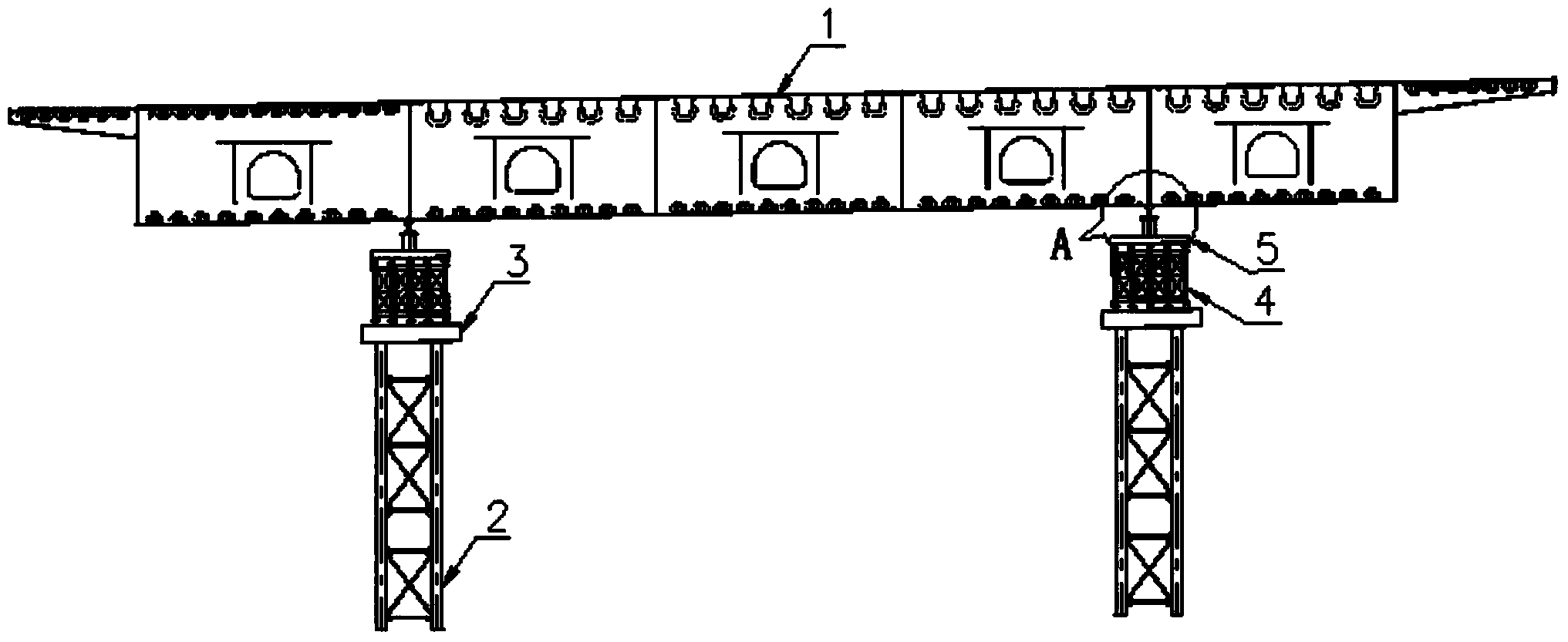

[0026] Such as Figure 1-2 As shown, a steel box girder bulk sliding device includes a steel pipe support 2, a load-bearing connecting beam 3 arranged on the top of the steel pipe support, and a sliding track structure installed on the load-bearing connecting beam.

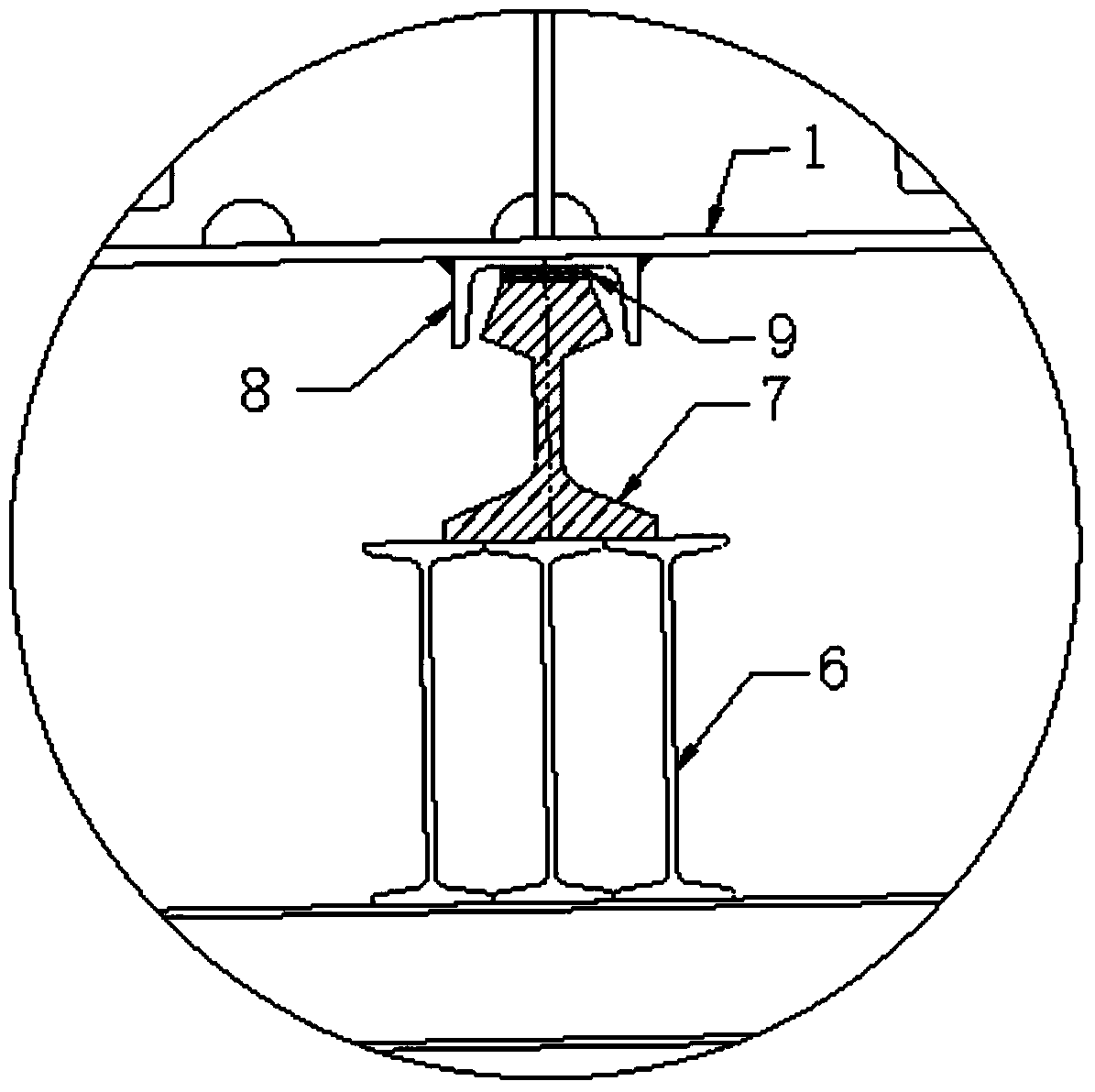

[0027] The sliding track structure includes a longitudinal Bailey beam 4 installed on the load-bearing connecting beam, a distribution beam 5 located on the Bailey beam, a longitudinal sleeper 6 located on the distribution beam, a steel rail 7 installed on the longitudinal sleeper, a Sliding block between steel box girder and rail.

[0028] The steel pipe support is a steel pipe support with few fulcrums.

[0029] Scissor braces are set between the steel pipe supports.

[0030] The sliding block includes a limit sliding channel steel 8 and a PTFE sliding plate 9 .

[0031] A method for installing steel box girders in bulk and sliding, comprising the following steps:

[0032] The first step: set up the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com