Synchronous setting circular knitting machine and method for producing knitted fabric containing thermoplastic fibers through same

A technology for circular knitting and fabric knitting, which is applied in shaping/stretching circular fabrics, knitting, weft knitting, etc. It can solve the problems of reducing heat energy utilization, affecting fabric quality, deteriorating the lubrication conditions of knitting equipment and the dimensional accuracy of needle cylinders, etc. problems, to achieve the effect of improving the utilization rate of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

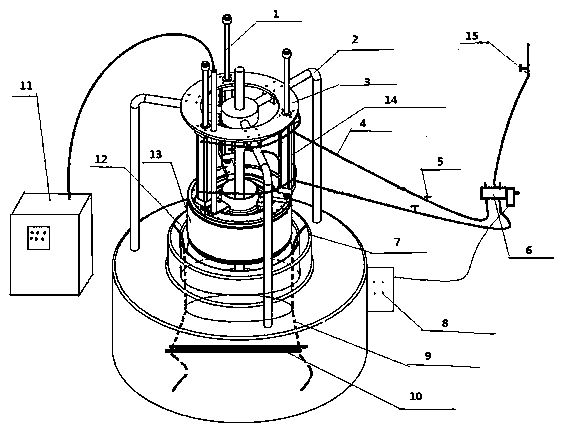

[0040] A specific embodiment of the method for producing knitted fabrics containing thermoplastic fibers by using the above-mentioned synchronously shaped circular knitting machine of the present invention includes the following A process or B process:

[0041] Process A: Use the above-mentioned synchronous shaping circular knitting machine to carry out synchronous presetting of weaving→dyeing→dehydration→cutting→open-width post-setting, and finally obtain the finished open-width knitted fabric;

[0042] Process B: Using the above-mentioned synchronous sizing circular knitting machine to carry out synchronous pre-sizing → dyeing → stripping

[0043] Water→wet stretching→drying→cylindrical shrinking and calendering, and finally the finished circular knitted fabric is obtained.

[0044] Specifically, the aforementioned weaving synchronous pre-setting process includes the following steps: the circular knitting machine is started, and the cylindrical knitted fabric moves to the pu...

Embodiment 1

[0059] Install the synchronous sizing device of this above-mentioned embodiment on 18 inches of 28G knitting single-sided small circular knitting machines. The weaving fabric is 40S cotton + 20D spandex high elastic single jersey. The rotating speed of the single-sided small circular knitting machine is 20 rpm, the number of equipment channels is 52, the cloth lowering speed is 13 mm / s, the height of the heat setting roller is 300 mm, the diameter of the heat setting roller is 370 mm, and the setting temperature is At 200°C, the qualitative time for the circular knitted fabric to pass through the outer surface of the heat setting roller is 23 seconds. The width of the finished circular knitted fabric is 520--530 mm. The fabric is then dyed—dehydrated—wet stretched—dried—tubular pre-shrunk and calendered, and finally the finished circular knitted fabric has a width of 460 mm and a square meter weight of 160 grams per square meter. The appearance quality, shrinkage rate and sq...

Embodiment 2

[0061] Install the synchronous sizing device of this above-mentioned embodiment on 30 inches of 28G knitting single-sided circular knitting machines. The weaving fabric is 150D polyester + 30D spandex high elastic single jersey. The rotary speed of the single-sided circular knitting machine is 16 rpm, the number of equipment channels is 90, the cloth lowering speed is 20 mm / s, the height of the heat setting roller is 320 mm, the diameter of the heat setting roller is 600 mm, and the setting temperature is 190 °C, the qualitative time for the circular knitted fabric to pass through the outer side of the heat setting roller is 16 seconds. The width of the finished circular knitted fabric is 900--930 mm. The fabric is then dyed—dehydrated—split—stentered, and finally the flat-width knitted finished fabric is obtained with a width of 1750 mm and a square meter weight of 180 grams per square meter. The appearance quality, shrinkage rate and square meter weight of the fabric all m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com