Carbon nanotube modified polyvinyl akohol nano-fiber yarn and preparing method thereof

A technology of carbon nanotube modification and polyvinyl alcohol, applied in fiber treatment, fiber chemical characteristics, yarn, etc., can solve problems such as increased equipment investment, increased difficulty in product quality control, increased process parameters, etc., to achieve increased strength , blending and spinning processes are easy to control, and the effect of reducing volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

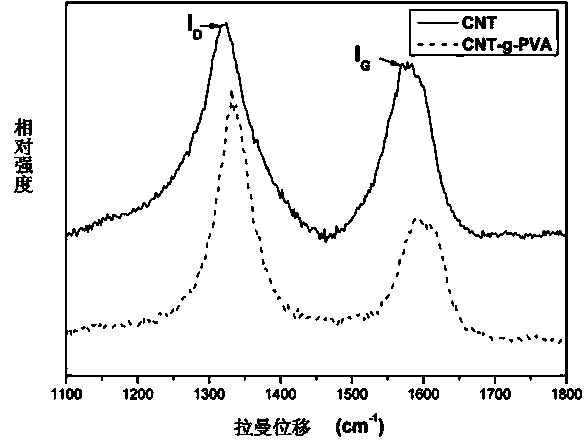

[0029] Weigh an appropriate amount of aluminum trichloride, add the anhydrous solvent dimethyl sulfoxide (DMSO) dropwise to aluminum trichloride in an ice-water mixed bath with stirring, and heat to trichloride after the addition is complete. Aluminum chloride is completely dissolved, and is made into a 4wt% aluminum chloride solution. Add polyvinyl alcohol to anhydrous dimethyl sulfoxide to form a solution with a concentration of 5 wt %, add carbon nanotubes at a mass ratio of multi-walled carbon nanotubes to polyvinyl alcohol at a ratio of 1:10, and mix thoroughly. The dimethyl sulfoxide solution of polyvinyl alcohol and carbon nanotubes was poured into the solution of aluminum trichloride, and reacted at 70° C. for 24 hours. Pour the reaction solution into a solution of methanol and dilute hydrochloric acid (0.1mol / L) with a mass ratio of 1:2 to precipitate, centrifuge at 13000rpm, separate and dry to obtain polyvinyl alcohol-modified carbon nanotubes , denoted as CNT-g-PV...

Embodiment 2

[0034] Weigh an appropriate amount of aluminum trichloride, add the anhydrous solvent dimethyl sulfoxide (DMSO) dropwise to aluminum trichloride in an ice-water mixed bath with stirring, and heat to trichloride after the addition is complete. Aluminum chloride is completely dissolved to form a 10wt% aluminum chloride solution. Add polyvinyl alcohol to anhydrous dimethyl sulfoxide to form a solution with a concentration of 20wt%, add carbon nanotubes at a mass ratio of 1:20 to multi-walled carbon nanotubes and polyvinyl alcohol, mix thoroughly, and The dimethyl sulfoxide solution of polyvinyl alcohol and carbon nanotubes was poured into the solution of aluminum trichloride, and reacted at 90° C. for 12 hours. Pour the reaction solution into a solution of methanol and dilute hydrochloric acid (0.1mol / L) with a mass ratio of 1:2 to precipitate, centrifuge at 13000rpm, separate and dry to obtain polyvinyl alcohol-modified carbon nanotubes .

[0035]Add modified carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com