Automatic continuous liquid exchange cell culture device

A cell culture and automatic technology, applied in tissue cell/virus culture devices, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems that the influence of cell samples cannot be ignored, and it is difficult to precisely control the amount of culture medium. To achieve the effect of high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

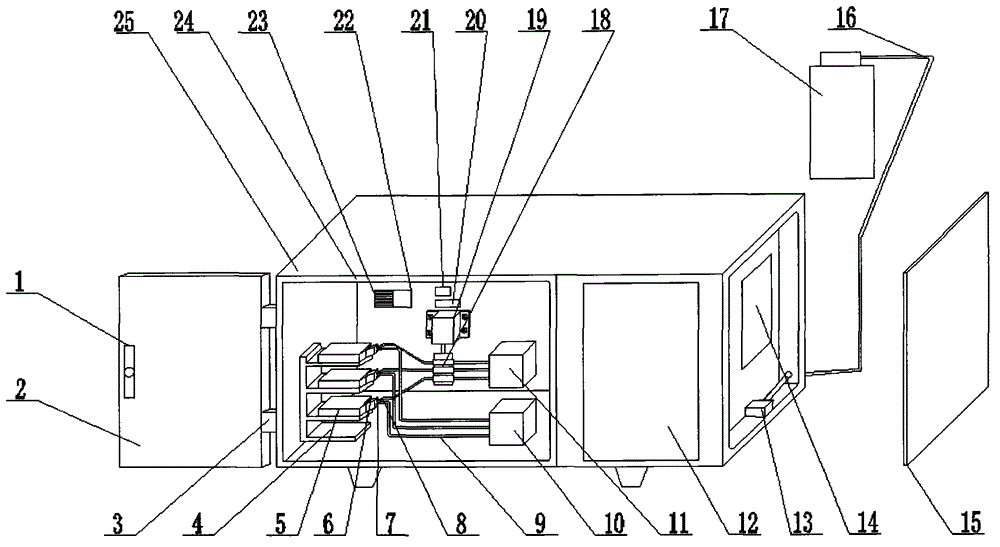

[0016] Such as figure 1 As shown, in the cell culture device for automatic and continuous liquid exchange of the present invention, the main structure 25 is integrally formed by machining of hard aluminum alloy LY12, and the overall size is 541.6×272×200 (unit: mm), and the surface is sprayed with black plastic. The main cover 2 is also integrally formed by LY12 machining, and the surface is sprayed with black plastic. It is installed on the left side of the front of the main structure 25 through two standard flaps 3. The cover lock 1 is processed by stainless steel 1Cr18Ni9Ti and can rotate in the installation hole of the main cover 2. The cover lock 1 can be rotated 90° to lock the main cover 2 on the main structure 25, and then rotated 90° to unlock it; the right side cover 15 is an aluminum alloy LY12 plate, fixed to the right side of the main structure 25 by 12 M3 screws.

[0017] The insulation structure 24 is foamed with non-toxic PC material, with an effective thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com