Tandem-type fermentor group and use method thereof

A tandem fermenter and fermenter technology, which is applied in biochemical equipment and methods, wine preparation, alcoholic beverage preparation, etc., can solve the problem that the temperature of the fermenter is difficult to control uniformly, cannot be in contact with grape skins, cannot be recycled, etc. problem, to achieve the effect of wide range of use, large production capacity, and reduction of human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

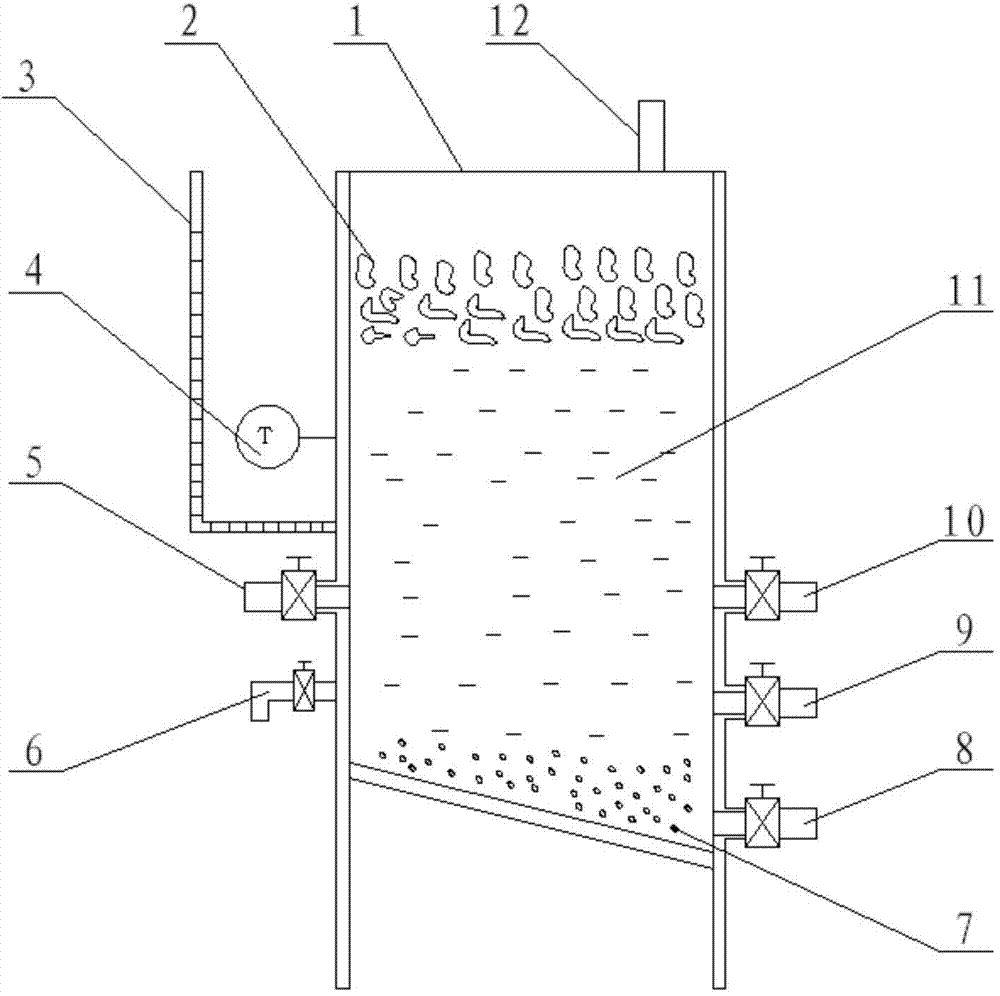

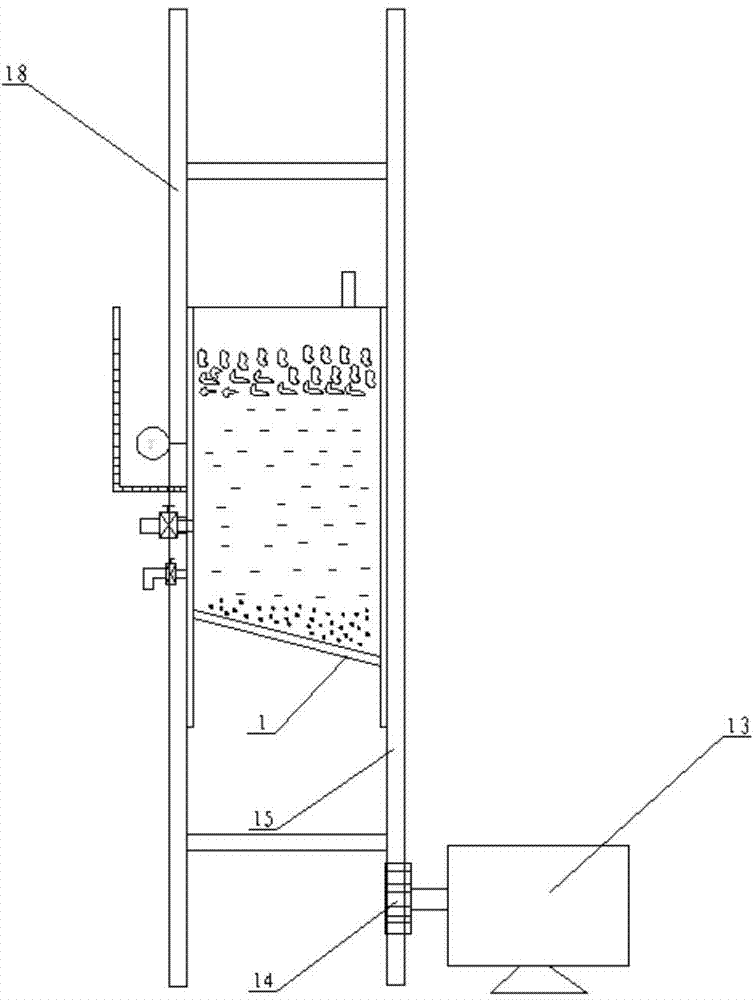

[0032] like Figure 1 to Figure 5 Shown, a kind of tandem fermenter group comprises two fermentors 17 and a mobile fermenter 1, and is provided with connecting pipe 16 between fermentor 17 and mobile fermenter 1, and fermentor 17 and mobile fermenter 1 They are communicated with each other through the connecting pipe 16, and the mobile fermenter 1 can move up and down under external drive, and the fermentation liquid 11 in the fermenter 17 and the mobile fermenter 1 is under the action of gravity due to the height difference between the fermentors. Flow into or out of each other via connecting pipe 16 .

[0033] The fermenter 17 and the upper end of the mobile fermenter 1 are provided with a vent valve 12, and the inner bottom of the fermenter 1 is designed as an inclined bottom.

[0034] The side walls of the fermentation tank 17 and the mobile fermentation tank 1 are provided with connection valve I5, connection valve II10, discharge valve I6, feed valve 9 and discharge val...

Embodiment 2

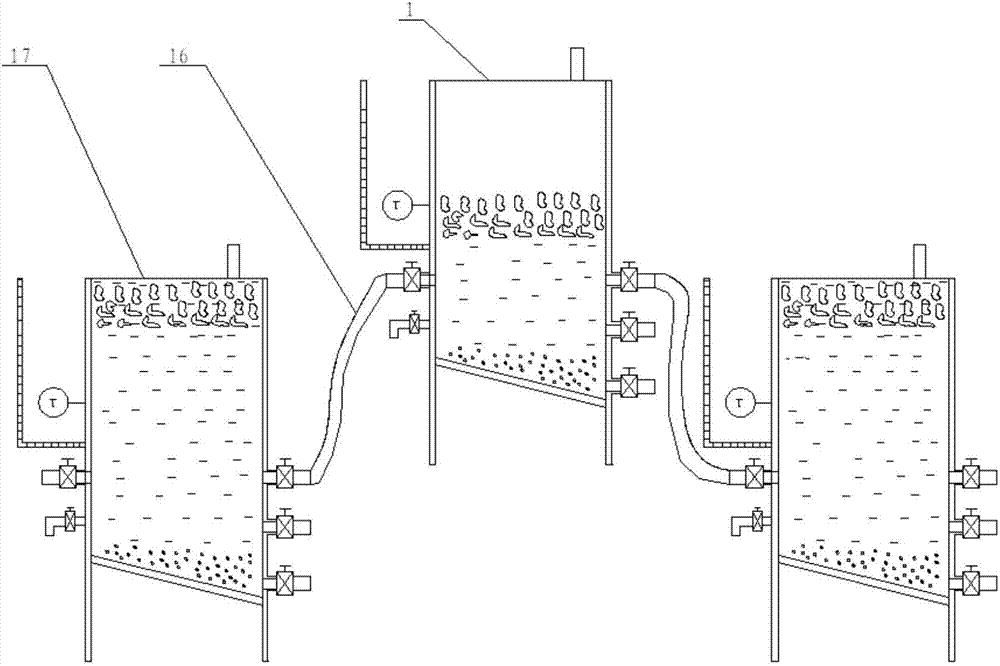

[0044] A series fermenter group, comprising three fermentors 17 and a mobile fermenter 1, and a connecting pipe 16 is provided between the fermenter 17 and the mobile fermenter 1, and the fermenter 17 and the mobile fermenter 1 pass through The connecting pipes 16 communicate with each other, and the mobile fermenter 1 can move up and down under the external drive, and the fermented liquid 11 in the fermenter 17 and the mobile fermenter 1 is subjected to the action of gravity due to the height difference between the fermenter, and passes through the connecting pipe. 16 flow into or out of each other.

[0045] The fermenter 17 and the upper end of the mobile fermenter 1 are provided with a vent valve 12, and the inner bottom of the fermenter 1 is designed as an inclined bottom.

[0046] The side walls of the fermenter 17 and the mobile fermenter 1 are provided with connection valve I5, connection valve II10, discharge valve I6, feed valve 9 and discharge valve II8, connection v...

Embodiment 3

[0056] A series fermenter group, comprising five fermentors 17 and two mobile fermentors 1, and a connecting pipe 16 is provided between the fermentors 17 and the mobile fermentors 1, and between the fermentors 17 and the mobile fermentors 1 The connecting pipe 16 communicates with each other, and the mobile fermenter 1 can move up and down under external drive, and the fermentation liquid 11 in the fermenter 17 and the mobile fermenter 1 is subjected to gravity due to the difference in height between the fermentors. The tubes 16 flow into and out of each other.

[0057] The fermenter 17 and the upper end of the mobile fermenter 1 are provided with a vent valve 12, and the inner bottom of the fermenter 1 is designed as an inclined bottom.

[0058] The side walls of the fermenter 17 and the mobile fermenter 1 are provided with connection valve I5, connection valve II10, discharge valve I6, feed valve 9 and discharge valve II8, connection valve I5 and connection valve II10 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com