Spongy cleaning solid and preparation method thereof

A cleaning solid, sponge-like technology, used in chemical instruments and methods, detergent floats, preparations for skin care, etc., can solve the problems of waste, inconvenience, sinking to the bottom, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

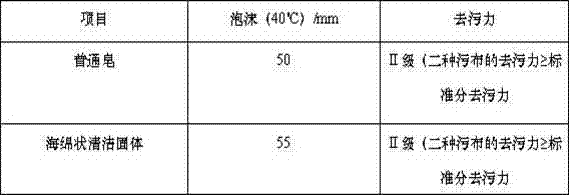

Image

Examples

Embodiment 1

[0022] A spongy cleansing solid consisting of the following components by weight percent:

[0023] Sodium Cocoyl Isethionate 80%

[0024] Potassium Cocoyl Glycinate 5%

[0025] Lavender essential oil 2%

[0026] Perfluorobutyl methyl ether 3%

[0027] Methyl perfluoroisobutyl ether 10%

[0028] Put sodium cocoyl isethionate and potassium cocoyl glycinate into the reactor, heat to 60~70°C, stir slowly (350~400rpm / min) until completely melted; then cool down to 40°C, add lavender The essential oils are mixed well and kept at a constant temperature. Pour the above molten liquid into a reactor 6 times larger than its volume, keep a constant temperature of 35°C~40°C, add perfluorobutyl methyl ether and methyl perfluoroisobutyl ether, and stir at 200rpm / min for 10 minutes , Take it out with a glass, measure the density with a specific gravity meter, the density is 0.50, that is, the gas content is 58%, stop stirring, and pour it into the mold immediately to make it solidify qui...

Embodiment 2

[0034] A spongy cleansing solid consisting of the following components by weight percent:

[0035] Sodium Palmitoleate 21%

[0036] Sodium Cocoate 15%

[0037] Sodium Lauroyl Glutamate 12%

[0038] Deionized water 15%

[0039] Glycerin 10%

[0040] Lavender essential oil 2%

[0041] Sodium bicarbonate 15%

[0042] Citric acid 10%

[0043]Add sodium palmitoleate, sodium cocoate, sodium lauroyl glutamate, 10% deionized water (reserve 5% for dissolving citric acid) and glycerin into the reactor, heat to 60-70°C, stir and melt completely. Then cool down to 50°C, add lavender essential oil and mix evenly, keep constant temperature. Pour the above molten liquid into a reactor 6 times larger than its volume, keep a constant temperature of 55°C~60°C, then put sodium bicarbonate into the reactor, stir to dissolve the sodium bicarbonate completely, and then add the citric acid solution Pour into the reactor, stir at 150rpm / min for 10 minutes, take it out with a glass, measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com