Polyamide amine flowing modifier for mineral oil based drilling fluid and preparation method of modifier

A technology of polyamidoamine and flow pattern regulator, which is applied in the field of drilling fluid to achieve the effects of saving energy consumption, enhancing interaction and reducing control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

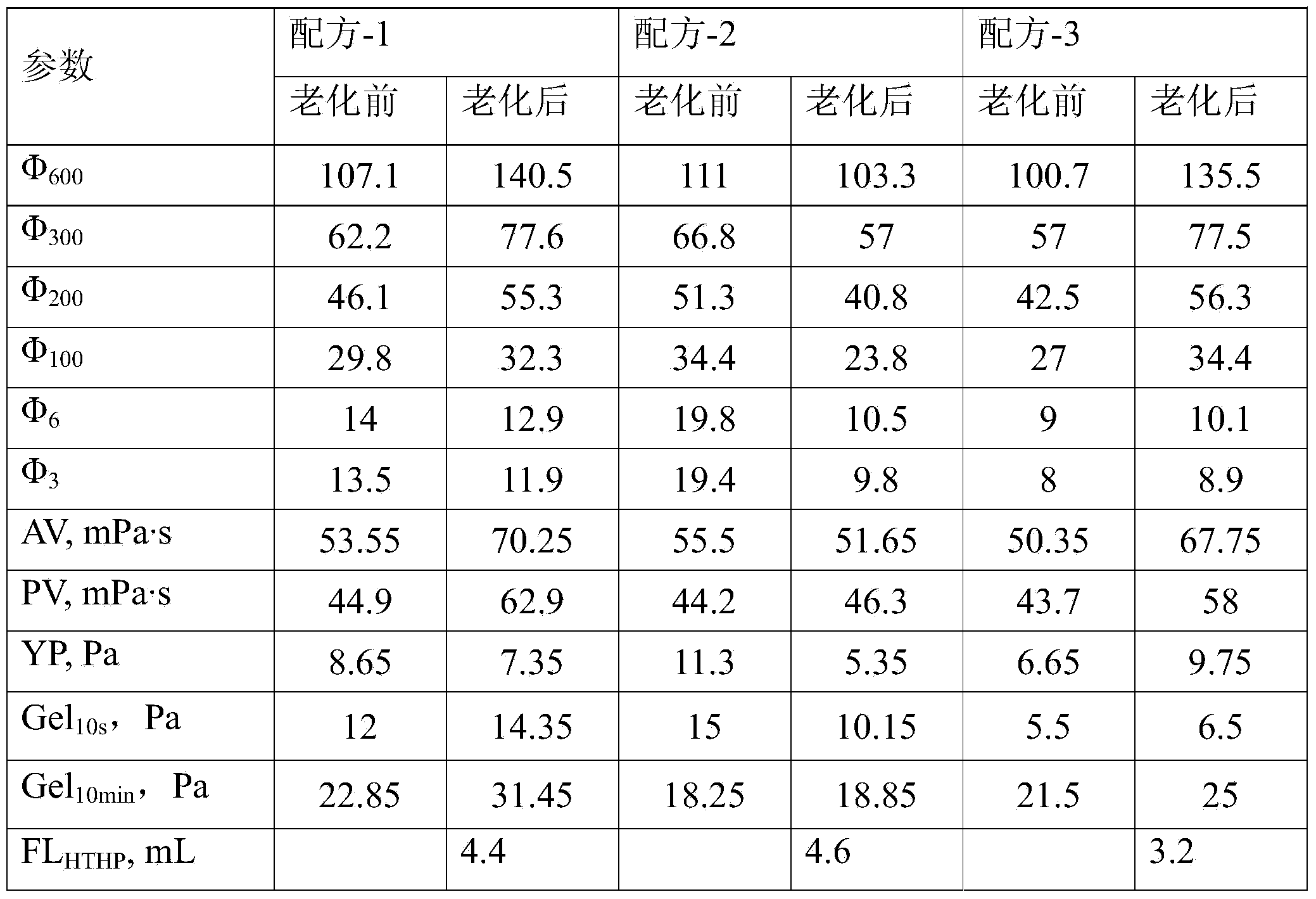

Embodiment 1

[0023] In a four-port reactor equipped with a stirrer, a thermometer, a nitrogen gas device (inert gas protection and carrying water vapor) and a Dean-Stark receiver, add diethylenetriamine according to the ratio of the number of amine groups to the number of carboxyl groups at 0.4:1.0 and dimer fatty acid (78wt% dimer acid, 10wt% monomeric acid and 12wt% trimer acid), heated to 110°C in a constant temperature oil bath for 0.5h, then heated to 150°C, and reacted for 3.0h to obtain the mineral Polyamidoamine flow pattern modifier for oil-based drilling fluids. The obtained mineral oil-based drilling fluid is mixed uniformly with the polyamidoamine flow pattern regulator and the solvent at a mass ratio of 1:1 to obtain the product PAA-1; wherein: the solvent is dipropylene glycol monomethyl ether with a mass ratio of 60:40 Mixture with 5# industrial white oil.

Embodiment 2

[0025] In a four-port reactor equipped with a stirrer, a thermometer, a nitrogen gas device (inert gas protection and carrying water vapor) and a Dean-Stark receiver, add triethylenetetramine according to the ratio of the number of amine groups to the number of carboxyl groups at 0.7:1.0 and dimer fatty acid (92wt% dimer acid, 2.5% monomeric acid and 5.5% trimer acid), heated to 110°C in a constant temperature oil bath for 0.5h, then heated to 160°C, and reacted for 2.0h to obtain the mineral Polyamidoamine flow pattern modifier for oil-based drilling fluids. The obtained mineral oil-based drilling fluid is mixed uniformly with the polyamidoamine flow pattern regulator and the solvent at a mass ratio of 1:1 to obtain the product PAA-2; wherein: the solvent is dipropylene glycol monomethyl ether with a mass ratio of 60:40 Mixture with 5# industrial white oil.

Embodiment 3

[0027] In a four-port reactor equipped with a stirrer, a thermometer, a nitrogen gas device (inert gas protection and carrying water vapor) and a Dean-Stark receiver, add triethylenetetramine at a ratio of 0.8:1.0 of the number of amine groups to the number of carboxyl groups and dimer fatty acid (98wt% dimer acid and 2wt% monomeric acid), heated to 110°C in a constant temperature oil bath for 0.5h, then heated up to 160°C, and reacted for 1.5h to obtain the polymer for mineral oil-based drilling fluid of the present invention. Amidoamine flow regulator. The obtained mineral oil-based drilling fluid is mixed uniformly with the polyamidoamine flow pattern regulator and the solvent at a mass ratio of 1:1 to obtain the product PAA-3; wherein: the solvent is dipropylene glycol monomethyl ether with a mass ratio of 60:40 Mixture with 5# industrial white oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com