Terminal group treatment method of PTFE (polytetrafluoroethylene) suspension resin

A processing method and technology for suspending resin, applied in lighting and heating equipment, drying, furnace types, etc., can solve the problem of needing hundreds of meters, and achieve the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

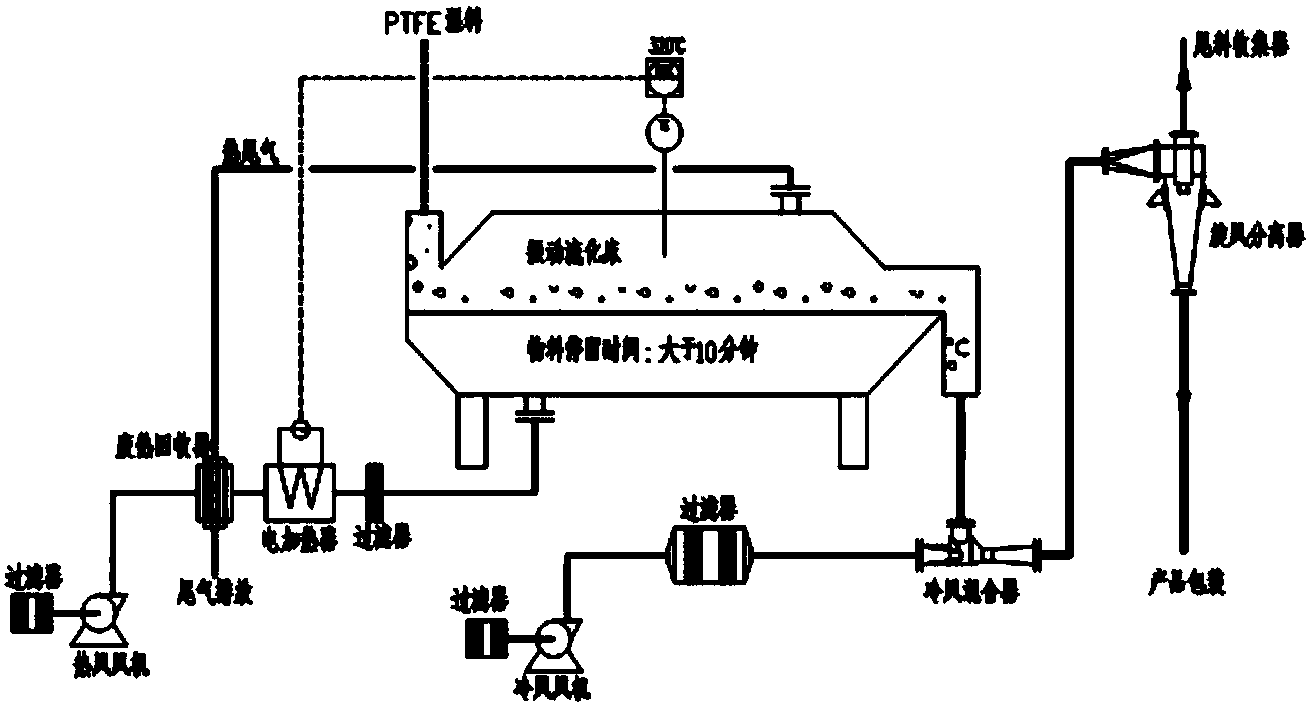

[0034] Take a PTFE suspension resin synthesized by a certain production as an example, and dry it, such as figure 2 Shown:

[0035] 1). The air in the air duct at a flow rate greater than 20m / s enters the hot air blower after coarse-effect filtration, is preheated to 120°C by the waste heat recovery device, and then enters the electric heater through the medium-efficiency filter to be heated to 360°C. The filter enters the vibrating fluidized bed;

[0036] 2) The PTFE wet material after vibrating and sieving water enters the vibrating fluidized bed at 600kg / h, staying for 15 minutes, and controlling the temperature in the vibrating fluidized bed to 270℃, so that the PTFE wet material and air are fully under high temperature conditions. Contact, cracking to generate a mixed gas of sulfur trioxide and carbon dioxide;

[0037] 3) After the cracking, the dried PTFE material is reduced to 30°C by a cold air mixer, and is separated by a cyclone separator and then packaged. The separated...

Embodiment 2

[0040] The wet PTFE material was dried by the method of Example 1.

[0041] Among them, in step 2), the temperature in the vibrating fluidized bed is 290°C; in step 3), the dried PTFE material is reduced to 20°C by a cold air mixer;

[0042] After the separation of the finished PTFE product, the yield of the finished product is 98%, and its water content is 0.011%. Using infrared detection, the finished PTFE product contains only 15% of the end groups compared to the wet PTFE material.

Embodiment 3

[0044] The wet PTFE material was dried by the method of Example 1.

[0045] Among them, in step 2), the temperature in the vibrating fluidized bed is 250°C; in step 3), the dried PTFE material is reduced to 35°C by a cold air mixer;

[0046] After the separation of the finished PTFE product, the yield rate of the finished product is 98%, and its water content is 0.012%. Using infrared detection, the finished PTFE product contains only 25% of the end groups compared to the wet PTFE material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com