Method for direct separation of agarose and agaropectin from agar

A technology for agarose and agar ester, which is applied in the field of separating agarose and agar ester, and achieves the effects of cheap raw materials, simple and practical preparation process, low cost and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

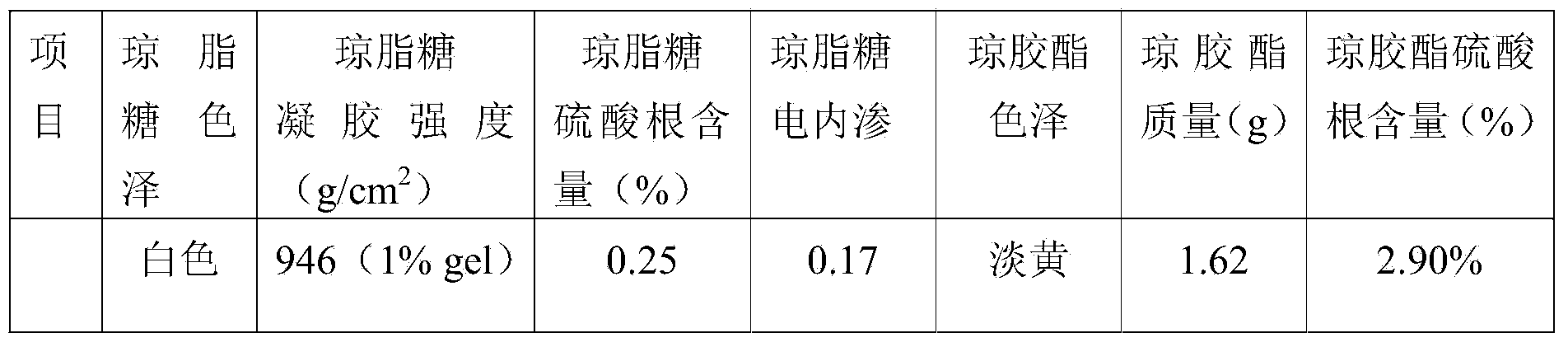

Embodiment 1

[0020] A kind of method of the present invention directly separates and prepares agarose and agar ester from agar, specifically comprises the steps:

[0021] a. Take 16g agar (646g / cm 2 , 1% gel), prepare an agar solution with a concentration of 1wt%, heat and stir to dissolve into a translucent solution, and place it in a water bath at 60°C for 30 minutes at a constant temperature; wherein, the agar used is derived from Gracilaria, Geliflower or Egunia Marine red algae plants;

[0022] b. Take 100g of PEG to prepare a PEG solution with a concentration of 60wt%, heat and stir in a water bath to dissolve it completely and keep the temperature at 60°C for 30min, wherein the molecular weight of PEG is 2,000;

[0023] c. Quickly mix the agar solution obtained in step a and the PEG solution obtained in step b in a water bath at 60°C and stir continuously. After stirring for 5 minutes, a suspension with white precipitate is obtained. Stop stirring and let it stand for 10 minutes. ...

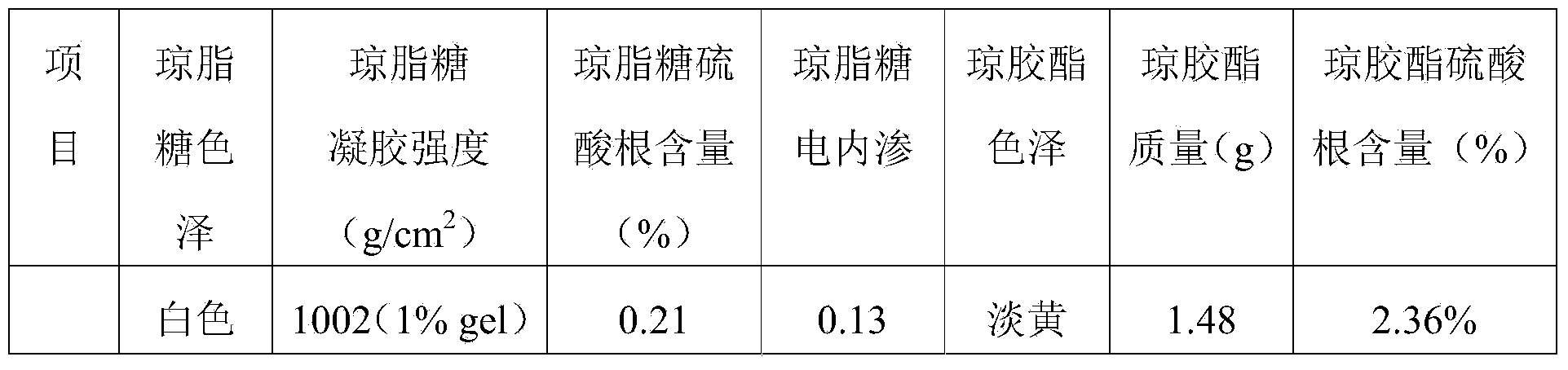

Embodiment 2

[0034] A kind of method of the present invention directly separates and prepares agarose and agar ester from agar, specifically comprises the steps:

[0035] a. Take 16g agar (646g / cm 2 , 1% gel), prepare an agar solution with a concentration of 3wt%, heat and stir to dissolve into a translucent solution, and place it in a water bath at 90°C for 30 minutes at a constant temperature; wherein, the agar used is derived from Gracilaria, Geliflower or Egunia Marine red algae plants;

[0036] b. Take 80g of PEG to prepare a PEG solution with a concentration of 50wt%, heat and stir in a water bath to completely dissolve and keep the temperature at 90°C for 30min, wherein the molecular weight of PEG is 4,000;

[0037] c. Mix the agar solution obtained in step a with the PEG solution obtained in step b in a water bath and stir continuously. After the stirring time is maintained for 10 minutes, stop stirring to obtain a suspension with a white precipitate. After standing for 10 minutes...

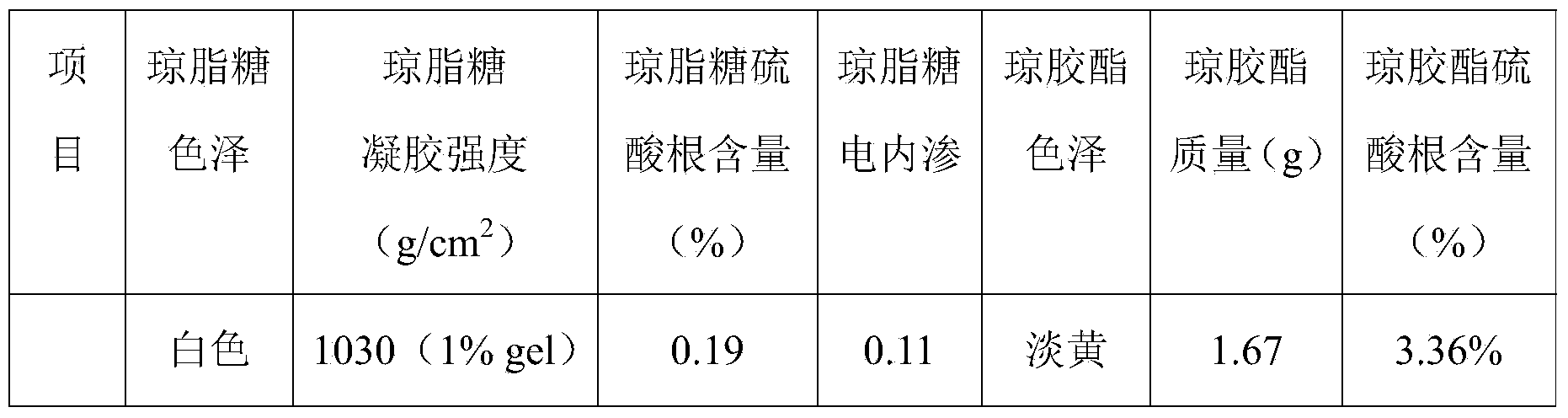

Embodiment 3

[0048] a. Take 16g agar (646g / cm 2 , 1% gel), prepare an agar solution with a concentration of 4wt%, heat and stir to dissolve it into a translucent solution, and place it in a water bath at 80°C for 30 minutes at a constant temperature; wherein, the agar used comes from Gracilaria, Geliflower or Egunia Marine red algae plants;

[0049] b. Take 100g of PEG to prepare a PEG solution with a concentration of 40wt%, heat and stir in a water bath to dissolve it completely and keep the temperature at 80°C for 30min, wherein the molecular weight of PEG is 6,000;

[0050] c. Mix the agar solution obtained in step a with the PEG solution obtained in step b in a water bath and stir continuously. After the stirring time is maintained for 15 minutes, stop stirring to obtain a suspension with a white precipitate. After standing for 25 minutes, a white color appears precipitation;

[0051] d. Take the suspension obtained in step c out of the water bath, let it stand, and cool it at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com