A kind of multiple copolymer cement grinding aid and preparation method thereof

A technology of cement grinding aids and multi-component copolymers, which is applied in the fields of multi-component copolymer cement grinding aids and preparation, cement grinding aids and preparations, and can solve the problem that cannot fully meet the diversified and high-level needs of the market, and the enhancement effect is limited , pollute the environment and other issues, to achieve the effect of promoting the use of industrialization, improving the effect of grinding aid, and reducing electrostatic adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

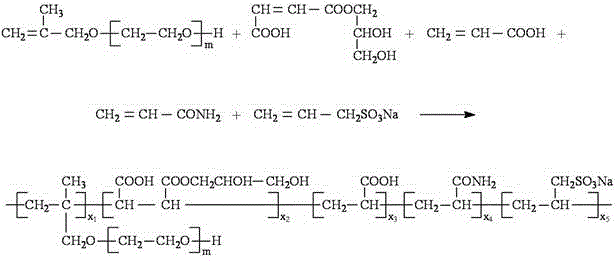

Method used

Image

Examples

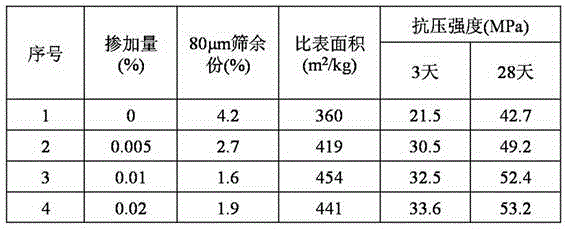

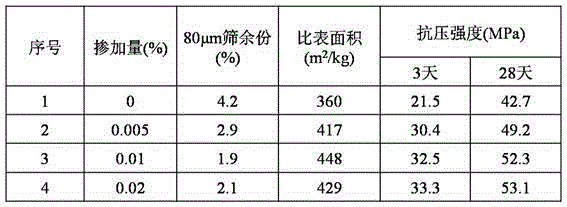

Embodiment 1

[0028] Add 10 parts of maleic anhydride and 9.5 parts of glycerol into the reactor, stir and raise the temperature to 110°C, react for 2 hours, and then add 190 parts of methallyl alcohol polyoxyethylene ether (average molecular weight 2400) and 34 isopropanol. Add 0.4 parts of ferrous ammonium sulfate and 66 parts of water into the reactor, stir and raise the temperature to 80°C, add 6 parts of sodium propylene sulfonate, 6 parts of acrylamide, 10 parts of acrylic acid, and 30 parts of water into a certain container to dissolve called acrylic acid , A mixed solution of acrylamide and sodium allyl sulfonate. The mixed solution of acrylic acid, acrylamide, sodium allyl sulfonate and hydrogen peroxide were respectively added dropwise to the reactor, the reaction temperature was maintained, and the dropping rate was controlled. The dripping was completed in 3 hours, and the temperature was maintained for another 1 hour. Add 8 parts of triisopropanolamine and 7 parts of sodium hydr...

Embodiment 2

[0032] Add 10 parts of maleic anhydride and 9.5 parts of glycerol into the reactor, stir and raise the temperature to 110°C, react for 2 hours, and then add 190 parts of methallyl alcohol polyoxyethylene ether (average molecular weight 2400) and 34 isopropanol. Add 0.4 parts of ferrous ammonium sulfate and 66 parts of water into the reactor, stir and raise the temperature to 80℃, add 6 parts of sodium propylene sulfonate, 8 parts of acrylamide, 8 parts of acrylic acid, and 30 parts of water into a certain container to dissolve called acrylic acid , A mixed solution of acrylamide and sodium allyl sulfonate. The mixed solution of acrylic acid, acrylamide, sodium allyl sulfonate and hydrogen peroxide were respectively added dropwise to the reactor, the reaction temperature was maintained, and the dropping rate was controlled. The dripping was completed in 3 hours, and the temperature was maintained for another 1 hour. Add 8 parts of triisopropanolamine and 7 parts of sodium hydrox...

Embodiment 3

[0036] Add 10 parts of maleic anhydride and 9.5 parts of glycerol into the reactor, stir and raise the temperature to 110°C, react for 2 hours, and then add 190 parts of methallyl alcohol polyoxyethylene ether (average molecular weight 2400) and 34 isopropanol. Add 0.4 parts of ferrous ammonium sulfate and 66 parts of water into the reactor, stir and heat up to 80°C, add 6 parts of sodium propylene sulfonate, 10 parts of acrylamide, 6 parts of acrylic acid, and 30 parts of water into a certain container to dissolve called acrylic acid , A mixed solution of acrylamide and sodium allyl sulfonate. The mixed solution of acrylic acid, acrylamide, sodium allyl sulfonate and hydrogen peroxide were respectively added dropwise to the reactor, the reaction temperature was maintained, and the dropping rate was controlled. The dripping was completed in 3 hours, and the temperature was maintained for another 1 hour. Add 8 parts of triisopropanolamine and 7 parts of sodium hydroxide to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com