Method for improving denitrification rate of acrylonitrile waste water

A technology for acrylonitrile wastewater and denitrification rate, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of effluent COD or TN not up to standard, low removal efficiency, etc. , to achieve the effect of improving TN removal rate, low operating cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

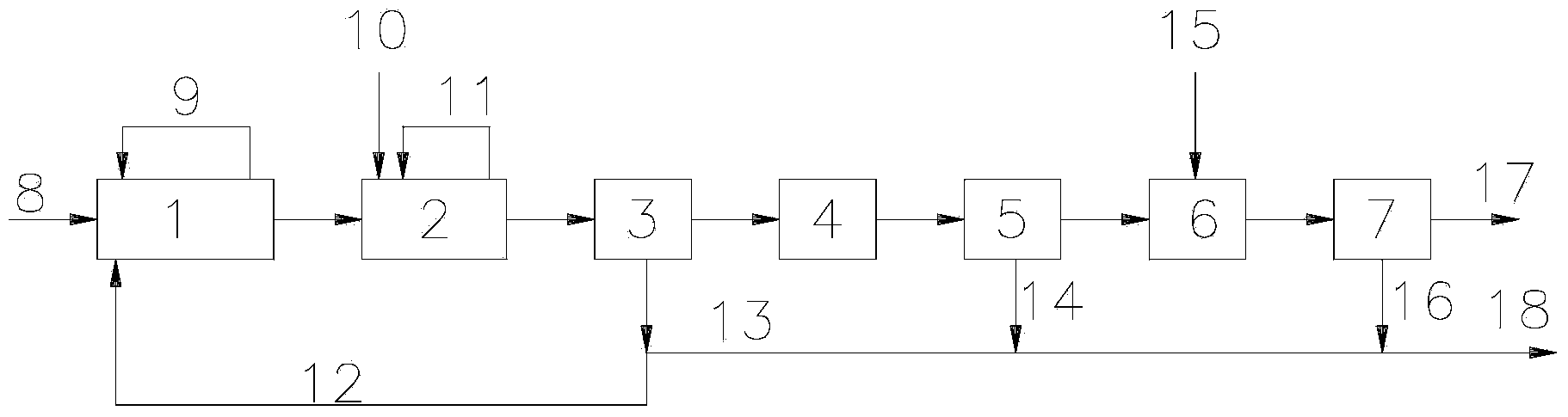

Method used

Image

Examples

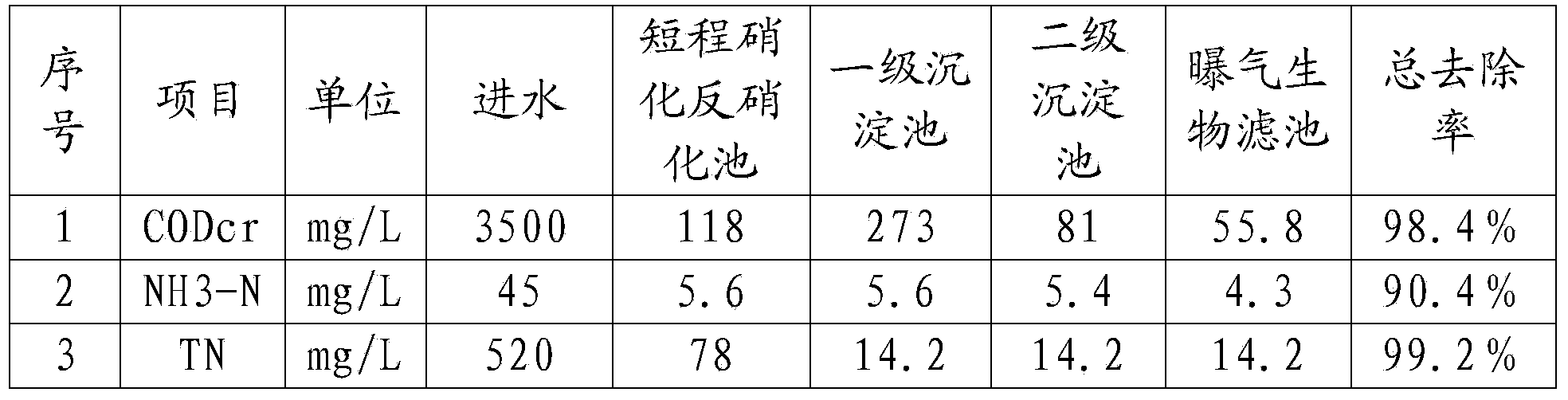

Embodiment 1

[0036] Water quality of an acrylonitrile wastewater: COD is 3500mg / L, NH 3 -N is 45 mg / L and TN is 520 mg / L.

[0037] The acrylonitrile wastewater first enters the short-range nitrification and denitrification tank, and is mixed with the internal circulation reflux liquid and the sedimentation tank reflux sludge; the air lifter is used to circulate the mixed liquid internally, and the internal circulation flow rate is 30 times that of the influent water; the DO in the control tank is 0.5mg / L, the pH is 7.8, the temperature is 30°C, and the sludge concentration is 8000mg / L.

[0038] The effluent of the short-range nitrification and denitrification tank enters the anoxic tank, and methanol is added to the tank. The dosage is calculated according to the carbon-nitrogen ratio of 5:1. The DO of the anoxic tank is 0.3mg / L, the pH is 7.8, and the temperature is 35 ℃, the sludge concentration is 8000mg / L, a submersible agitator is installed in the anoxic tank to realize the internal...

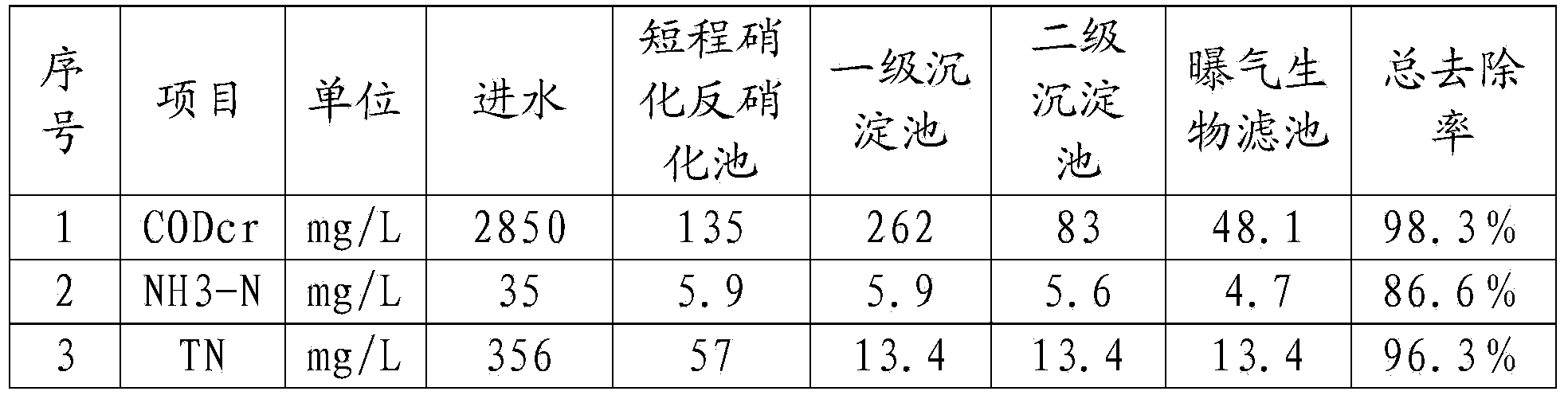

Embodiment 2

[0044] Water quality of an acrylonitrile wastewater: COD is 2850mg / L, NH 3 -N is 35 mg / L and TN is 356 mg / L.

[0045] The acrylonitrile wastewater first enters the short-range nitrification and denitrification tank, and is mixed with the internal circulation reflux liquid and the sedimentation tank reflux sludge; the air lifter is used to circulate the mixed liquid internally, and the internal circulation flow rate is 25 times that of the influent water; the DO in the control tank is 0.4mg / L, the pH is 8.0, the temperature is 20°C, and the sludge concentration is 6000mg / L.

[0046] The effluent of the short-range nitrification and denitrification tank enters the anoxic tank, and methanol is added to the tank. The dosage is calculated according to the carbon-nitrogen ratio of 4:1. The DO of the anoxic tank is 0.2mg / L, the pH is 7.5, and the temperature is 25 ℃, the sludge concentration is 6000mg / L, a submersible agitator is installed in the anoxic tank to realize the internal...

Embodiment 3

[0052] The mixed water quality of a certain acrylonitrile wastewater and other wastewater: COD is 1500mg / L, NH 3 -N is 33 mg / L and TN is 220 mg / L.

[0053] The acrylonitrile wastewater first enters the short-range nitrification and denitrification tank, and is mixed with the internal circulation reflux liquid and the sedimentation tank reflux sludge; the air lifter is used to circulate the mixed liquid internally, and the internal circulation flow rate is 10 times the influent; the DO in the control tank is 0.3mg / L, the pH is 7.5, the temperature is 15°C, and the sludge concentration is 4000mg / L.

[0054] The effluent of the short-range nitrification and denitrification tank enters the anoxic tank, and methanol is added to the tank. The dosage is calculated according to the carbon-nitrogen ratio of 3:1. The DO of the anoxic tank is 0.1mg / L, the pH is 7.2, and the temperature is 20 ℃, the sludge concentration is 4000mg / L, a submersible agitator is installed in the anoxic tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com