Circulating fluidized crystallization control reaction device for wastewater phosphorus synergy crystallization and dynamic monitoring and regulating method thereof

A reaction device and a crystallization control technology, applied in the field of agricultural resources and environment, can solve the problems of limited crystallization efficiency, difficulty in monitoring the supersaturated state of struvite crystallization, and inability to effectively control the struvite crystallization granulation process, etc., so as to improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

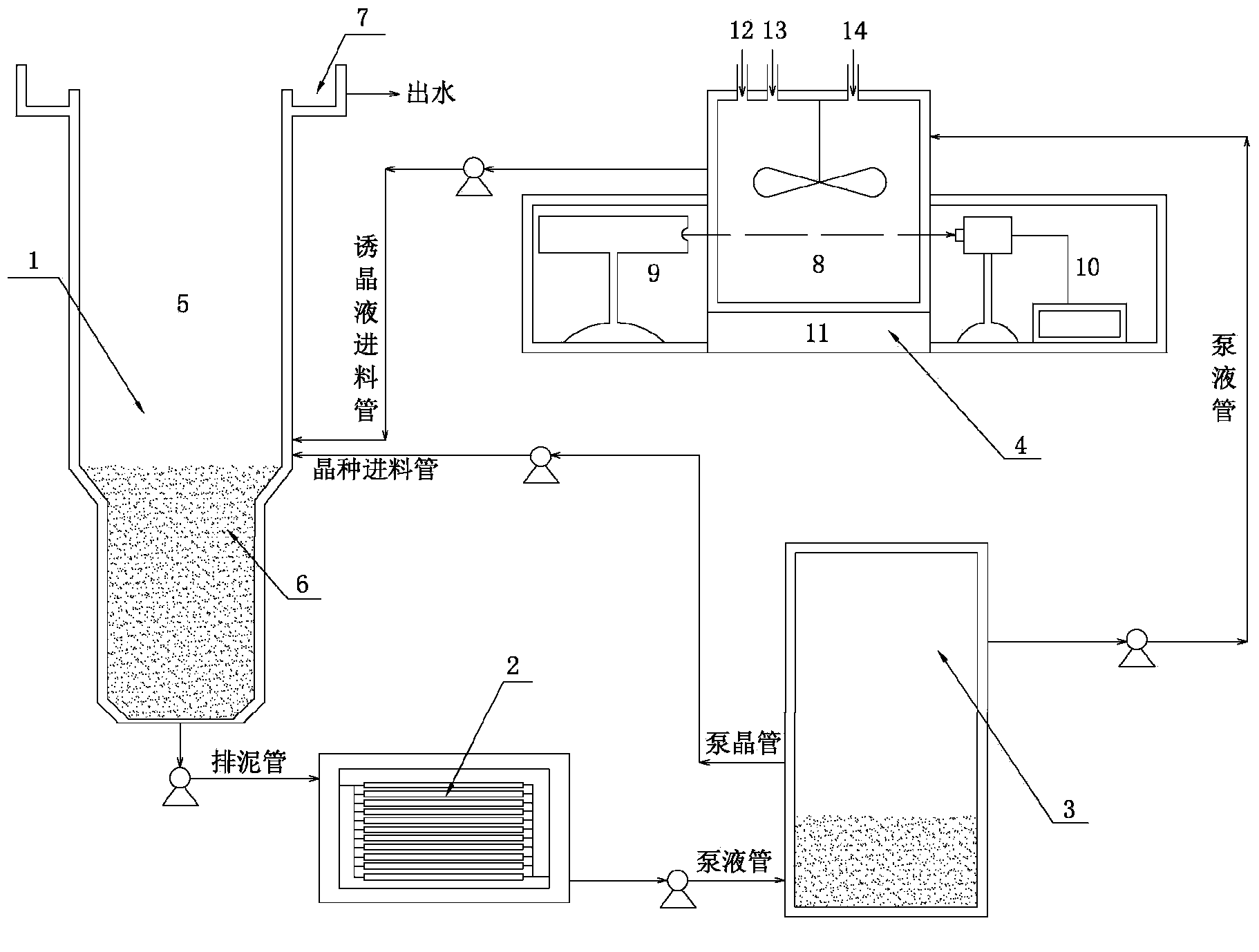

[0049] Example 1, Circulating Fluidized Crystallization Control Reactor for Wastewater Phosphorus Synergistic Crystallization

[0050]Such as figure 1 As shown, the circulating fluidized crystallization control reaction device of the wastewater phosphorus synergistic crystallization of the present invention includes a crystallization controller 1, a bag filter 2, a saturated liquid buffer tank 3 and a dynamic monitoring tank 4; wherein, from top to bottom, The crystallization regulator 1 includes a crystal growth tank 5 and a crystal collection tank 6, and an overflow weir 7 is connected to the top opening of the crystal growth tank 5, and the overflow weir 7 has an equilateral triangle structure with inner and outer double layers. The mud discharge pipe of the crystal collection tank 6 communicates with the bag filter 2; the liquid outlet of the bag filter 2 communicates with the saturated liquid buffer tank 3. The solid outlet of the saturated liquid buffer tank 3 is connec...

Embodiment 2

[0053] Example 2. Dynamic monitoring and regulation of phosphorous synergistic crystallization in wastewater

[0054] Utilize the circulating fluidized crystallization control reaction device of wastewater phosphorus synergistic crystallization in embodiment 1 to carry out dynamic monitoring and regulation, wherein, the height-diameter ratio of the crystal growth tank 5 of crystallization regulator 1 in the reaction device is 4:1, The height-to-diameter ratio of the crystal collection tank is 1:1, the height-to-diameter ratio of the bag filter 2 is 1:1; the height-to-diameter ratio of the saturated liquid buffer tank 3 is 3:1; The height-to-diameter ratio is 2:1, with a built-in mechanical stirrer with a stirring rate of 30-90r / min.

[0055] Regulate the phosphorus content (calculated as phosphorus) in the wastewater to 200mg / L, add it to the crystallization liquid tank 8, and mix it with magnesium chloride solution at a molar ratio of magnesium ion to phosphate of 1:1, contro...

Embodiment 3

[0057] Example 3. Dynamic monitoring and regulation of phosphorous synergistic crystallization in wastewater

[0058] Utilize the circulating fluidized crystallization control reaction device of wastewater phosphorus synergistic crystallization in embodiment 1 to carry out dynamic monitoring and regulation, wherein, the height-diameter ratio of the crystal growth tank 5 of crystallization regulator 1 in the reaction device is 3:1, The height-to-diameter ratio of the crystal collection tank 6 is 2:1, the height-to-diameter ratio of the bag filter 2 is 0.5:1; the height-to-diameter ratio of the saturated liquid buffer tank 3 is 2:1; the crystal-induced liquid tank 8 in the dynamic monitoring tank 4 The height-to-diameter ratio is 1:1, and the built-in mechanical stirrer has a stirring rate of 90-180r / min.

[0059] Regulate the phosphorus content (calculated as phosphorus) in the waste water to 500mg / L, add it to the crystallization liquid tank 8, mix it with the magnesium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com