Aluminum-wood-plastic composite integrated decorative plate and preparation method thereof

An integrated board and aluminum-wood technology, applied in the direction of wood layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of endangering the physical and mental health of workers, ungluing, high safety hazards, etc., to save raw materials and labor, reduce The production cost and the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

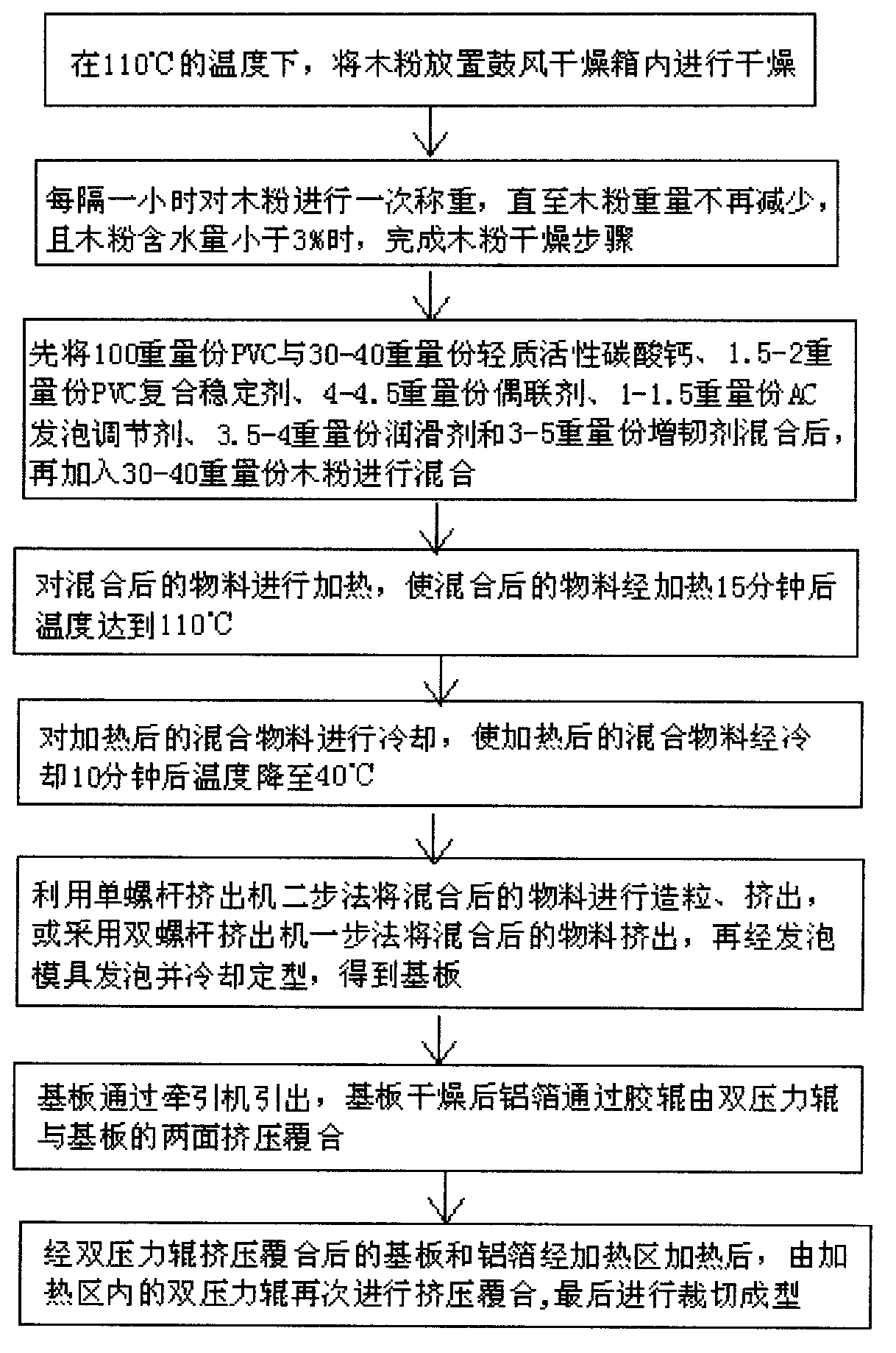

[0045] like figure 2 As shown, the preparation method of the aluminum-wood-plastic composite decorative integrated board of the present invention comprises the following steps:

[0046] A1: At a temperature of 110°C, place wood flour or other plant fiber powder in a blast drying oven for drying, and the particle size of wood flour or other plant fiber powder is 80-120 mesh;

[0047] A2: Weigh the wood powder every hour until the water content of the wood powder is less than 3%, then complete the wood powder drying step;

[0048] B1: Since the loose wood powder will affect the mixing and plasticizing uniformity of PVC and other additives, resulting in a decline in product quality, it is necessary to add a stabilizer. First, 100 parts by weight of PVC and 30-40 parts by weight of light active calcium carbonate , 1.5-2 parts by weight of PVC composite stabilizer, 4-4.5 parts by weight of coupling agent, 1-1.5 parts by weight of AC foam regulator, 3.5-4 parts by weight of lubric...

Embodiment 1

[0056] (1) At a temperature of 100°C, place wood powder with a particle size of 80 meshes in a blast drying oven for drying, and weigh the wood powder every hour until the weight of the wood powder no longer decreases. After drying for 3 hours, when the water content of the wood flour is less than 3%, the wood flour drying step is completed;

[0057] (2) 100 parts by weight of PVC and 30 parts by weight of light activated calcium carbonate, 1.5 parts by weight of PVC composite stabilizer, 4 parts by weight of coupling agent, 1 part by weight of AC foam regulator, 3.5 parts by weight of lubricant and 3 parts by weight of After mixing the toughening agent, add 30 parts by weight of wood flour and mix; the PVC model is SG-700, the particle size of light active calcium carbonate is 900 mesh, the PVC composite stabilizer adopts lead salt stabilizer, and the coupling agent can adopt The varieties include amino acid grease, maleic anhydride modified polypropylene agent, acrylic resin...

Embodiment 2

[0076] (1) At a temperature of 120°C, place the wood powder with a particle size of 120 mesh in a blast drying oven for drying, and weigh the wood powder every hour until the weight of the wood powder no longer decreases. After drying for 3 hours, when the water content of the wood flour is less than 3%, the wood flour drying step is completed;

[0077] (2) 100 parts by weight of PVC and 40 parts by weight of light activated calcium carbonate, 2 parts by weight of PVC composite stabilizer, 4.5 parts by weight of coupling agent, 1.5 parts by weight of AC foam regulator, 4 parts by weight of lubricant and 5 parts by weight of After mixing the toughening agent, add 40 parts by weight of wood flour and mix; the PVC model is SG-700, the particle size of light active calcium carbonate is 1050 mesh, the PVC composite stabilizer adopts lead salt stabilizer, and the coupling agent can adopt The varieties include amino acid grease, maleic anhydride modified polypropylene agent, acrylic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com