Linear cutting guide wheel assembly with waterproof blades

A wire cutting and fan blade technology, which is used in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of bearing damage, shortened life, and not very good results, and achieve improved service life, good waterproof protection, and good The effect of the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

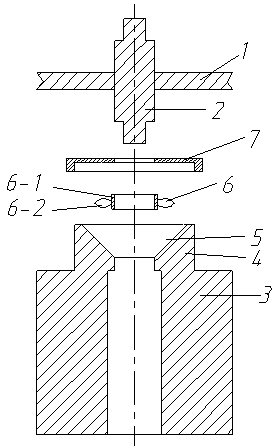

[0018] see figure 1 , as can be seen from the figure, the waterproof structure of the metal wire cutting guide wheel assembly with fan blades of the present invention includes a guide wheel 1, a guide wheel shaft 2, a bearing and a guide wheel seat 3 (for convenience of expression, figure 1 The bearing is not drawn in the figure), the guide wheel 1 is installed on the guide wheel shaft 2, and the two ends of the guide wheel shaft are installed on the corresponding bearings. Outside the bearing is the guide wheel seat 3, that is, the bearing seat of the bearing. The guide wheel seat 3 extends toward the middle part of the guide wheel end face to form a waterproof seat 4, and the waterproof seat 4 is provided with an accommodation chamber 5 with an opening facing the guide wheel, and a water retaining fan blade assembly 6 is arranged in the accommodation chamber 5 , The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com