Solution atomization device for urea pyrolysis ammonia production process

A solution atomization and atomization nozzle technology, which is applied in the field of flue gas urea denitrification, can solve the problems of aggravating the crystallization at the bottom of the pyrolysis furnace, reducing the flow rate of atomizing air, reducing the atomization effect, etc., and reducing the atomization spray radius , Increase the air flow rate, improve the effect of atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

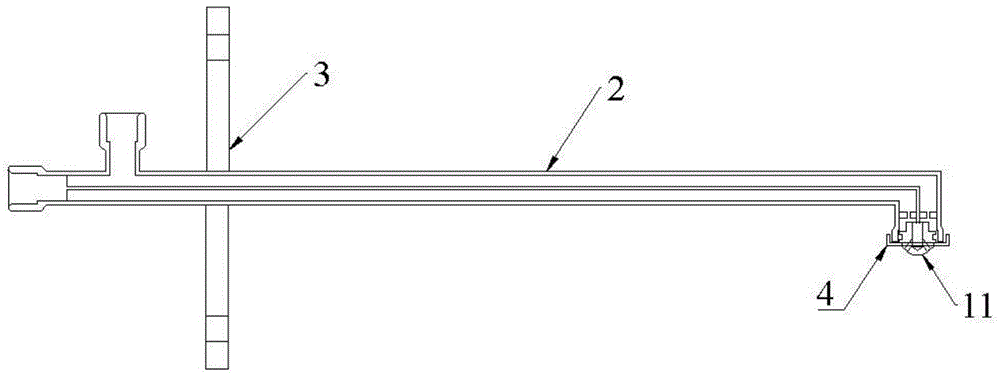

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the accompanying drawings are only used to explain the present invention, and are schematic descriptions of the embodiments of the present invention, but should not be construed as limiting the present invention.

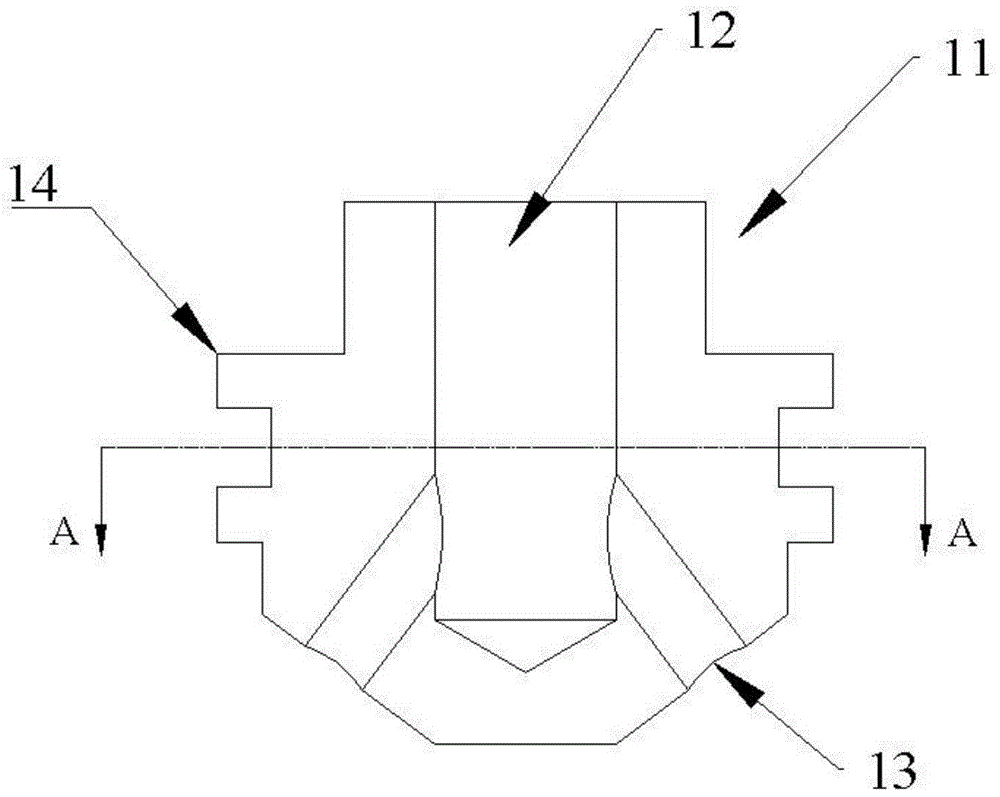

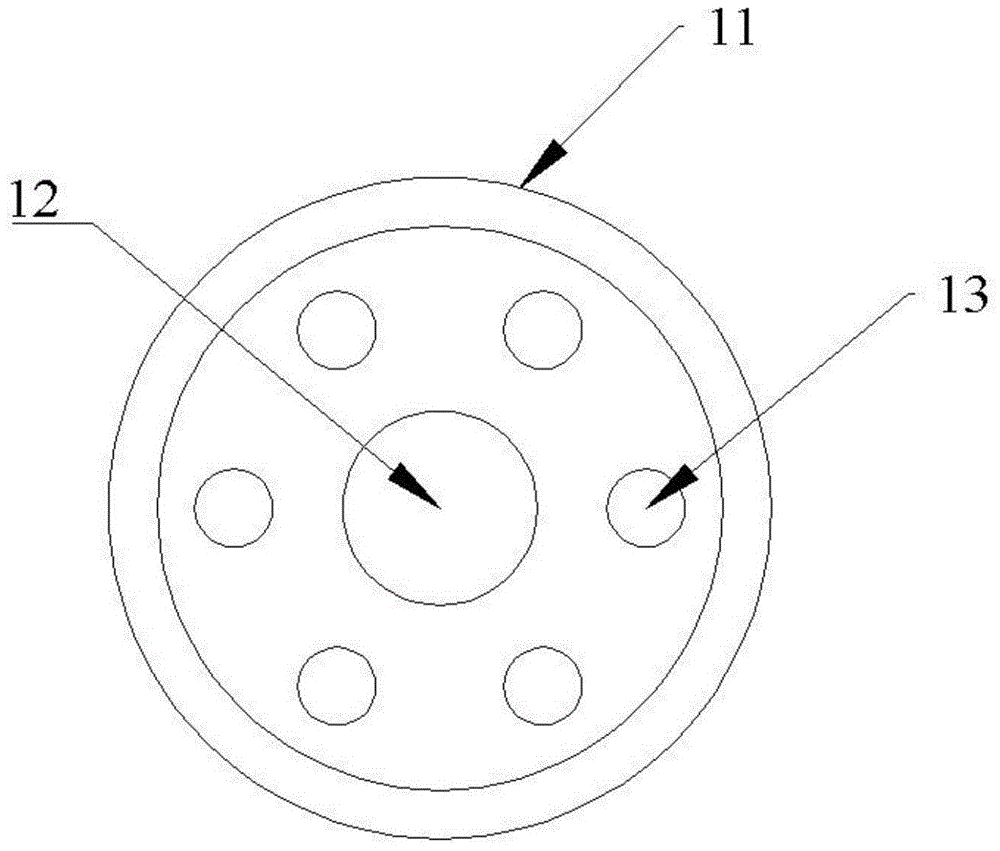

[0029] Such as figure 1 , figure 2 As shown, the atomizing nozzle of the present invention includes: a nozzle body 11, a chamber 12 is arranged on the nozzle body 11, and a plurality of injection holes 13 are arranged on the side wall of the injection end of the nozzle body 11, wherein the plurality of injection holes 13 are respectively It communicates with the chamber 12, and the angles between the multiple injection holes 13 and the central axis of the nozzle body 11 are all less than 60°, so that the spray coverage radius of the atomizing nozzle is smaller than the distance from the atomizing nozzle to the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com