Filter arrangement and method for producing a filter receptacle

A filter assembly, filter technology, applied in chemical instruments and methods, membrane filters, separation methods, etc., can solve problems such as limiting filter housing and assembly geometry and installation orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

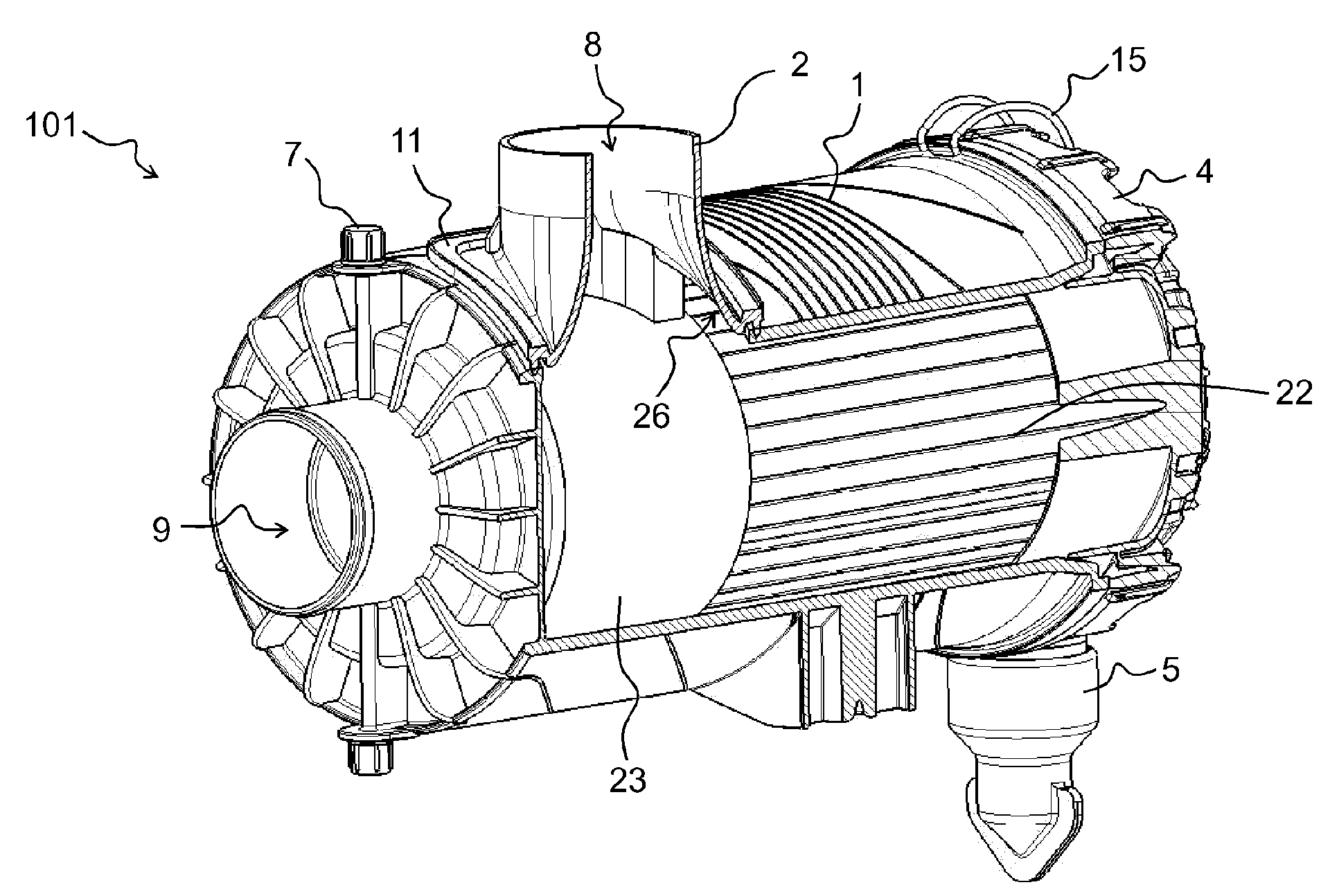

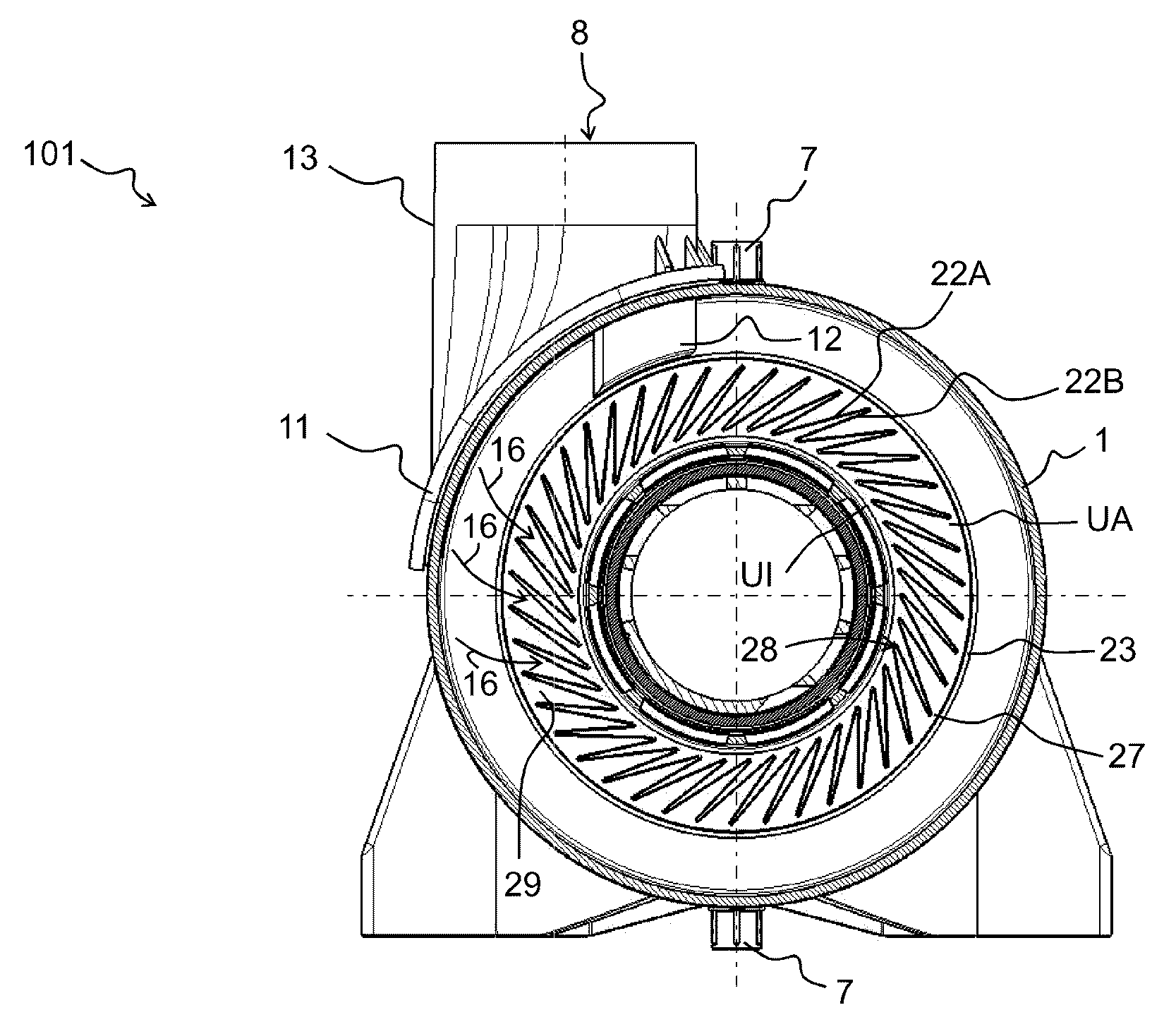

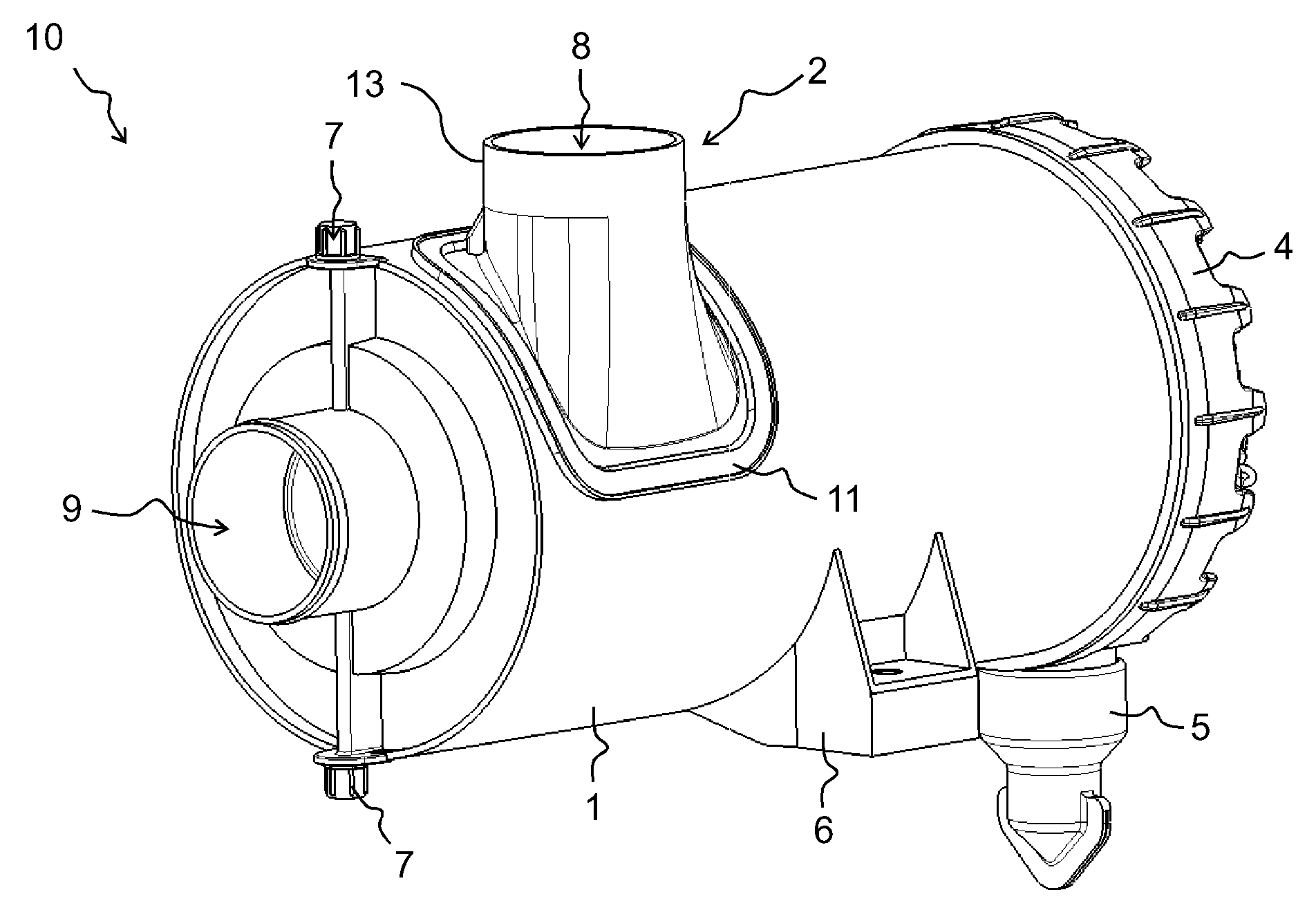

[0032] figure 1 A perspective view of a first embodiment of a filter holder and a filter assembly is shown. exist figure 2 with 3 A perspective illustration of housing parts such as filter housing and filter cover as well as individual inlet connections is shown in . Figure 4 with 5 shows a side view of the filter holder, while Figure 7A partially disassembled perspective illustration of a corresponding filter assembly with the filter elements used is shown.

[0033] first in figure 1 The filter holder 10 is visible in perspective. The filter holder 10 here comprises a substantially cylindrical housing part 1 and a housing cover 4 . The housing part is, for example, a plastic molded part and can be produced by injection molding or other known manufacturing processes. An inflow connection 2 is mounted on the outside of the housing part 1 . The inlet connection 2 comprises a cylindrical section 13 protruding from the housing 1 (which protrudes from the fastening surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com