Hot airflow drying/disinfecting pipe

A disinfection tube and hot air flow technology, applied in drying, drying machine, heating, etc., can solve the problems of slow initial thermal diffusion, long time required for temperature control, and power consumption, etc., to achieve fast heat transfer, disinfection or Good drying effect and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

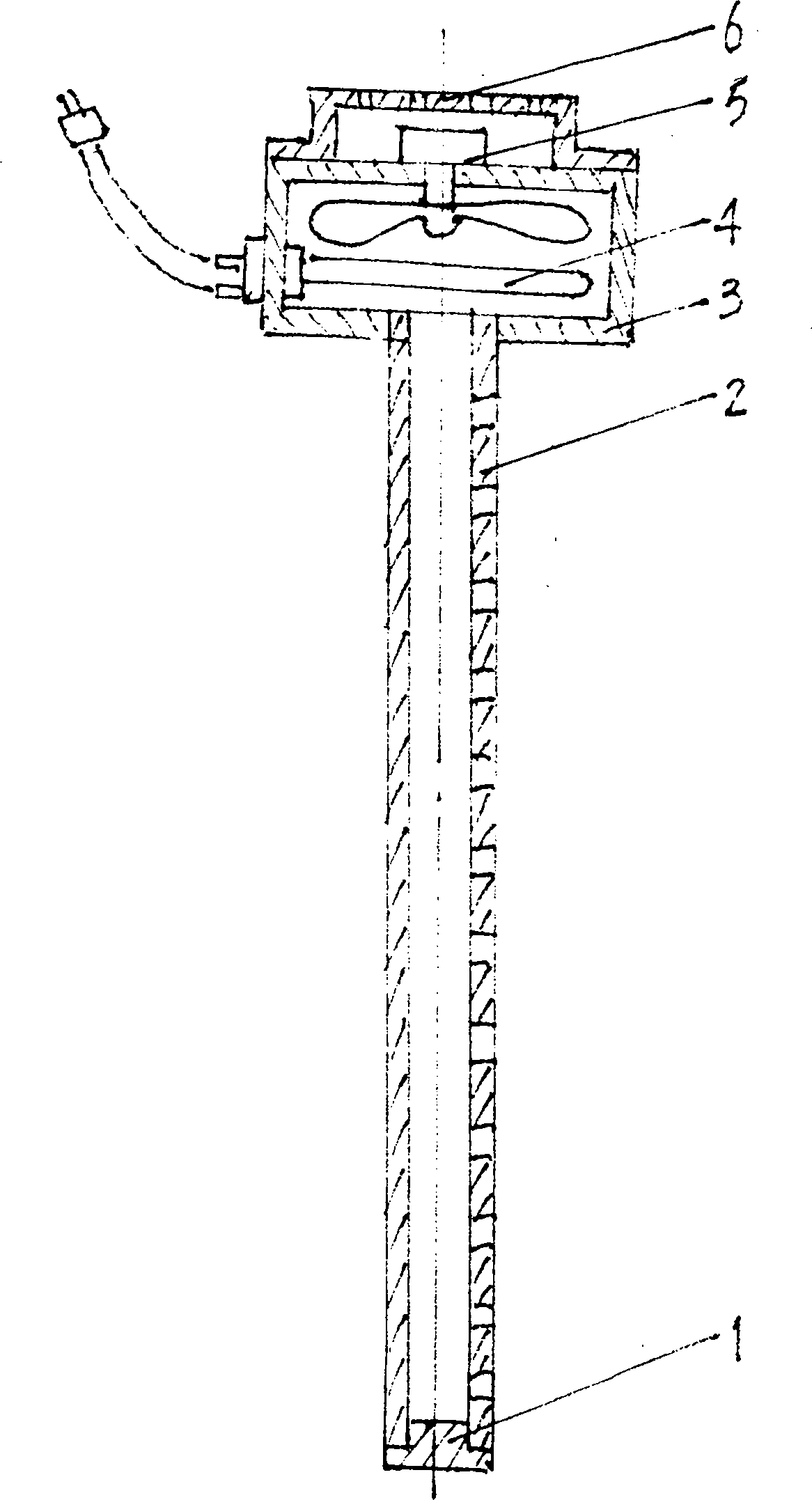

[0010] 1 in the figure, the heating element (4) and the fan (5) are installed in the heating box (3), and the motor of the fan (5) is covered with a cover (6) for safety, and a heat dissipation pipe is connected to the lower end of the heating box (3) (2), according to the height design of the box body, it is generally about the same height as the inside of the box body. Multiple heat dissipation holes are arranged on the side of the heat dissipation pipe (2), and the lower end of the heat dissipation pipe (2) is blocked with a plug (1). Depending on the size of the body volume, a combination of 2-4 cooling pipes (2) can also be set.

[0011] When in use, turn on the power switch and adjust the temperature control knob. At this time, the heating element (4) works, and the heat accumulated in the heat dissipation pipe (2) is blown into the heat dissipation pipe (2) through the fan (5), and accumulated in the heat dissipation pipe (2). The heat of the tube (2) is sprayed into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com