Rotary vacuum loosening and dampening machine and its loosening and dampening method

A loose moisture-recovering and rotating technology, which is applied in the direction of tobacco preparation, application, and tobacco, can solve the problems of high tobacco leaf crushing rate, tobacco leaf crushing, and tobacco leaves can not be heated evenly, and achieve the effect of improving the penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

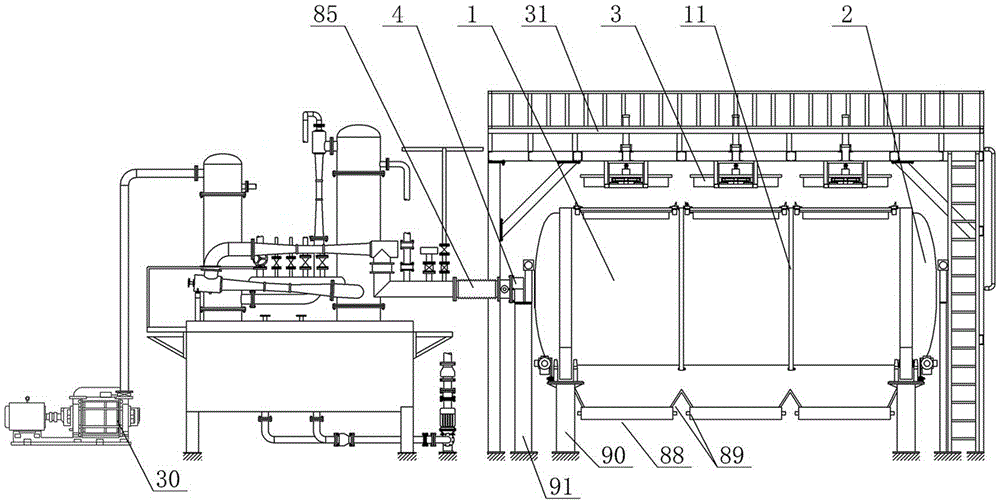

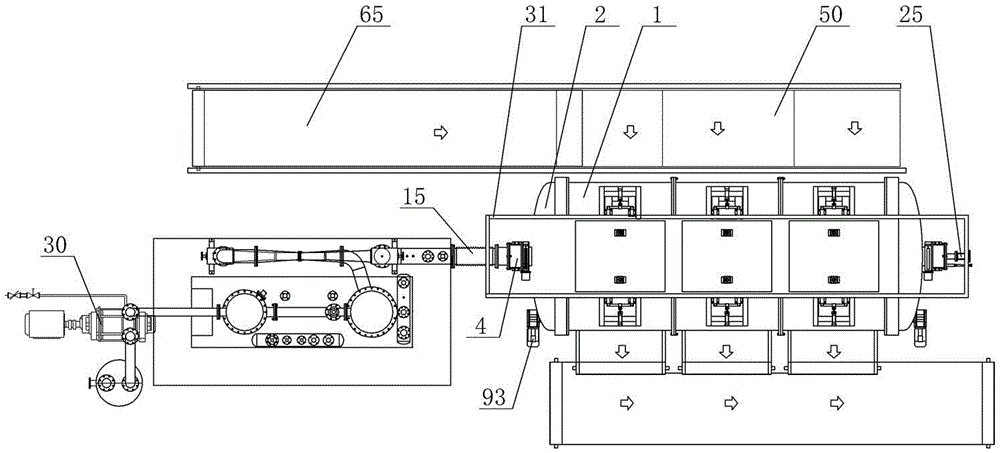

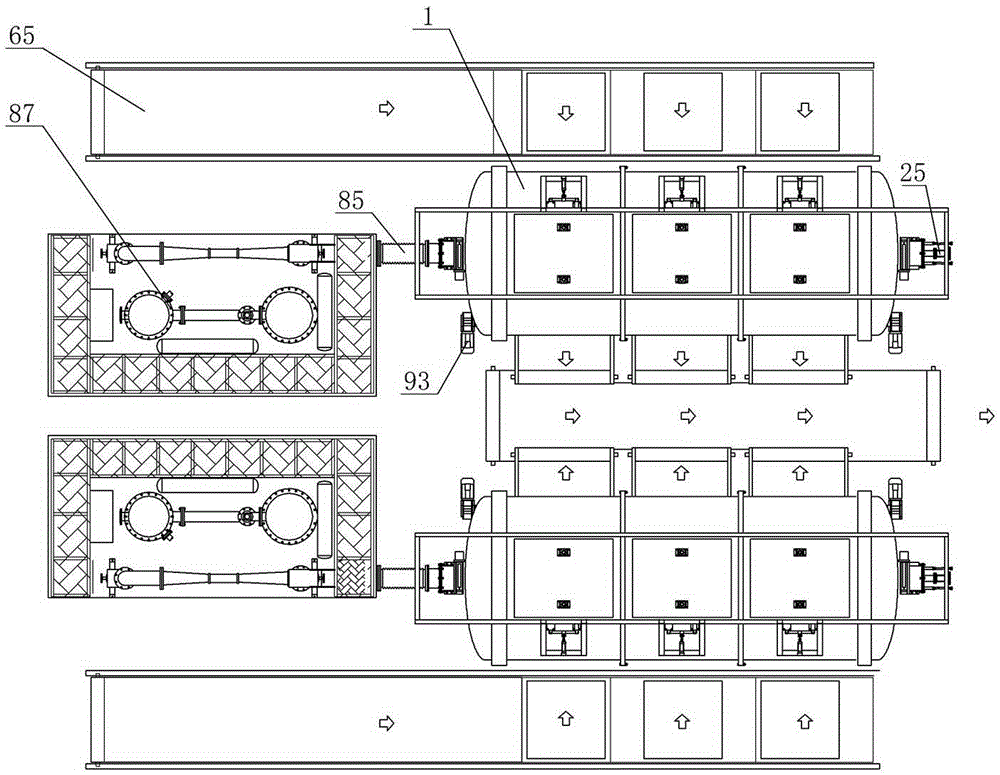

[0063] Embodiment 1: see figure 1 Figure 21 , a rotary vacuum loosening and dampening machine, including a feeding conveying device, a discharging conveying device, a loosening dampening cylinder, a cylinder driving device for a loosening dampening cylinder, a humidifying device, a vacuum system, a rotary sealing device and a control device, its characteristics Yes: the cylinder body 1 of the loose moisture resurgence cylinder is connected with the cylinder body driving device through a power transmission mechanism, and the power transmission mechanism and the cylinder body driving device of the cylinder body driving device are provided at one end, or both ends, or in the middle of the cylinder body 1 The output shaft of the power machine is connected, and the two ends of the cylinder body 1 are provided with a rotary sealing device that communicates with the inner cavity of the cylinder body 1. The evacuation pipe of the vacuum system 87 and the humidification flushing pipel...

Embodiment 2

[0094] Example 2: see Figure 7 , the structure of embodiment two is basically the same as that of embodiment one. The same symbols in the figure represent the same meaning, and the similarities will not be repeated. A counterweight 12 is installed, and the position where the counterweight 12 is installed is determined according to the actual rotation of the cylinder body 1 of the loose dampening cylinder of the moisture conditioner.

Embodiment 3

[0095] Embodiment 3: see Figure 1 to Figure 7 , embodiment three is basically the same as embodiment one, and the same symbols in the figure represent the same meaning, and the similarities will not be repeated. The difference is that the cylinder 1 is a combined cylinder, and its structure is that the middle section is N The cylindrical cylinders are connected by flanges, an integer of N≥2, a sealing ring is provided between two adjacent flanges, each cylindrical cylinder is provided with a sealing door, and guides are provided on both sides of the sealing door. The big ends of the material cone 13 and two adjacent material guide cones 13 are sealed and connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com