Chicken cartilage composite functional dog food and preparation method thereof

A functional, cartilage technology, applied in applications, animal feed, animal feed, etc., can solve the problems of unscientific and reasonable matching of nutrients, affecting the health of pet dogs, and unbalanced nutrition of pet dogs, so as to achieve activity and playfulness Enhance and improve intestinal health and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

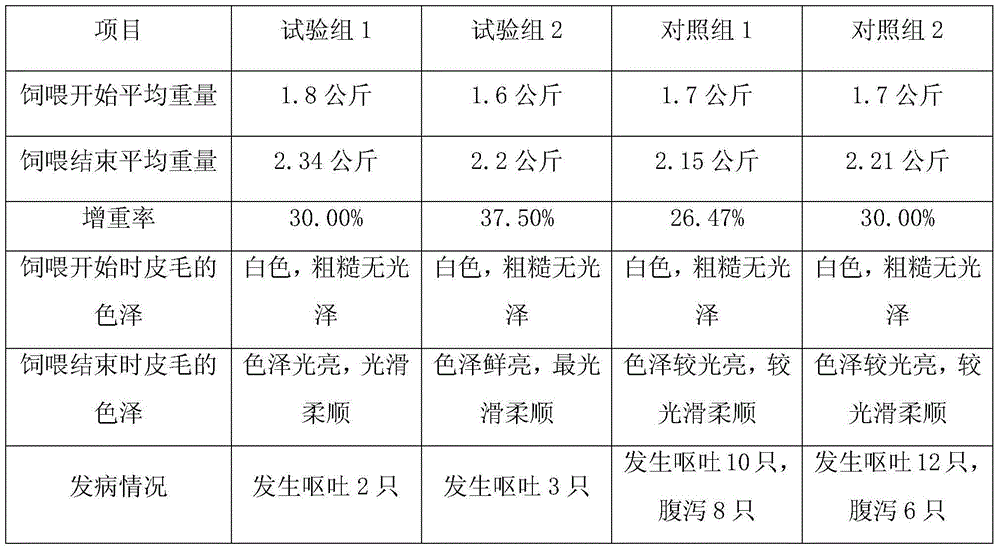

Examples

preparation example Construction

[0027] A preparation method of the above-mentioned nutritionally balanced chicken cartilage composite functional dog food, comprising the steps of:

[0028] a Weigh each raw material according to the above weight ratio; ultrafinely pulverize the weighed raw materials prebiotics, essential vitamins and minerals to 80-100 meshes, then mix, and add an appropriate amount of hot water at 60°C during the mixing process , after mixing evenly, carry out the first aging, and then granulate; after the granulation, carry out the second aging, then cool and dry, and finally obtain the semi-finished product through superfine pulverization.

[0029] In this step, the mixing is carried out in a blade-belt mixer, hot water is added to the raw materials in the form of spray, and the mixed raw materials are cured for the first time through the double-layer thermal insulation steam modulator, and the double-layer thermal insulation steam The modulator can be the extended double-layer thermal ins...

Embodiment 1

[0036] aWeigh 53 parts of fresh chicken, 10 parts of cartilage, 1.5 parts of vegetable oil, 14 parts of meat by-products, 21.3 parts of edible colloid, 0.1 part of prebiotic powder, 10.03 parts of vitamin B, 0.02 parts of vitamin B6, 0.03 parts of vitamin B120.03 part, 0.02 part of sodium humate, and 0.1 part of fructooligosaccharide.

[0037] b Superfinely pulverize the prebiotic powder, vitamin B1, vitamin B6, vitamin B12, and sodium humate to 80-100 meshes respectively, and then mix them. During the mixing process, add an appropriate amount of hot water at 60°C, and mix well before proceeding. The first aging, and then granulation; the second aging after granulation, then cooling and drying, and finally the semi-finished product is obtained through ultrafine grinding.

[0038] c Thaw fresh chicken, cartilage and meat by-products, cut them into sections, and trim them; clean the trimmed fresh chicken, cartilage, and meat by-products, let them stand for 10-15 minutes, and the...

Embodiment 2

[0042] a Weigh 50 parts of fresh chicken, 8 parts of cartilage, 1 part of vegetable oil, 10 parts of meat by-products, 18 parts of edible gelatin, 0.1 part of prebiotic powder, 10.03 parts of vitamin B, 0.02 parts of vitamin B6, and 120.03 parts of vitamin B part, 0.02 part of sodium humate, and 0.1 part of fructooligosaccharide.

[0043]b Superfinely pulverize the prebiotic powder, vitamin B1, vitamin B6, vitamin B12, and sodium humate to 80-100 meshes respectively, and then mix them. During the mixing process, add an appropriate amount of hot water at 60°C at the same time. First ripening, then granulation; second ripening after granulation, then cooling and drying, and finally ultrafine pulverization to obtain a semi-finished product.

[0044] c Thaw fresh chicken, cartilage and meat by-products, cut them into sections, and trim them; clean the trimmed fresh chicken, cartilage, and meat by-products, let them stand for 10-15 minutes, and then put them into the steam stove an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com